Why Moisture Causes Bubbles in Recycled Plastic & How Desiccant Masterbatch Helps

In the recycled plastic industry, moisture contamination is one of the most underestimated causes of processing defects. For B2B manufacturers, purchase managers, and plant operators, moisture-related issues directly impact product quality, machine efficiency, rejection rates, and profitability.

One of the most visible and costly problems? Bubbles, voids, and surface defects in recycled plastic products.

This blog explains:

Why moisture causes bubbles in recycled plastic

The technical mechanism behind vapor formation

How desiccant masterbatch works at a molecular level

How to select the right desiccant masterbatch for industrial applications

Understanding the Moisture Problem in Recycled Plastic

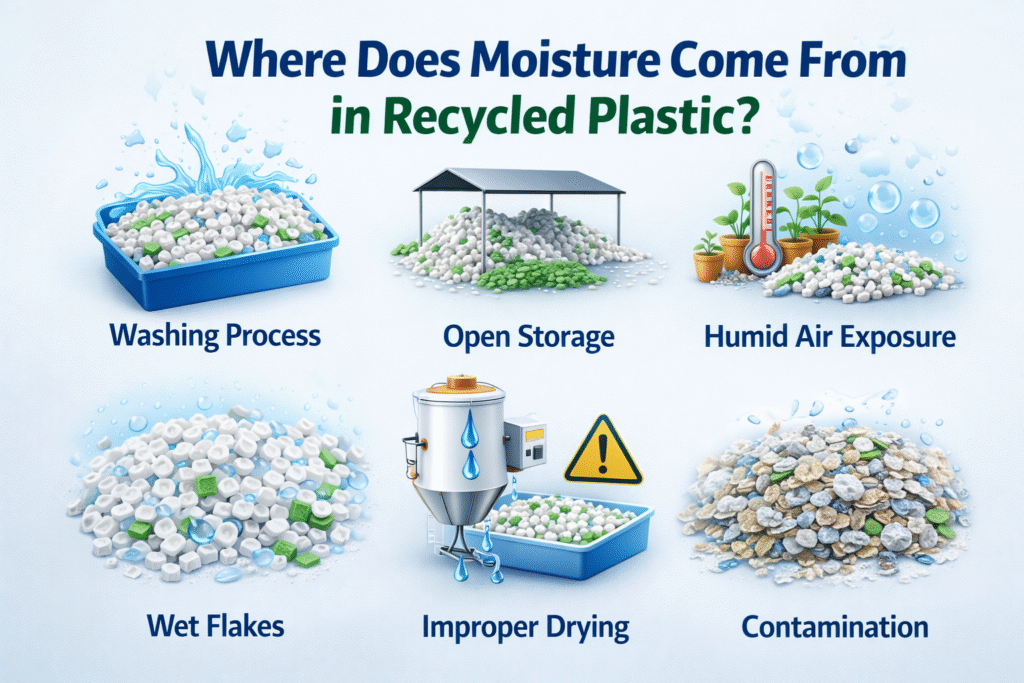

Unlike virgin polymers, recycled plastic contains higher moisture levels due to:

Washing processes during recycling

Open-air storage of flakes or granules

Hygroscopic polymer structures

Contaminated scrap streams

Improper drying before extrusion

Common moisture-affected polymers:

Recycled LDPE / LLDPE

Reprocessed HDPE

Recycled PP raffia & woven sack material

PET regrind

Multilayer recycled blends

Even 0.1%–0.3% moisture content can cause severe defects during extrusion or molding.

