HALS 770 UV Stabilizer – Premium Hindered Amine Light Stabilizer for Plastics

Ultraviolet (UV) radiation is one of the most damaging environmental factors affecting plastic materials. Continuous UV exposure leads to polymer degradation, resulting in discoloration, loss of mechanical strength, brittleness, cracking, and surface chalking.

To overcome these challenges, manufacturers use advanced light stabilizers such as HALS 770.

HALS 770 (Hindered Amine Light Stabilizer 770) is a high-performance, non-yellowing UV stabilizer designed to deliver long-term weather resistance and enhanced durability in polymers.

What is HALS 770?

HALS 770 is a premium Hindered Amine Light Stabilizer (HALS) that protects plastics from UV-induced oxidation and polymer breakdown. It is widely used in outdoor applications where long-term stability and durability are required.

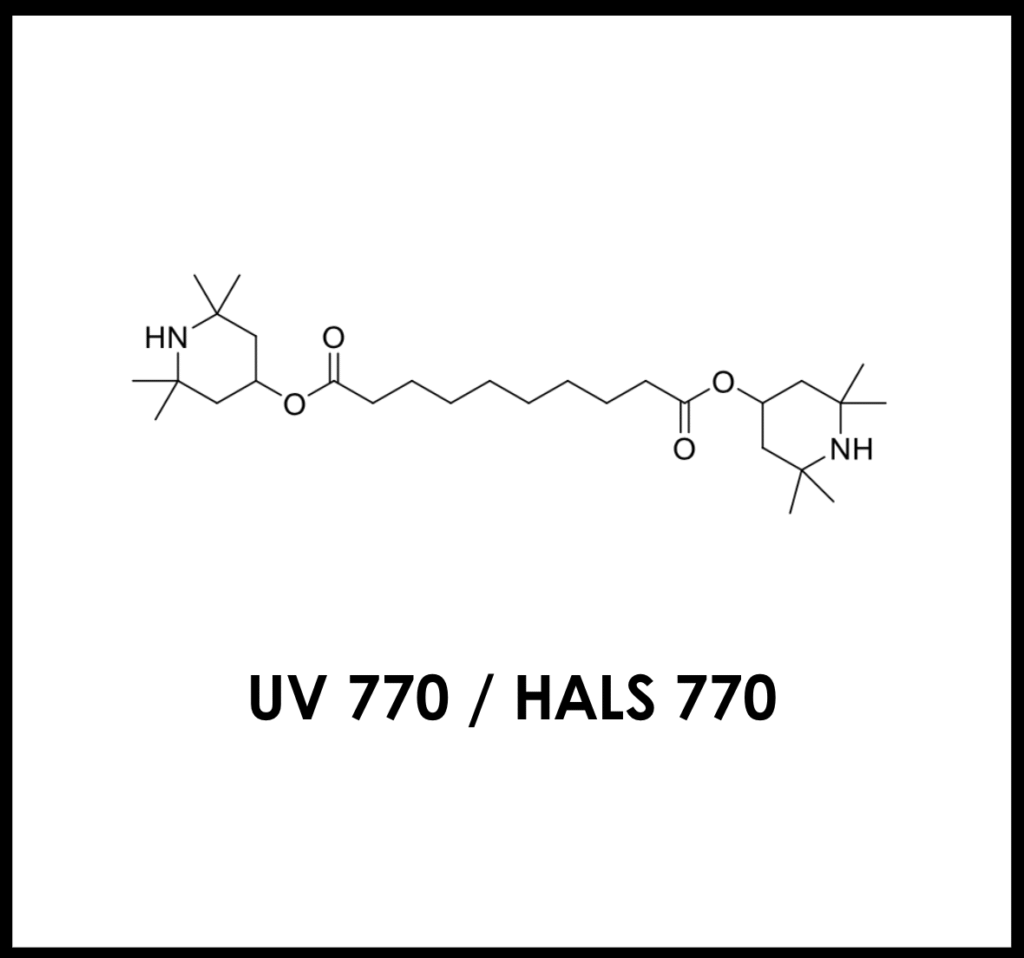

HALS 770 is mainly composed of:

HALS 770 is mainly composed of:

Poly[[6-[(1,1,3,3-tetramethylbutyl)amino]-s-triazine-2,4-diyl][(2,2,6,6-tetramethyl-4-piperidinyl)imino]-1,6-hexanediyl[(2,2,6,6-tetramethyl-4-piperidinyl)imino]]

Its chemical structure provides excellent resistance to UV radiation, ensuring long-term polymer performance even in harsh environments.

How Does HALS 770 Work in UV Stabilization?

HALS 770 works differently compared to UV absorbers. Instead of absorbing UV light, it functions through a free radical scavenging mechanism.

When plastic is exposed to sunlight, UV radiation generates free radicals in the polymer structure. These radicals trigger oxidative chain reactions that cause material degradation. HALS 770 prevents this process by:

Neutralizing free radicals

Capturing peroxy radicals

Interrupting photo-oxidative degradation cycles

Regenerating stabilizing activity repeatedly

This cyclic mechanism makes HALS 770 one of the most efficient UV stabilizers for long-term applications.

Key Benefits of HALS 770 UV Stabilizer

HALS 770 offers multiple advantages in polymer stabilization:

1. Superior UV Resistance

Provides long-term protection against UV radiation and prevents polymer deterioration.

2. Non-Yellowing Performance

Its effectiveness across a wide range of materials and industries makes it a highly versatile UV stabilizer.

3. Maintains Mechanical Strength

Helps retain polymer properties such as:

tensile strength

flexibility

impact resistance

surface hardness

4. Prevents Cracking and Brittleness

Minimizes oxidative degradation, reducing surface cracking and brittleness in outdoor plastics.

5. High Efficiency in Thin-Section Applications

HALS 770 performs extremely well in:

thin films

sheets

packaging materials

injection molded thin parts

6. Cost-Effective Lifecycle Protection

By increasing the service life of plastic products, HALS 770 reduces maintenance and replacement costs.

Applications of HALS 770

HALS 770 is widely used across various industries:

Automotive Industry:

bumpers

dashboards

trims

exterior plastic parts

Construction Materials

pipes

roofing sheets

outdoor panels

Packaging Industry:

transparent films

flexible packaging

plastic containers

Agriculture:

greenhouse films

mulch films

irrigation pipes

plastic tapes

Furniture Industry:

plastic chairs

outdoor storage boxes

decorative plastic fixtures

Advantages and limitations of using HALS 770

Advantages of using HALS 770

Superior UV Resistance:

- HALS 770 exhibits excellent UV stabilization, thus preventing discoloration and degradation of materials.

Versatility:

Its effectiveness across a wide range of materials and industries makes it a highly versatile UV stabilizer.

Cost-Effective:

By extending the lifecycle of materials, HALS 770 reduces the frequency of replacements, offering significant cost savings.

Effective in Thin-Section Applications:

Where many UV stabilizers fail, HALS 770 proves its worth by providing adequate protection in thin-section applications.

Limitations of using HALS 770

Temperature Sensitivity:

The effectiveness of HALS 770 may be reduced at high temperatures, limiting its usage in applications exposed to extreme heat.

Incompatibility with Certain Materials:

Not all materials are compatible with HALS 770. Therefore, testing for compatibility is vital before use.

Potential Environmental Impact:

Like many chemical compounds, HALS 770 may pose environmental concerns if not properly managed and disposed of.

Cost:

Despite the long-term cost savings, the initial expense of incorporating HALS 770 can be higher than other UV stabilizers.

How is HALS 770 different from other UV stabilizers?

