Introduction

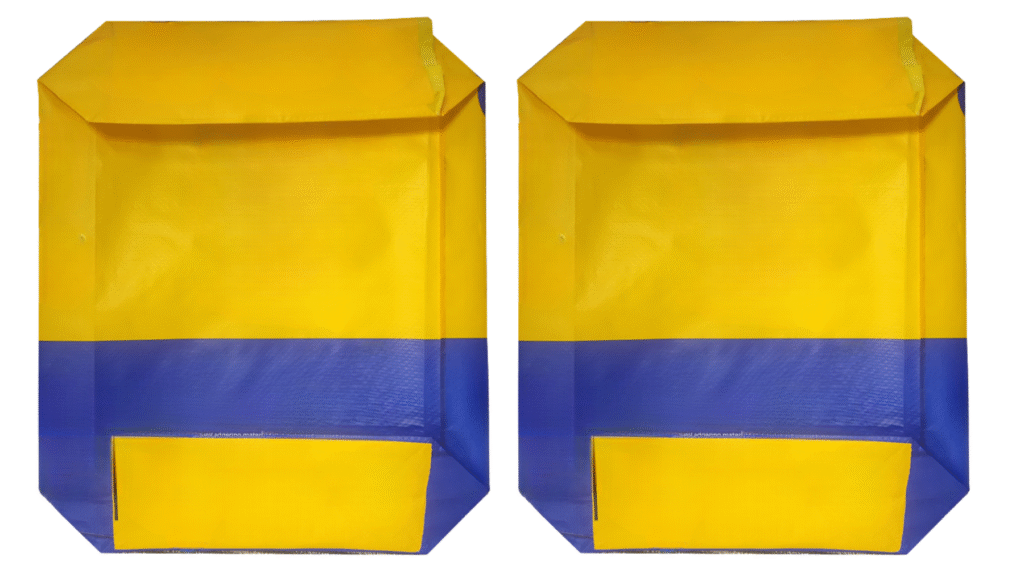

In the packaging industry, AD STAR bags represent a breakthrough innovation that has redefined durability, printability, and cost-efficiency for bulk packaging applications. Developed as a patented block bottom valve sack technology, these bags are primarily produced from coated or uncoated woven polypropylene (PP) fabric, offering the perfect synergy between mechanical strength and low weight.

Today, AD STAR bags have become the global standard for cement, fertilizer, resin, feedstock, and chemical packaging, thanks to their exceptional sealing strength, moisture barrier, and stack stability. Behind their superior performance lies not only precise extrusion and coating processes—but also high-performance masterbatches that determine the optical, mechanical, and functional characteristics of these bags.

What Are AD STAR Bags?

ADSTAR® bags are block bottom valve bags made from woven PP fabric that are either coated or laminated to achieve the desired sealing and barrier properties. These bags are produced using **ADSTAR® conversion lines**, which integrate:

Tape extrusion (for woven fabric),

Circular weaving,

Coating/lamination, and

Tubing and block-bottom formation using specialized machinery.

The result is a monolithic structure that combines the strength of woven fabric with the airtightness of film, offering an ideal alternative to traditional paper or jute sacks

Key Properties and Advantages of AD STAR Bags

Exceptional Mechanical Strength: High tensile and impact resistance ensures superior drop performance and puncture resistance.

Dimensional Stability: Block-bottom design provides uniform shape and stable stacking during palletization.

Moisture & Dust Barrier: Coated and valve-sealed structure prevents product contamination.

Lightweight Design: Up to 40% reduction in material weight compared to traditional multi-wall paper bags.

Enhanced Printability: Smooth surface enables advanced flexographic or rotogravure printing for branding.

100% Recyclable: Made entirely of polypropylene, promoting circular economy initiatives in packaging.

Applications of AD STAR Bags

Cement and Building Materials

Fertilizers and Agrochemicals

Polymer Granules and Resin Packaging

Animal Feed and Seeds

Industrial Powders and Chemicals

These applications demand not only mechanical endurance but also UV stability, moisture protection, and color fastness—which are directly governed by the masterbatches used during fabrication.

Masterbatches for AD STAR Bag Manufacturing

Masterbatches serve as the functional backbone of AD*STAR® bag production, influencing every stage of polymer processing—from tape extrusion to coating and lamination.

