Testing the UV resistance of FIBCs

Big bags are most commonly made of woven polypropylene, a polymer that, like other materials, is damaged by exposure to sunlight over time. This degradation process can ultimately cause the fabric to tear when exposed to strain and put both content and personnel at risk. Fortunately, through the use of UV stabilisers in the polymer and the proper handling of FIBCs, the risk of photochemical damage can be reduced to a minimum. It is, however, vital that FIBCs are covered or stored away from the sunlight during usage, transport and storage.

Standardised tests to demonstrate the UV resistance of FIBC

Standardised tests to demonstrate the UV resistance of FIBC have been in existence since 1989. The UV resistance test according to Annex A of ISO 21898:2004 is currently the prevailing standard. However, standardised test conditions inevitably vary from the real-life conditions that FIBC are exposed to during use. Not only does the spectrum and intensity of UV radiation vary in different climate zones, but also other weather factors like temperature, humidity or frost play a role. Furthermore, substances in contact with the polymer, like pigments and even the goods filled into the FIBC, may also have an influence on the UV stability of the bag.

The combination of these elements will influence the speed of photochemical degradation of the polymer fabric of FIBCs in real life. This has led to voices from the industry questioning how well the laboratory tests set out in ISO 21898:2004 correlate to real-life conditions and can predict the life-time of FIBCs used in different climate zones around the world.

Ultraviolet light is harmful to plastics because it attacks the carbon bonds in the chemical structure, releasing free radicals that in turn react with oxygen in the air, destabilising the plastics’ chemical structure and degrading it.

Improving protection

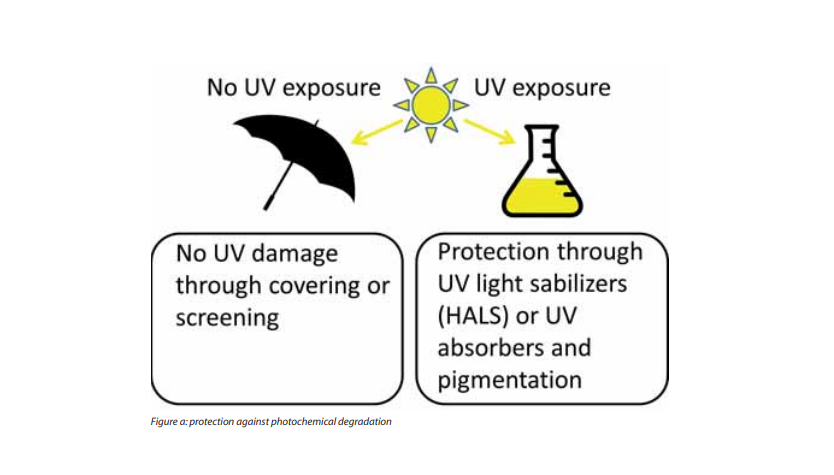

The most obvious way to mitigate the degradation of an FIBC due to UV radiation and other weather impacts is physically to protect the bags from the elements. Although FIBC handling instructions routinely advise against outdoor exposure, this is not always practical for users and certainly not controllable by FIBC producers and traders.

Chemical alternatives are available and widely used to help polymers like polypropylene maintain their properties longer against degradation through environmental influences. To counter the harmful effects of UV light on FIBCs, two main methods are used:

UV light absorbers, eg, Triazine or Benzotriaole

Light stabilisers, ie, HALS (Hindered Amine Light Stabilisers)

These additives, which absorb or stabilise UV light respectively, are often introduced to the base formula for the polypropylene material out of which the FIBC are woven. Both methods can retard the damaging effects of UV light but cannot stop it altogether.

Either way, photochemical degradation remains a reality that must be taken into consideration. The question becomes how well we can predict the lifespan of the FIBC given that it will be exposed to environmental stress. This is the job of the testing system.

Laboratory limits

The aim of testing is to recreate environmental strains in a controlled laboratory environment and examine the durability of samples against a battery of tests. In this way, accelerated laboratory UV tests allow quality control on FIBC without performing extended outdoor tests. Ideally, the results confirm the load-bearing capacity of the FIBC upon which decisions on usage of the FIBC are based.

Specific mention of UV resistance requirements had already emerged in European regulations for polypropylene sack used for transporting food aid in 1989. Since then the governing international regulation is the UV resistance Annex to ISO 21898:2004.

The regulation lays down rules for laboratory tests using UV B lamps (based on ASTM – G154-98). In a cycle that alternatively subjects samples to:

8 hours of UV light at 60°C

4 hours of condensation at 50°C

for at least 200 hours, the weathering strain on FIBC is simulated.

Once the exposure is complete, the samples are to be tested for:

Breaking force

Elongation of the fibre at the breaking point

The results are then compared to a control sample.

The UV resistance tests under ISO 21898:2004 give a common set of accelerated laboratory testing procedures that are repeatable and require the results of the tests to be expressed in terms that are comparable. Still, the International Standards Organisation concedes that:

“a number of factors of uncertainty are inherent in the procedure, so comparisons should be available between the method used and exposures in the environment in which the product is to be used”.

This caveat in the preamble of Annex A of ISO 21898:2004 hints at a central shortcoming of the accelerated UV resistance test with UV-B lamps at 60°C — it does not adequately represent real outdoor conditions. Therefore we cannot predict how well that test correlates to real-life exposure to light, temperature and other environmental influences in different climates from the arctic to the tropics where FIBCs are being used.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.