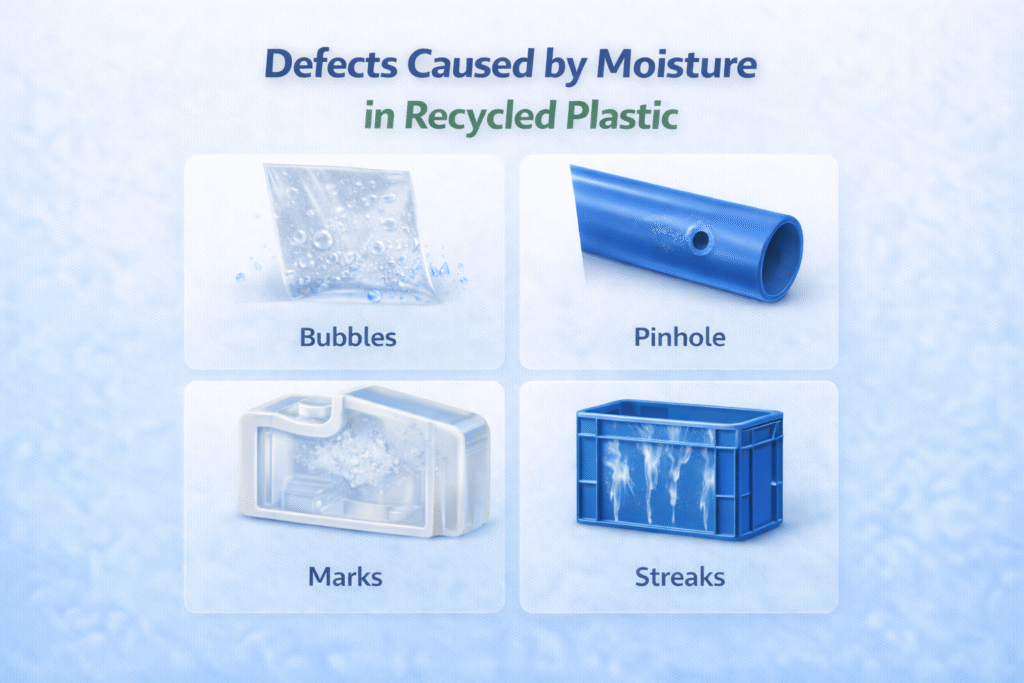

How Moisture Causes Bubbles in Recycled Plastic

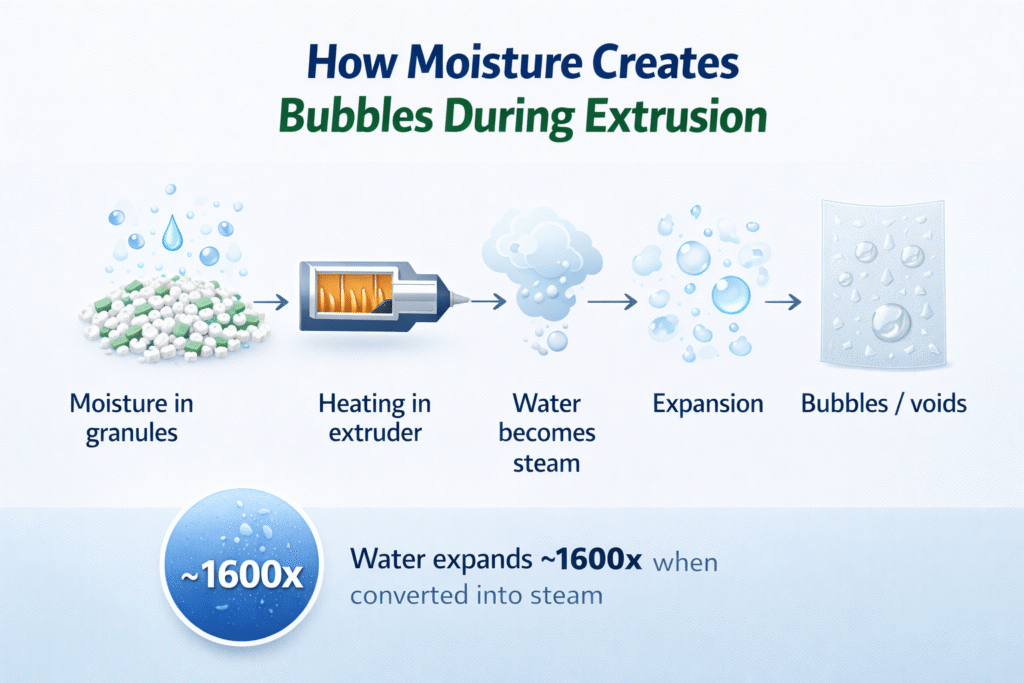

When recycled plastic is processed in an extruder or molding machine, temperatures typically range between 160°C to 280°C, depending on the polymer.