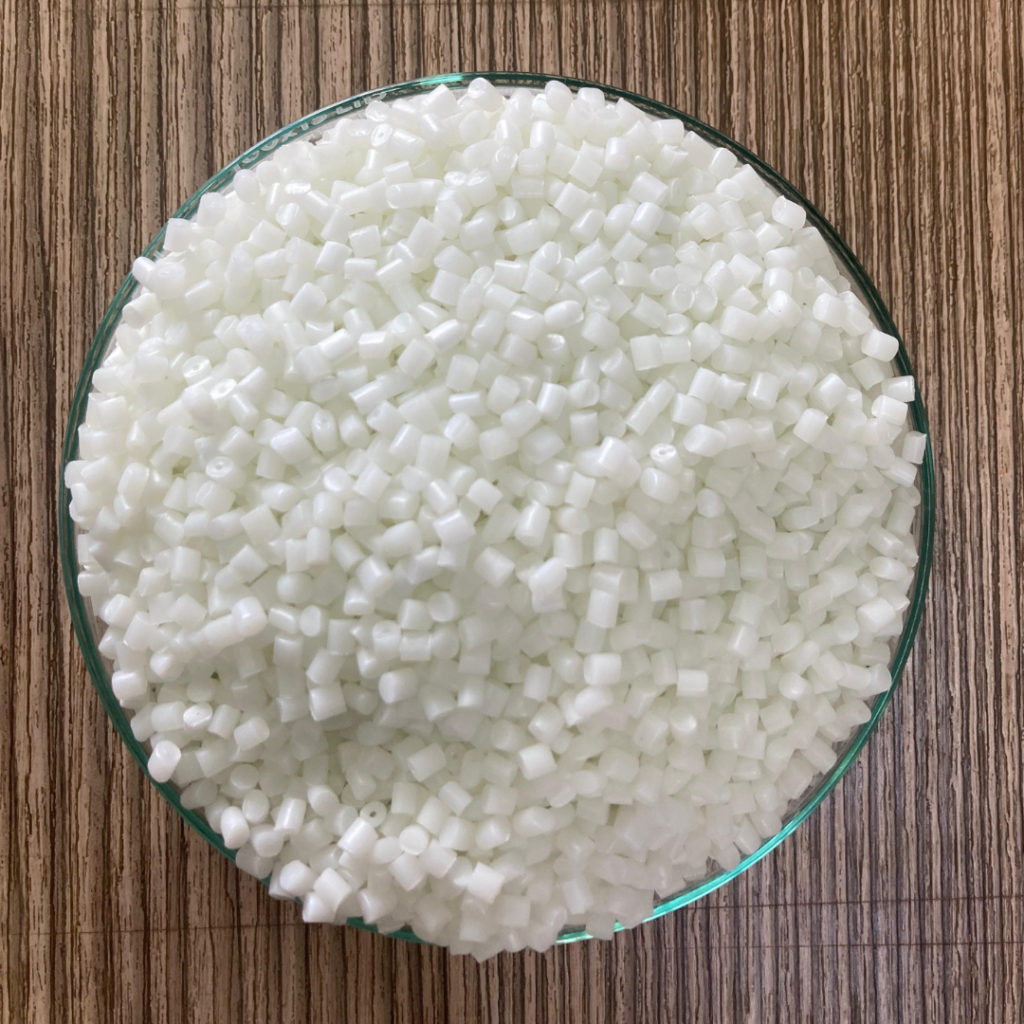

White Masterbatch (TiO₂ Based)

Provides excellent opacity, whiteness index, and UV reflection.

Improves film gloss and print adhesion during coating or lamination.

Commonly used in outer coatings for aesthetic appeal and print quality.

UV Stabilizer Masterbatch

Protects PP tapes and fabric from photo-degradation under UV exposure.

Extends outdoor life of bags stored in open environments.

