Plast Color

High

Performance

Quality

Masterbatch

High Chromatic Strength

Reducing Additive Costs

Without Sacrificing Quality

Of Lightfast Applications

with Minimal Loading

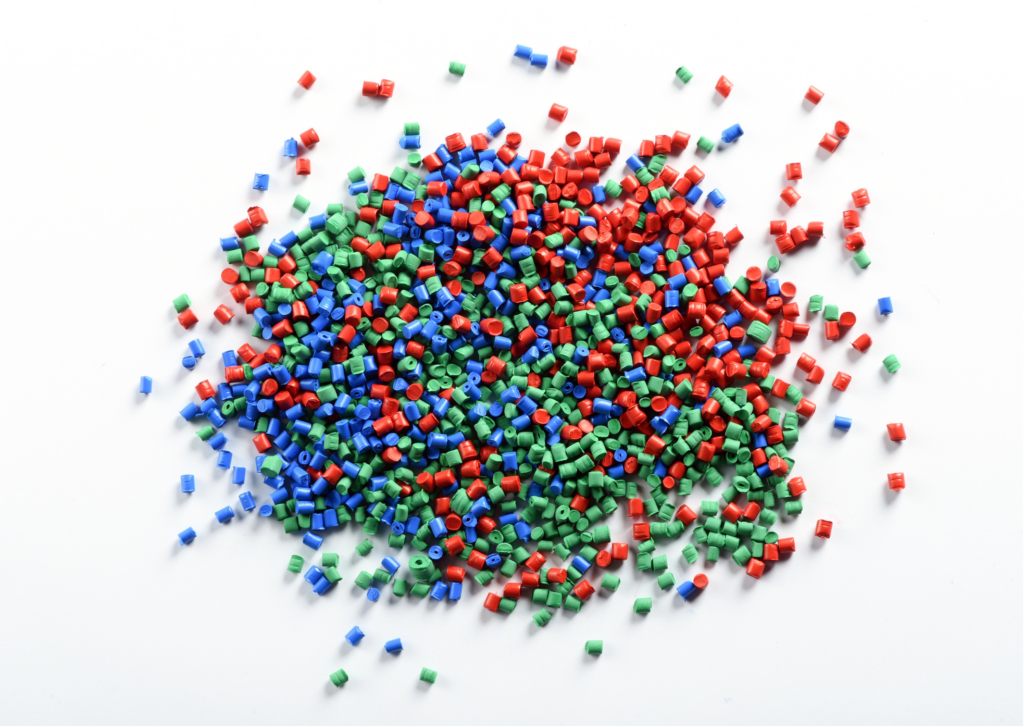

Color Masterbatches

Plast Colour Masterbatches are engineered with cutting-edge pigment dispersion techniques and high-performance carrier systems to ensure uniform colouration, exceptional thermal stability, and optimised polymer compatibility.

Designed for high-throughput processing environments, our formulations meet the stringent demands of injection molding, blow molding, extrusion, roto-molding, and film blowing applications.

We provide customised and standard colour masterbatches developed using spectral colourimetry and calibrated against international standards such as RAL, Pantone, and NCS.

Let’s Talk Color Performance

Whether you’re developing high-gloss consumer goods or UV-stable outdoor components, our technical team collaborates with your R&D and procurement departments to deliver high-performance color masterbatch solutions optimized for your application, equipment, and throughput requirements.

At the core of advanced polymer coloration, our Color Masterbatches offer high-performance pigment and additive formulations engineered for dimensional stability, UV resistance, and batch-to-batch color reproducibility.

Developed to meet the stringent demands of injection molding, blow molding, film extrusion, fiber spinning, and sheet extrusion, our masterbatches deliver unmatched dispersion and process compatibility across a wide spectrum of base resins.

Color Matching to ΔE ≤ 1

DELTA

Our in-house color laboratory, equipped with X-Rite® spectrophotometers and twin-screw compounding extruders, provides rapid prototyping and scalable color development tailored to your polymer matrix and end-use conditions. Submit your resin type, processing method, and desired shade, and our color engineers will match it with <1 ΔE variance tolerance.

Utilizing spectrophotometric analysis and Delta E tolerance systems, our in-house color labs deliver exact matches to international standards (Pantone®, RAL®, NCS®, etc.) or customer-submitted samples

From opaque to transparent, pastel to high chroma hues, our solutions deliver exceptional color consistency (ΔE ≤ 1.0) even under high-shear, high-temperature processing conditions.

Up to 60%

High Pigment Loading

Organic, inorganic, and hybrid pigment systems with superior lightfastness and weatherability.Pigment concentrations up to 60% for maximum tinting strength with minimal let-down ratios.Formulated to withstand processing temperatures up to 330°C without degradation or discoloration.

Ensures maximum opacity, vibrancy, and tint strength with minimal let-down ratios, enhancing cost-efficiency during production.Achieves uniform distribution of pigments and additives, avoiding die streaking, spotting, or gel formation in high-throughput lines.

1–4%

Let-down Ratio(LDR)

A minimal let-down ratio (LDR) in color masterbatches indicates high pigment concentration and dispersion efficiency, allowing less masterbatch to be used per unit of base polymer—often as low as 1% (100:1). This enhances color strength, reduces material costs, and optimizes storage, logistics, and processing efficiency

A low LDR improves melt flow compatibility, minimizes defects like streaking or die build-up, and ensures consistent coloration across production runs. It also supports sustainability by lowering overall additive usage and enhancing recyclability.

Minimal LDR masterbatches are ideal for applications requiring precise, high-performance pigmentation in film, injection molding, and fiber.

Additive Integration

UV stabilizers, antioxidants, anti-static agents, and optical brighteners optionally integrated for multifunctional performance.Pigments and additives are thermally stable to withstand high processing temperatures.Prevents discoloration, degradation, and blooming during extrusion or injection molding.High UV resistance Additives to maintain color strength and shade under prolonged exposure to sunlight and outdoor environments.

Delivering Consistent Chromatic Integrity

Consistency

Consistent batch-to-batch accuracy is achieved through in-line spectrophotometry and closed-loop QC systems.

Low Dust

Free-Flowing Granules for reduced hopper clogging and better machine hygiene.

Fast Lead Times

Just-in-time manufacturing enabled by lean supply chain and modular compounding lines.

Compliance

FDA, RoHS, REACH, and ISO 9001:2015 certified manufacturing.