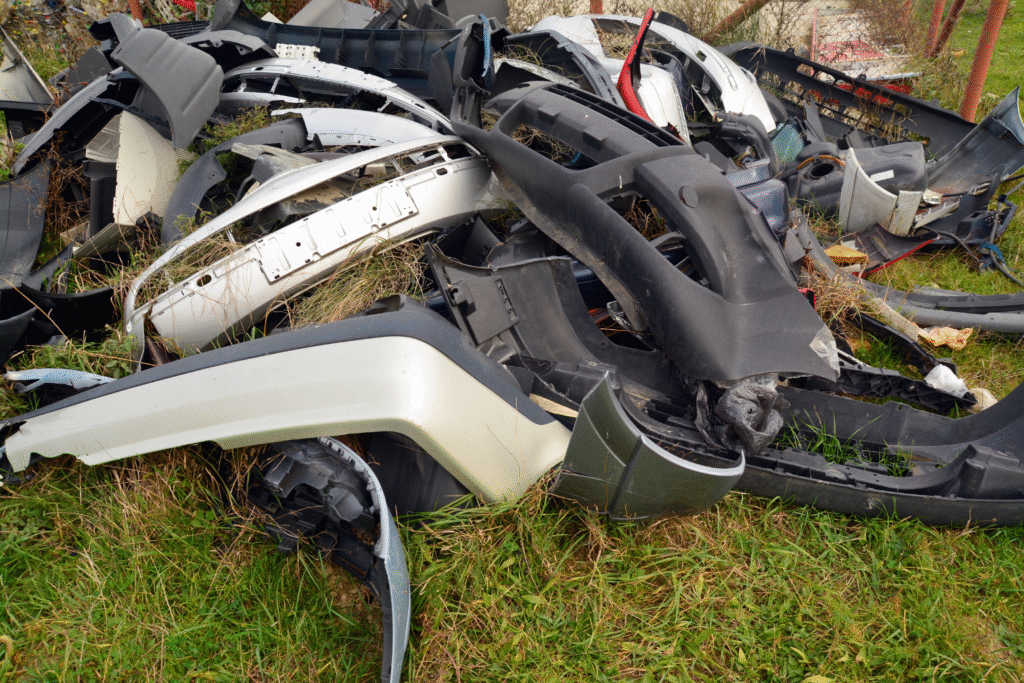

Assuring Long-Term Durability of Plastics in Automotive Applications

Automotive plastics face extreme environmental stress over their service life-prolonged exposure to

full-spectrum sunlight (UV-visible-IR), temperature fluctuations, and moisture. These forces trigger multiple

degradation modes, including:-

- Photodegradation

- Oxidative Embrittlement

- Surface crazing and microcracking

- Gloss loss and chalking

- Yellowing and haze formation

- Structural integrity compromis

Our masterbatches are validated for real-world durability through accelerated laboratory weathering.

specifically using the Xenon Arc Weathering Chamber, a benchmark tool simulating long-term

environmental effects in weeks instead of years.