Prevents color fading and mechanical brittleness caused by sunlight

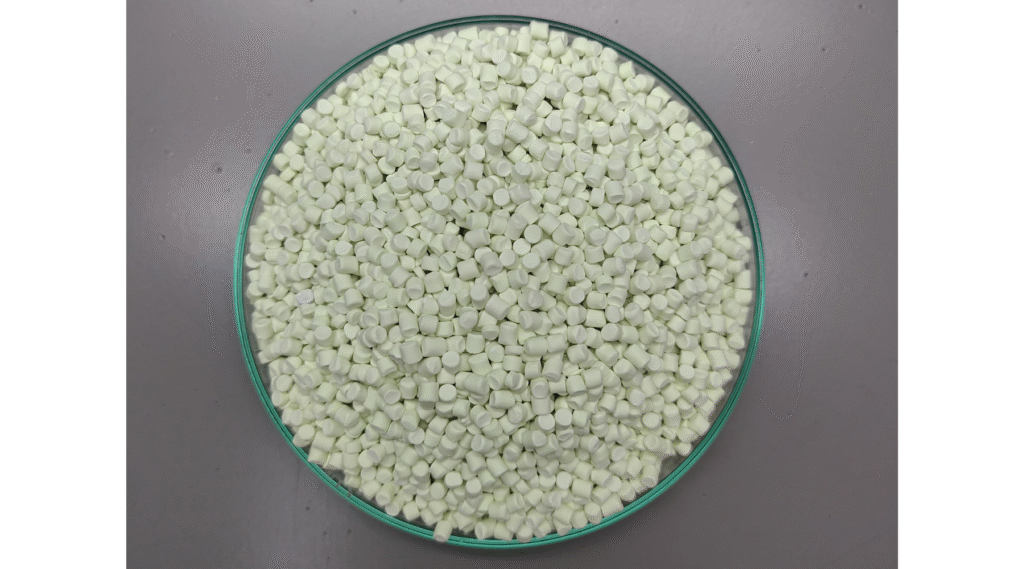

Color Masterbatches

Delivers brand-specific shades with high dispersion quality and color uniformity.

Formulated for high-temperature resistance during tape extrusion and lamination.

Antistatic and Processing Aid Masterbatches

Minimizes dust attraction and static discharge during filling and palletizing.

Improves extrusion throughput and film flowability.

Plast Modifier

Uniformity of tapes with minimal denier variation which is also helps in making low shrinkage tape/flat yarn.

How Our Masterbatches Enhance AD STAR Bag Production

At Bajaj Plast Pvt. Ltd., our masterbatches are engineered with precise rheological balance and high dispersion efficiency, specifically optimized for woven tape extrusion, lamination, and coating operations used in AD*STAR® bag manufacturing.

Technical Advantages:

High Thermal Stability: Ensures pigment integrity at extrusion temperatures up to 290°C.

Superior Dispersion Quality: Prevents die streaks and optical defects in coating films.

Optimized MI (Melt Index) Compatibility: Maintains consistent viscosity with PP raffia grades and coating resins.

Enhanced Weather Resistance: Formulated for long-term UV exposure in outdoor storage conditions.

Zero Moisture and Low Volatility: Prevents voids, pinholes, and delamination during film coating.

Our R&D team ensures application-specific tailoring—whether for cement-grade bags, fertilizer packaging, or export-grade laminated sacks—so that each masterbatch delivers consistent optical and mechanical performance under industrial conditions.

Why AD STAR Bags Are Essential for Modern Packaging

In today’s packaging ecosystem, AD*STAR® technology offers a superior alternative to conventional paper or PE bags due to its:

Extended Shelf Life for packed goods,

Reduced Leakage and Dust Formation,

Better Stacking Efficiency, and

Sustainability through 100% PP recyclability.

As industries move towards lightweight, eco-efficient, and high-barrier packaging, AD*STAR® bags are becoming indispensable for manufacturers seeking cost optimization, high mechanical strength, and environmental compliance.

Conclusion

AD STAR bags exemplify how innovative material engineering and masterbatch technology combine to revolutionize industrial packaging. With advanced white, UV, slip, and color masterbatches formulated by Bajaj Plast Pvt. Ltd., manufacturers can achieve higher process efficiency, superior aesthetics, and long-term durability in every bag they produce.

For modern packaging professionals, choosing the right masterbatch is not an expense—it’s a performance investment that determines the reliability and brand value of every AD STAR bag.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.