At these temperatures:

1.Water Converts into Steam

Moisture trapped inside the polymer matrix rapidly vaporizes.

Water expands nearly 1600 times in volume when converted into steam.

This expansion creates:

Micro-voids

Internal bubbles

Surface blistering

Pinholes in films

Silver streaking in molded parts

2.Hydrolytic Degradation (In Hygroscopic Polymers)

For polymers like PET, Nylon, and some recycled engineering plastics:

Moisture causes hydrolysis, breaking polymer chains.

Result:

Reduced molecular weight

Lower tensile strength

Brittleness

Poor elongation

Reduced impact resistance

This is a major concern for B2B buyers supplying automotive, packaging, or infrastructure sectors.

3.Processing Instability

Moisture leads to:

Melt fracture

Unstable melt pressure

Irregular bubble formation in blown film

Die drool

Poor surface finish

Inconsistent thickness

For purchase managers, this translates to:

Higher rejection rates

Increased machine downtime

Increased energy cost

Customer complaints

Why Traditional Drying Is Not Always Enough

Many recyclers rely on:

Hot air drying

Hopper dryers

Sun drying

Inline drying systems

However, in recycled plastics:

Moisture is often chemically trapped

Contaminants hold water internally

Irregular flake sizes prevent uniform drying

High ambient humidity reintroduces moisture

This is where Desiccant Masterbatch becomes critical.

What is Desiccant Masterbatch?

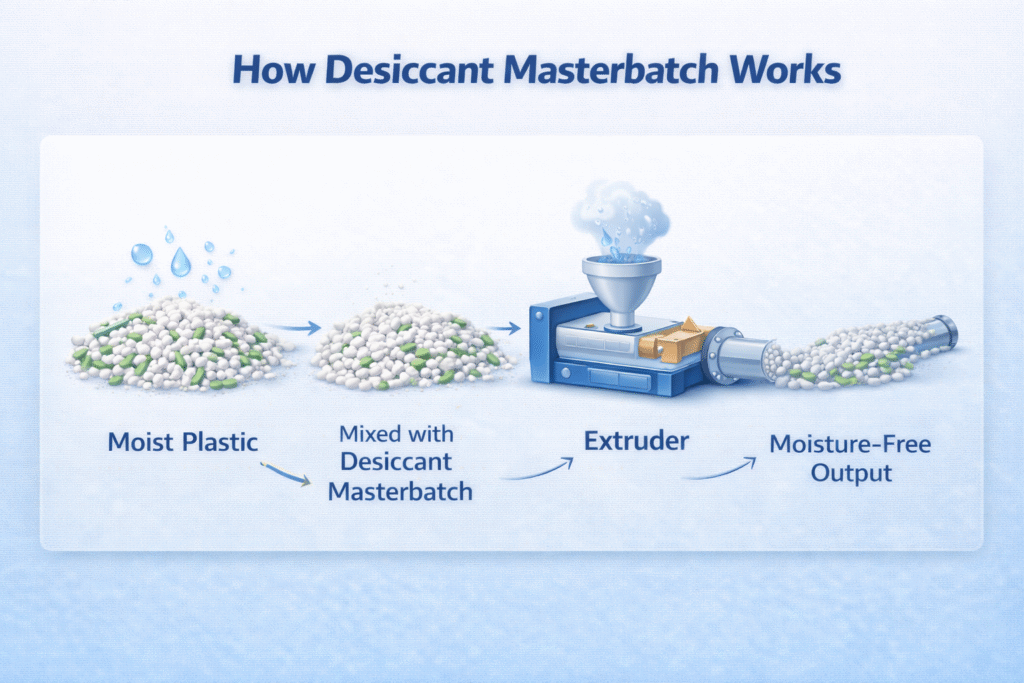

Desiccant Masterbatch is a specially formulated additive masterbatch designed to absorb and neutralize moisture during processing.

It is typically composed of:

High-efficiency moisture absorbers (e.g., calcium oxide-based compounds)

Carrier resin compatible with base polymer

Processing stabilizers

- It is added directly into the extruder along with recycled plastic.

