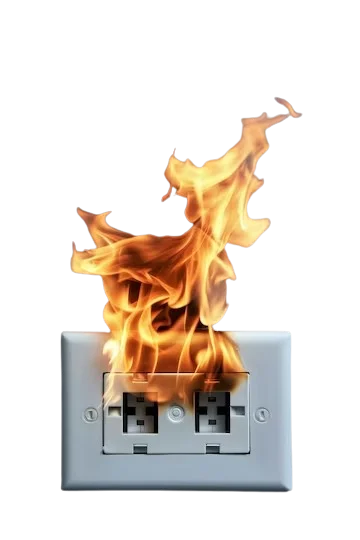

Flame Retardant Additive Masterbatch

Flame Retardant masterbatches are used to prevent the detonation or spread of flame in different plastic materials

For a fire to begin, fuel, oxygen, and a source of ignition must be present. Flame retardants work by interfering with one or more of these fundamentals, either physically or chemically. Flame retardant chemistry ensures end products slow the rate of fire and decrease the generation of burn and smoke. This unique technology is created in order to achieve precise performance standards in accordance with strict fire safety regulations, without affecting other properties. Bajaj flame retardant masterbatches are specially formulated to be effective against fire initiation and dissemination while maintaining the balance and the mechanical properties of plastic products.

Key benefits of Flame Retardants Masterbatch

Other than making plastic products resilient to fire, Bajaj Flame Retardant Masterbatch provided a few more important benefits for plastic manufacturers across different industries. Here are some of the key benefits of Flame Retardant Masterbatches:

Safe for continuous use

Combining Bajaj Flame Retardant Masterbatch with plastic products will assure top safety and extend the product’s durability. The masterbatch will make the products safe for continuous use while maintaining their properties such as colour, strength, and more.

In line with environmental requirements

Bajaj Flame Retardant Masterbatch is manufactured according to strict fire regulations. By mixing it in the batch, the products become safer and of better overall quality, maintaining the legal fire requirements.

Meeting the most rigorous standards

Bajaj Flame Retardant Masterbatch is manufactured according to strict fire regulations. By mixing it in the batch, the products become safer and of better overall quality, maintaining the legal fire requirements.

UL94 flammability test includes the following 4 methods:

UL 94 is a safety standard to determine the flammability of plastic materials. This test is released by Underwriters Laboratories of the United States. It measures:• The ability of the plastic part to extinguish or spread the flame after ignition. • Its dripping behavior in response to a small open flame or radiant heat source under controlled laboratory conditions.This test is a preliminary sign to check the flammability of plastics used in any application. For example, plastic parts used in electronic devices and appliances.

- . Horizontal burning test for UL94 HB rated materials;

- Vertical burning test for UL94 V-0, V-1, and V-2 rated materials;

- Vertical burning test for UL94 5V rated materials;

- Vertical burning test for UL94 VTM-0, VTM-1 and VTM-2 rated materials.

Standard Procedure

UL94 HB Specimen: 5″ × 1/2″ × thickness (typical thickness = 1/16″, 1/8″, 1/4″)

Three specimens of each thickness are to be tested. Before the test, the specimens are placed under 20°C & 50% RH conditions for 48 hours, parallel to the long axis and at a 45° angle to the short axis. For each specimen, draw two lines respectively 1″ and 4″ long from one end, place a 1″ high blue flame at the end of the specimen that is suspended in the air, burn it for 30 seconds and then remove the flame. If the specimen continues to burn after the flame is removed, measure the burning time of the specimen between the two width marks, and burn rate is calculated by inches per minute.

Rating Requirements: 94HB

- A: For specimens with a thickness between 0.120″ and 0.500″, the burn rate cannot exceed 1.5″ per minute, i.e., spanning greater than 3.0″, or

- B: For specimens with a thickness of 0.120″, the span cannot exceed 3.0″, or

- C: Before the flame reaches the 4.0″ mark, the specimen ignites spontaneously. UL94 V-0 / V-1 / V-2

Procedure:

Specimen: 5″ × 1/2″ × thickness (typical thickness = 1/16″, 1/8″, 1/4″)

A total of 10 specimens (2 sets) are tested for each thickness. 5 specimens of each thickness are tested after being placed under 23°C and 50% RH conditions for 48 hours. 5 specimens of each thickness are tested again after being placed under 70°C conditions for 7 days. The specimen is placed and installed perpendicular to the long axis. When installing, keep the lower end of the specimen 3/8″ away from the top of the combustion tube. Place a 3/4″ high blue flame at the center of the lower end of the specimen and burn for 10 seconds. If the specimen drips drop by drop, the liquid will fall on the layer of unsurgically treated cotton placed 12″ below the specimen.

Rating Requirements: 94 V–0

- A: No specimen burns with flame for more than 10 seconds after the test flame is removed;

- B: For each set of 5 specimens, after 10 ignitions, the total time of burning with flame does not exceed 50 seconds;

- C: No specimen burns with flame spreading to the fixture;

- No specimen produces flaming dripping that ignites the cotton located 12″ below;

- E: No specimen continues to burn with glowing combustion for more than 30 seconds after the 2nd removal of the test flame.

Flame ratings to classify plastics

The UL standard classifies plastics according to the minimum thickness at which it stops burning when tested in a horizontal or vertical orientation. The flame ratings covered under these orientations include:Vertical burning tests (V-0, V-1, V-2, 5V, 5VA, 5VB, VTM-0, VTM-1, VTM-2)

Horizontal burning tests (HB, HBF, HF-1, HF-2)

Rating Requirements: 94 V–1

- A: No specimen burns with flame for more than 30 seconds after the test flame is removed;

- B: For each set of 5 specimens, after 10 ignitions, the total time of burning with flame does not exceed 250 seconds;

- C: No specimen burns with flame spreading to the fixture (including flaming and glowing combustion);

- D: No specimen produces flaming dripping that ignites the cotton located 12″ below;

- E: No specimen continues to burn with glowing combustion for more than 60 seconds after the 2nd removal of the test flame.

Applications

Ready To Use Plast Flame Retardant Masterbatch in Your polymer?

Get in touch with us. Connect with Bajaj Plast Executive