Comparison with other joint UV stabilizers like HALS 770 vs. HALS 944

| Feature | HALS 770 | HALS 944 |

|---|---|---|

| Molecular Weight | Lower | Higher |

| Best Use | Thin sections | Thick sections |

| Thermal Stability | Moderate | High |

| Migration Resistance | Moderate | Excellent |

| Cost | Premium | Competitive |

HALS 770 is best for thin films and packaging applications, while HALS 944 is preferred for thick molded outdoor products.

Unique features and benefits of HALS 770

HALS 770, as a prominent UV stabilizer, offers unique features and benefits that contribute to its widespread use:

Versatility:

Despite its lower molecular weight, HALS 770’s compatibility with numerous polymers makes it a versatile choice for a range of applications.

Performance in Thin-Section Applications:

It is particularly effective in thin-section applications where its low molecular weight allows for optimal dispersion and protection.

Resistance to Extraction:

Owing to its specific molecular structure, HALS 770 exhibits good resistance to extraction by water and detergents, enhancing its performance in outdoor applications

Light Stability:

HALS 770 offers superior light stability, protecting polymers from the harmful effects of UV radiation, prolonging their lifespan, and maintaining their aesthetic qualities.

Synergy with Other Additives:

HALS 770 shows excellent synergy with other additives, such as antioxidants, providing comprehensive protection to polymers.

The selection of HALS 770 as a UV stabilizer offers distinct advantages, making it a valuable choice for various industries. It is particularly beneficial in applications where superior light stability and resistance to extraction are essential.

Compatibility with different types of polymers

HALS 770 is compatible with a broad range of polymers, enhancing their durability and stability in various environments. Its adaptability with different types of polymers includes, but is not limited to:

Polypropylene (PP)

HALS 770 provides excellent UV protection for PP, which is commonly used in packaging, automotive components, and textiles.

Low-Density Polyethylene (LDPE):

The low molecular weight of HALS 770 allows for optimal dispersion in LDPE, a popular material in plastic bags and containers.

High-Density Polyethylene (HDPE):

- HDPE, often used in heavy-duty applications, benefits from the enhanced light stability offered by HALS 770.

It’s important to note that the effectiveness of HALS 770 can vary depending on the specific polymer and application, and further testing may be required to optimize its use.

Impact of HALS 770 on product durability

Incorporating HALS 770 into your polymer products significantly enhances their durability in several ways:

UV Resistance:

HALS 770 provides adequate protection against harmful UV radiation, preventing discoloration and structural degradation due to prolonged exposure to sunlight.

Thermal Stability:

It resists degradation at a wide range of temperatures, thereby extending the lifespan of products even under harsh conditions.

Improved Color Stability:

The use of HALS 770 helps maintain the original color of the product for a more extended period, resisting fading or yellowing caused by various environmental factors.

Enhanced Mechanical Properties:

By preventing oxidative degradation, HALS 770 maintains the mechanical properties of the polymer, including tensile strength, impact resistance, and flexibility.

Chemical Resistance:

It imparts resistance to various pH levels and chemical environments, further improving the durability and longevity of the product.

Remember, the extent of these benefits may depend on the specific polymer and its application, as well as the concentration of HALS 770 used.

Why is HALS 770 considered a premium light stabilizer?

Enhanced UV Protection Provided by HALS 770

HALS 770 offers superior UV protection by neutralizing free radicals produced during UV absorption, which prevents polymer degradation. Its effectiveness is not diminished over time, providing long-lasting UV resistance that substantially enhances product durability.

Long-term Effects of HALS 770 on Material Degradation

Over the long term, HALS 770 significantly slows down the process of material degradation. It preserves the structural integrity and appearance of polymers, resulting in products that maintain their quality and performance over an extended period.

Testing and Certification Standards for HALS 770

HALS 770 complies with rigorous testing and certification standards that verify its UV resistance, thermal stability, and overall performance. These standards include ISO 4892 (Artificial Weathering), ASTM D4459 (UV Exposure of Plastics), and ASTM D2565 (Xenon-Arc Exposure).

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.