Quality Complaints in Masterbatch: Root Cause Analysis and Prevention Strategies

In the plastics value chain, masterbatch quality complaints are more than a routine operational issue—they directly impact production efficiency, final product aesthetics, mechanical performance, and brand reputation.

For B2B buyers, procurement heads, and plant managers, understanding why these complaints arise and how to prevent them is critical to controlling costs and ensuring consistent output.

This blog dives deep into the technical root causes of masterbatch quality complaints and outlines proven prevention strategies used by high-performing manufacturers.

Why Quality Complaints in Masterbatch Matter

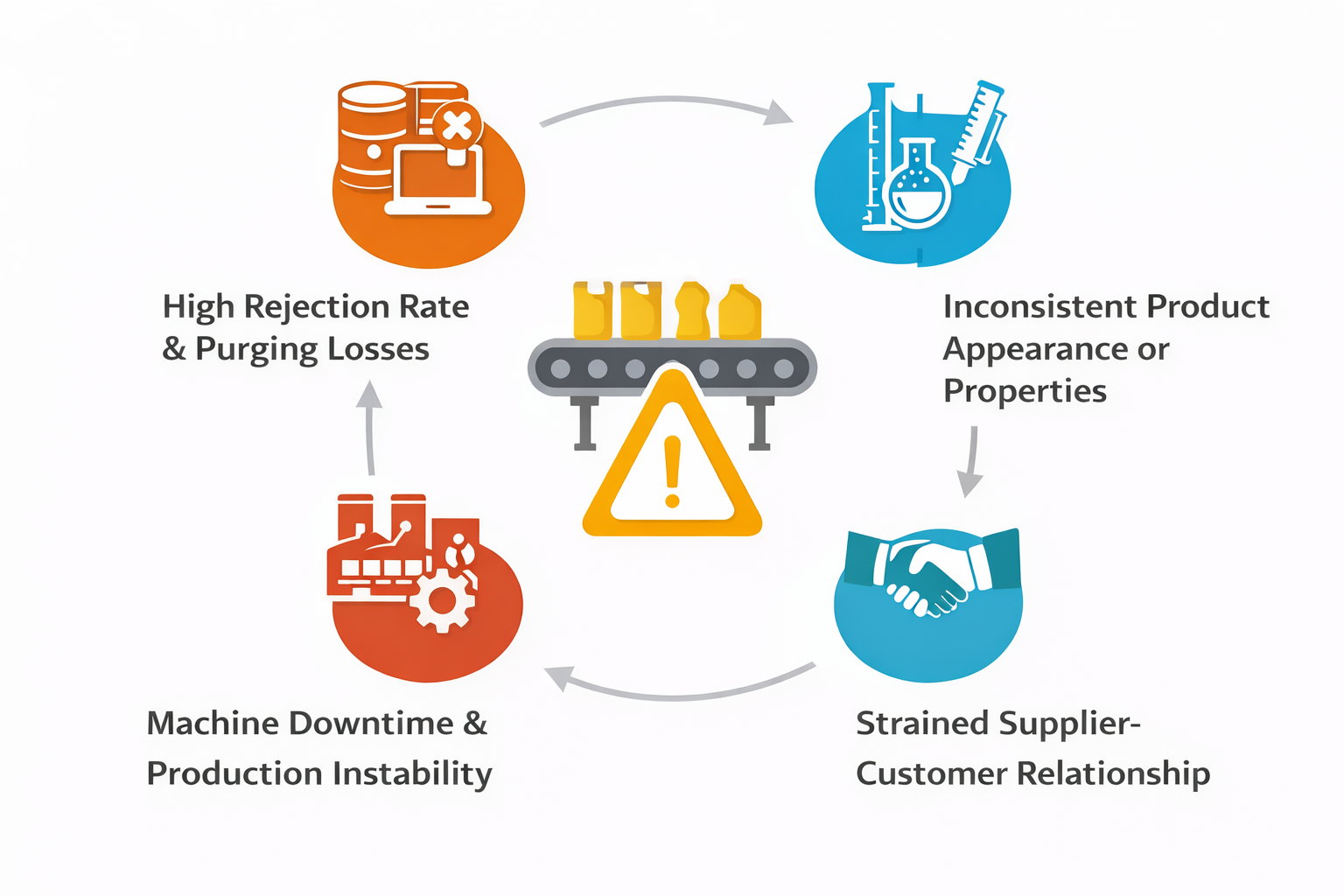

A single batch of defective masterbatch can lead to:

High rejection rates at the processor’s end

Machine downtime and purging losses

Inconsistent product appearance or properties

Strained supplier–customer relationships

From an industry standpoint, “masterbatch quality issues” and “masterbatch complaints” are rising concerns as processors demand higher precision, lower tolerance variation, and application-specific performance.

Common Quality Complaints in Masterbatch

1. Color Variation and Shade Inconsistency

Complaint:

Finished plastic parts show shade mismatch, streaks, or patchiness.

Root Causes:

Poor pigment dispersion due to inadequate shear during compounding

Incorrect pigment-to-carrier compatibility

Batch-to-batch variation in pigment strength

Inconsistent let-down ratios at customer end

Technical Insight:

Even minor variations in pigment particle size distribution can cause visible ΔE shifts in sensitive applications like packaging films, molded containers, or automotive parts.

2. Poor Dispersion and Speck Formation

Complaint:

Black spots, white specks, or unmelted particles in finished products.

Root Causes:

Inadequate melt mixing in twin-screw extruders

Overloaded screw configuration for high pigment loading

Agglomerated fillers or additives

Improper cooling and pellet cutting

Technical Insight:

Specks not only affect aesthetics but also act as stress concentrators, reducing mechanical strength.

3. Low Mechanical Performance of End Product

Complaint:

Reduced tensile strength, elongation, or impact resistance.

Root Causes:

Excessive filler loading to reduce cost

Incompatible carrier resin

Thermal degradation during masterbatch processing

Poor additive dispersion affecting polymer matrix integrity

Key Point for Buyers:

A cheaper masterbatch often results in hidden costs due to downgraded physical properties of the final plastic product.

4. Processing Issues: Die Build-Up, Screw Slippage, Smoke

Complaint:

Poor machine runnability at customer processing lines.

Root Causes:

Incorrect selection of processing aids

Low thermal stability polymer

Contamination or moisture presence

Carrier resin mismatch with base polymer

Technical Insight:

processing problems caused by masterbatch

5. Moisture-Related Defects

Complaint:

Bubbles, silver streaks, surface defects.

Root Causes:

Hygroscopic fillers not dried properly

Poor packaging and storage conditions

Inadequate moisture control during production

6. Inconsistent Pellet Size or Pellet Breakage

Complaint:

Feeding problems and uneven dosing.

Root Causes:

Improper strand cutting

Uneven cooling

Poor pelletizer maintenance

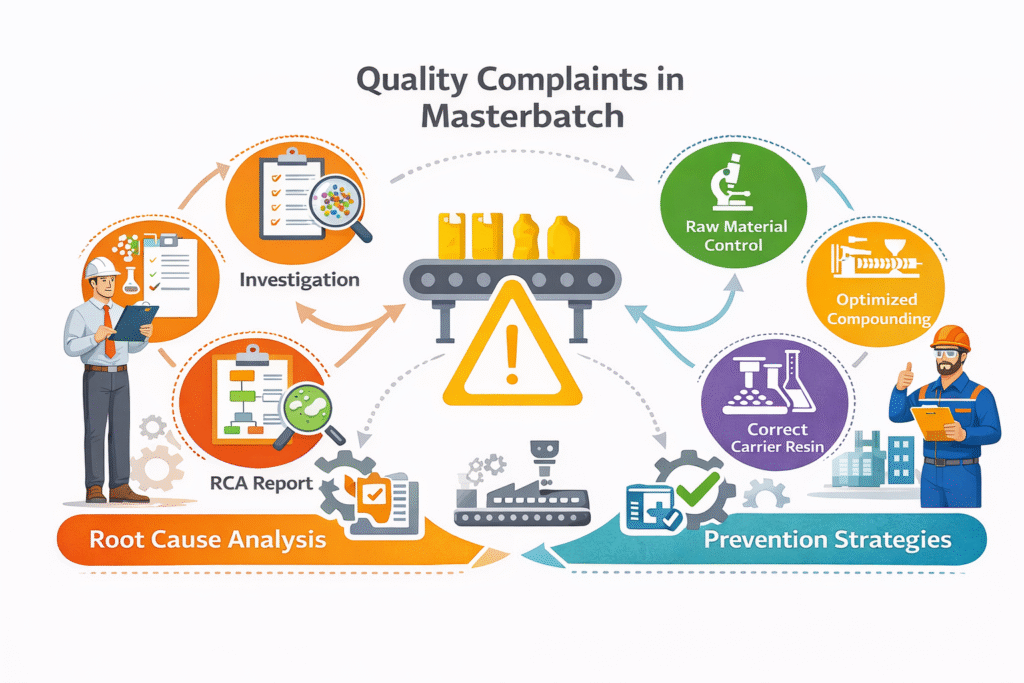

Root Cause Analysis (RCA): A Structured Approach

Leading masterbatch manufacturers follow a data-driven RCA framework, including:

Incoming raw material validation

In-process monitoring (torque, melt pressure, temperature)

Batch traceability and retention samples

End-use simulation testing

For buyers, suppliers who document RCA reports demonstrate maturity and reliability.

Root Cause Analysis (RCA): A Structured Approach

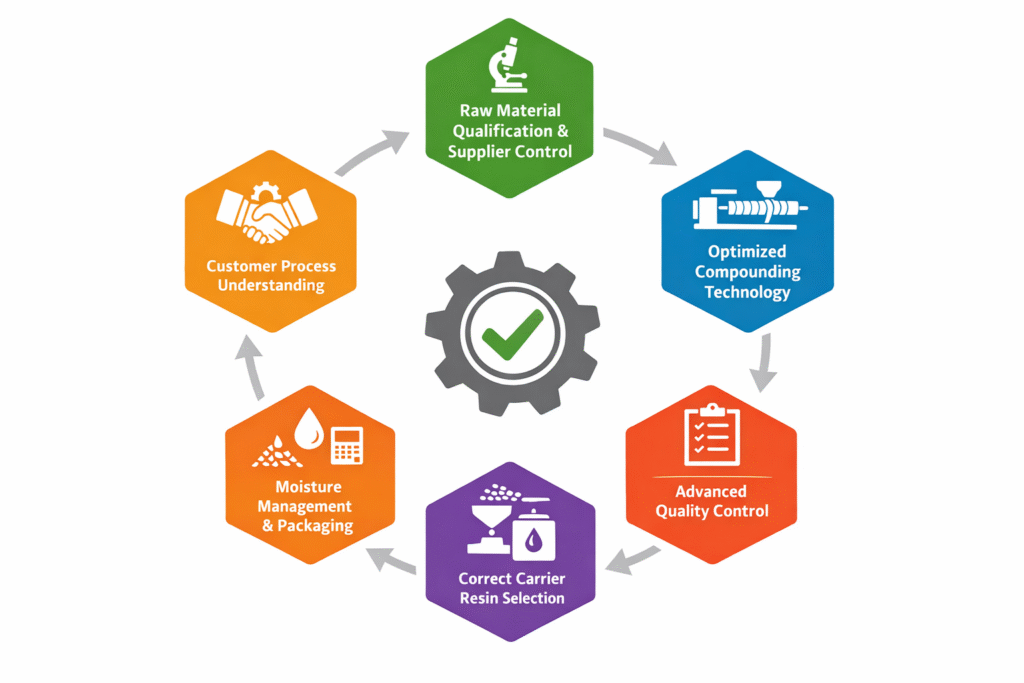

1. Raw Material Qualification & Supplier Control

Use consistent-grade pigments and additives

Conduct incoming QC: particle size, moisture, bulk density

Avoid frequent raw material substitutions without validation

2. Optimized Compounding Technology

Application-specific screw design

Controlled shear to balance dispersion without degradation

Gravimetric dosing for accuracy

3. Advanced Quality Control Systems

Spectrophotometer-based color control

MFI, ash content, dispersion testing

Retention samples for traceability

Tip for Buyers: Ask for COA + batch-wise QC data.