How Desiccant Masterbatch Works (Technical Mechanism)

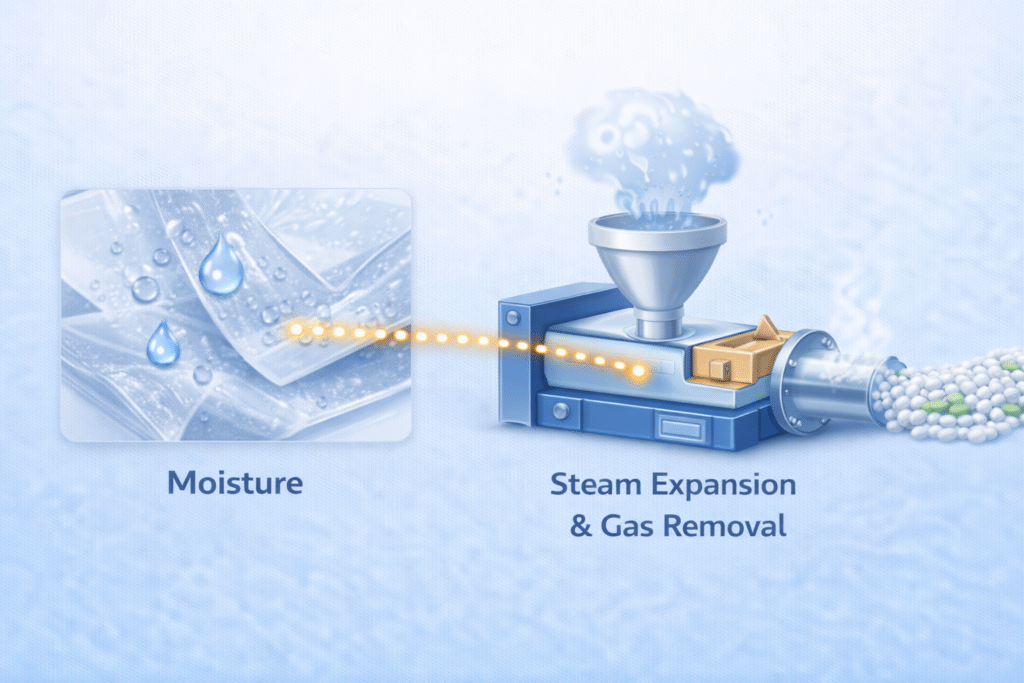

The working principle involves a chemical absorption reaction, not just physical adsorption.

Step 1: Moisture Activation

At processing temperatures, trapped moisture is released inside the melt.

Step 2: Chemical Reaction

Desiccant particles react with water molecules to form stable hydroxides.

Example reaction:

CaO + H₂O → Ca(OH)₂

This reaction:

Prevents steam formation

Eliminates vapor expansion

Stops bubble formation

Step 3: Stable Dispersion

The reaction byproduct remains finely dispersed within the polymer matrix without affecting surface finish when used at recommended dosages.