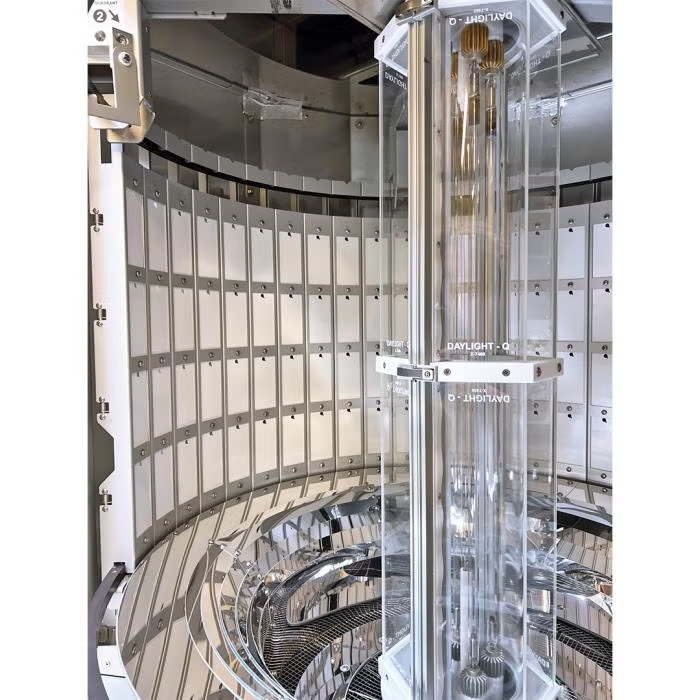

A New Standard in Xenon Weatherability Testing

Xenon Arc Weathering Testing chamber is a high-capacity, air-cooled, rotating rack xenon arc test chamber designed for advanced R&D and quality validation. It replicates the entire solar spectrum (295-800 nm) using 4200 W xenon arc lamps and optical filter systems, exposing plastic specimens to the same aging stresses found in Florida, Arizona, or other high-degradation outdoor zones.

Key Technical Capabilities:

- Specimen Capacity: Up to 164 samples (51 102 mm) or 96 samples (67 145 mm)

- Chamber Type: Fully automated rotating rack with precise irradiance and temperature control

- Irradiance Control: 340 nm, 420 nm, and TUV via patented SOLAR EYE system.

- Water Spray: Dual front and back programmable nozzles for thermal shock simulation.

- Relative Humidity Control: Precision RH management to simulate tropical or humid regions.

- Black Panel Temperature: Adjustable from 25 C to 105 C, simulating real-time surface heating

Realistic Environmental Simulation

1. Full-Spectrum Xenon Lamps

- LIGHT/YEAR xenon arc lamps provide the most realistic spectral match to sunlight.

- Lamp longevity: 8000 hours (normal irradiance) / 2000 hours (high irradiance)

- Air-cooled system: Eliminates the need for high-cost water-cooling infrastructure

2. Optical Filter Technology

Customizable filters allow simulation of specific environments or standards:-

- Daylight-Q/F/B: Outdoor conditions (ASTM Type I & II) – bumpers, trims, exterior panels

- Window Glass-Q/B/SL/SF-5: Interior exposure like dashboards or pillars

- Extended UV-Q/B/Quartz: Aggressive weathering for aerospace or under-hood components

3. Water & Humidity Stress Testing

- Deionised water spray (<0.2 S, <0.1 ppm silica)

- Dual-direction spray (front and back)

- Relative humidity control

4. Temperature Control: BP & CAT

- Black Panel Temperature (BPT): 25 C to 105 C

- Chamber Air Temperature (CAT): Maintains internal environment consistency

- Dual BP/IBP sensors: Ensure precision and ISO/SAE complian

Test Standards Supported by Xenon Arc Weathering Chamber

Automotive and polymer weathering standards supported:-

Automotive Plastics: ASTM D7869, SAE J2412 / J2527, ISO 105-B06/B10, JASO M346/M351

General Plastics: ISO 4892-2, ASTM D2565, ASTM D4459

Coatings: ASTM D6695, ISO 16474-2

Others: MIL-STD-810H, IEC 60068-2-

Correlation with Outdoor Performance

Benchmarking via real-world environments like Florida and Arizona helps ensure long-term polymer stability.

Combined with xenon arc data, this forms a strong basis for predicting durability

Masterbatches Validated Under Xenon Arc Weathering Chamber

- Exterior Body Panels: UV stabilizers, anti-yellowing pigments

- Interior Trims: Color fastness under filtered sunlight

- Under-the-hood Parts: Heat-aging resistance, gloss retention

- Optical Plastics: Haze control, IR resistance

- Silver/Effect Pigments: Gloss & texture retention

- Bumpers & Wheel Arches: Cracking & embrittlement resistance

Value for Industry Decision-Makers

Why It Matters for Procurement & R&D Heads:-

Reduce Field Failures: Pre-qualify materials for lifetime performance

Accelerated Time-to-Market: From years to weeks

Meet Global OEM Norms: Support PPAP, APQP

Data-Backed Formulation Selection: Optimize pigment/resin/additive ratios

Partner With Bajaj Plast

Xenon Arc Weathering Testing ensures each automotive-grade masterbatch is:

- Formulated for UV and thermal resistance.

- Validated using ASTM, ISO, SAE standards

- Ready for performance in any climate zon

Bajaj Masterbatches for Automotive Polymer

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.