4. Correct Carrier Resin Selection

Carrier resin must match:

Base polymer (PP, PE etc.)

Processing temperature window

End-use regulatory requirements

Mismatch is one of the most underestimated causes of complaints.

5. Moisture Management & Packaging

Use dehumidified dryers

Moisture barrier packaging

Clear storage and shelf-life guidelines

6. Customer Process Understanding

Top-tier suppliers:

Study customer processing conditions

Recommend optimal let-down ratios

Offer trial support and troubleshooting

This transforms suppliers from vendors into technical partners.

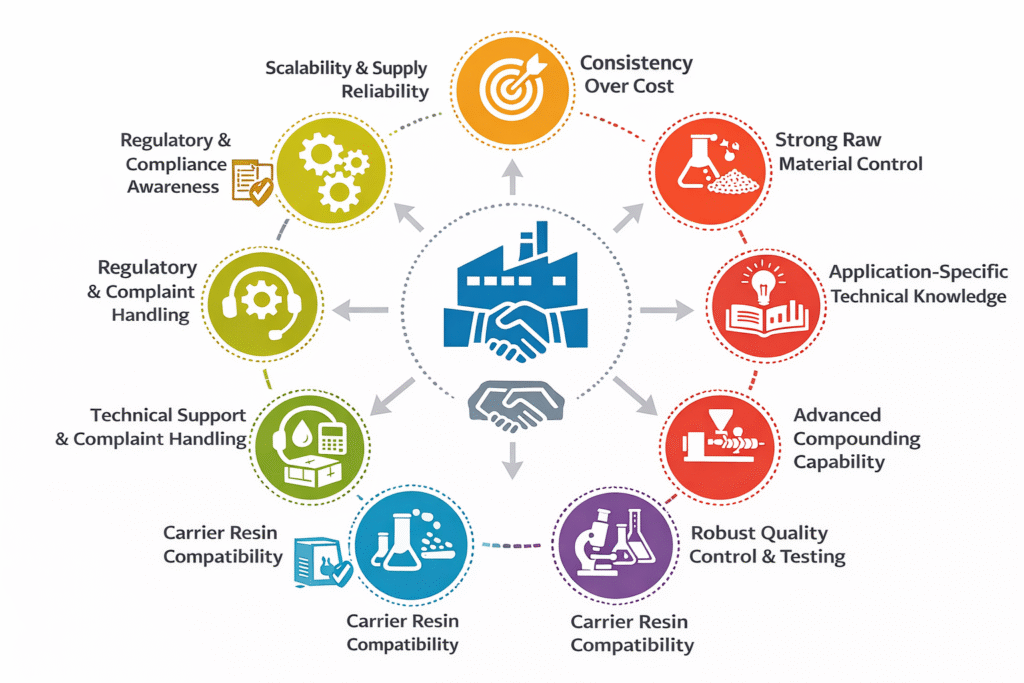

What B2B Buyers Should Look for in a Masterbatch Supplier

Before finalizing a supplier, evaluate:

Process capability, not just pricing

Consistency across multiple batches

Technical support responsiveness

Customization capability for applications

Remember: A reliable masterbatch supplier reduces your production risk.

Final Thoughts

Quality complaints in masterbatch are rarely random—they are the result of systemic gaps in raw material control, process design, or application understanding.

For B2B buyers and decision-makers, selecting the right masterbatch partner is a strategic decision, not a procurement formality.

By focusing on root cause analysis and preventive systems, both manufacturers and buyers can achieve:

Lower rejection rates

Stable production

Superior end-product performance

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.