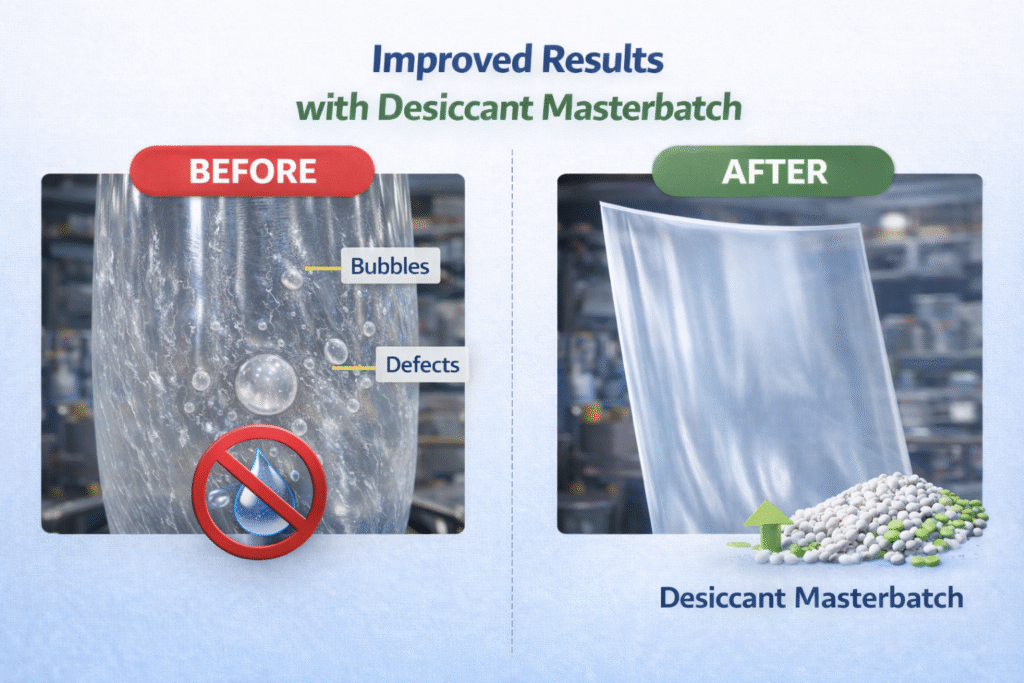

Benefits of Using Desiccant Masterbatch in Recycled Plastic

For B2B manufacturers and procurement teams, the advantages are measurable:

Eliminates Surface Bubbles & Voids

Ensures smooth finish in:

Blown films

Carry bags

Drip irrigation pipes

Molded crates

Garbage bags

Improves Mechanical Strength

Prevents hydrolytic degradation in moisture-sensitive polymers.

Reduces Rejection Rates

Lower scrap generation = higher profitability.

Improves Process Stability

Stable melt pressure

Better bubble stability in blown film

Reduced die build-up

Cost-Effective Alternative to Advanced Drying Systems

Reduces dependency on:

High-energy dryers

Pre-drying equipment

Long drying cycles

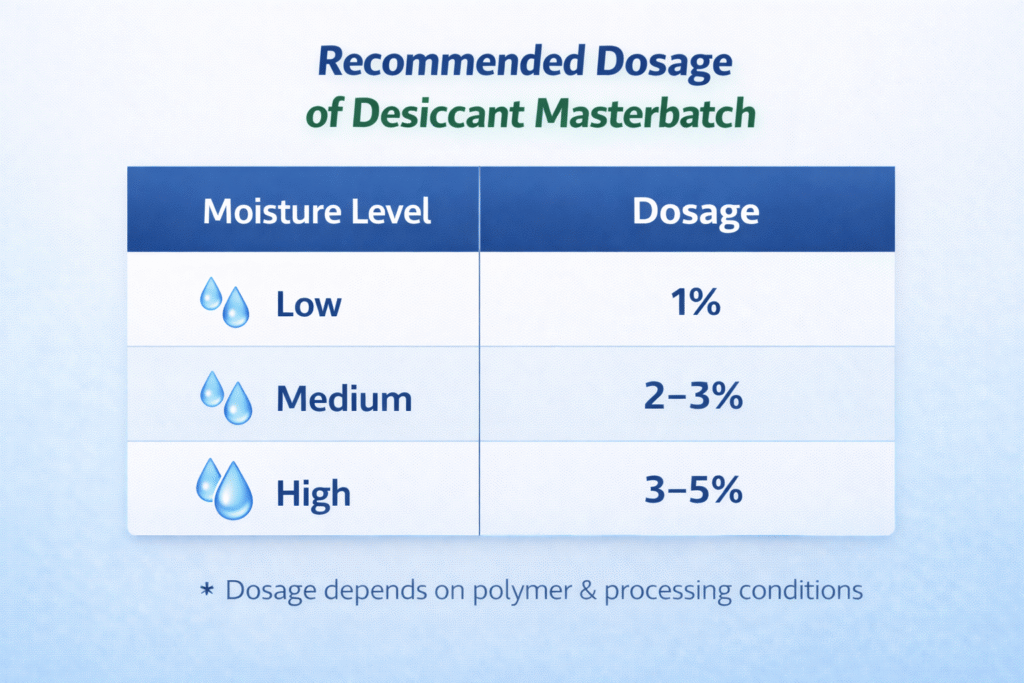

Recommended Dosage for Industrial Use

Typical dosage range:

1% to 3% for moderate moisture levels

3% to 5% for high moisture recycled content

Exact dosage depends on:

Polymer type

Moisture level

End application

Processing temperature

For B2B purchase managers, requesting a technical trial sample before bulk procurement is recommended.

Applications Where Desiccant Masterbatch is Essential

Recycled LDPE film manufacturing

Garbage bags production

Multilayer recycled films

Injection molded recycled crates

Agricultural pipes

Woven sacks (PP raffia)

Recycling plants using high regrind ratios

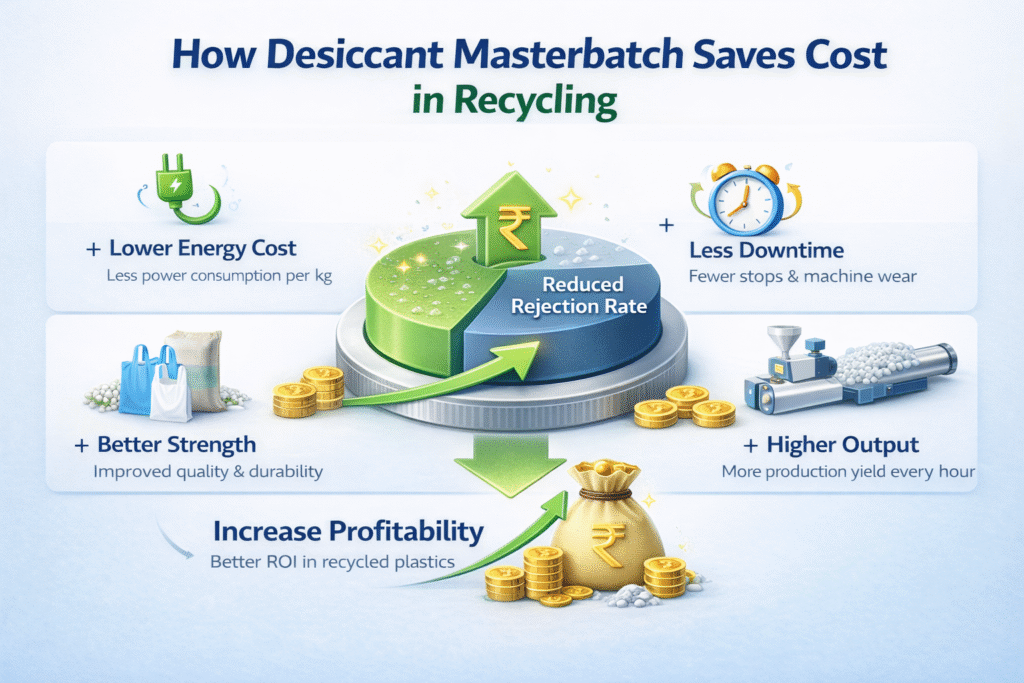

ROI Perspective for Purchase Managers

Let’s quantify the impact:

Without desiccant masterbatch:

5%–8% rejection due to bubbles

Increased power consumption

Machine downtime

Customer return claims

With proper dosage:

Rejection reduces to <1%

Higher production output

Improved customer satisfaction

Lower operational cost per kg

Even a 1% reduction in rejection in a 1000 MT/month plant can generate significant savings.

How to Select the Right Desiccant Masterbatch Supplier

When sourcing desiccant masterbatch, evaluate:

Absorption efficiency (lab-tested data)

Compatibility with LDPE/HDPE/PP

Dispersion quality

Ash content

Effect on mechanical properties

Long-term storage stability

Consistent particle size

Avoid low-quality desiccants that:

Increase brittleness

Cause black specks

Increase die pressure

Affect transparency

Conclusion

Moisture in recycled plastic is not just a minor processing issue — it is a profitability risk for manufacturers.

Bubbles, voids, and hydrolytic degradation directly impact:

Product quality

Customer trust

Production efficiency

Operational margins

A high-quality Desiccant Masterbatch for recycled plastic acts as an in-process moisture neutralizer, ensuring stable extrusion, superior surface finish, and consistent mechanical properties.

For B2B manufacturers and purchase managers, it is not an expense — it is a process optimization tool that safeguards production efficiency and brand reputation.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.