Plast Modifiers – Engineering Performance Beyond Polymers

In the ever-evolving polymer industry, the demand for advanced materials that deliver enhanced performance, durability, and processability is continuously increasing. Modern industrial applications—from automotive and packaging to infrastructure and electrical components—require plastics with highly engineered properties.

This is where Plastic Modifiers play a pivotal role, transforming standard polymers into high-performance materials tailored for demanding applications.

What Are Plastic Modifiers?

Plastic Modifiers, also known as polymer performance enhancers or impact modifier masterbatches, are specialized additives or masterbatches designed to modify and improve the physical, mechanical, thermal, and rheological characteristics of base polymers.

These modifiers interact at the molecular level within the polymer matrix, enhancing properties such as:

Impact resistance and toughness

Flexural and tensile strength

Melt flow index (MFI) and process stability

Gloss, surface finish, and transparency

Heat distortion and UV stability

Depending on the application, plastic modifiers are formulated using acrylic impact modifiers (AIM), chlorinated polyethylene (CPE), ethylene copolymers, compatibilizers, or reactive functionalized polymers, ensuring maximum compatibility with polymers like PP, PE.

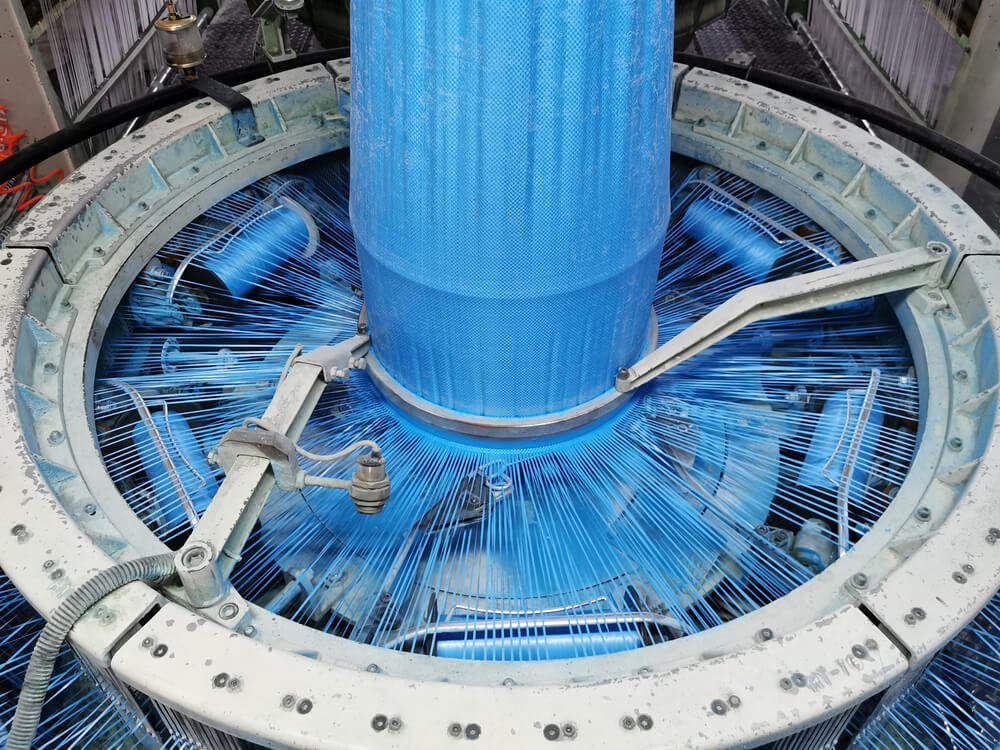

How Plastic Modifiers Are Manufactured

As a leading plastic modifiers manufacturer in India, we use twin-screw extrusion and reactive compounding technologies to ensure precise dispersion and polymer integration.

The process typically involves:

Selection of Base Polymer Carrier

Choosing a compatible resin (e.g., polyethylene, polypropylene) for uniform dispersion.

Integration of Functional Additives

Choosing a compatible resin (e.g., polyethylene, polypropylene) for uniform dispersion.

Controlled Extrusion & Compounding

Applying optimized shear, torque, and temperature profiles for molecular-level bonding.

Pelletization

Producing uniform granules for consistent dosing in extrusion or molding operations.

This engineered compounding approach ensures that our polymer modifier additives deliver maximum performance with minimal dosage.

Applications and Industrial Uses

Plastic Modifiers are indispensable across various industries where standard polymers require enhanced functionality.

Automotive & Engineering Plastics

Used to improve impact resistance, dimensional stability, and heat deflection in PP parts such as bumpers, dashboards, and trims.

Packaging Films and Sheets

Improve flexibility, tear strength, and puncture resistance in multilayer films, LDPE/LLDPE packaging, and laminated structures.

Wire & Cable Compounds

Enhance dielectric strength, elongation, and stress-crack resistance in PVC and polyethylene insulation compounds.

Building & Construction

Boost UV stability, toughness, and weather resistance in PE pipes, window profiles, siding, and sheets

Consumer Durables

Used to enhance surface finish, stiffness, and long-term durability in PP housings and appliance enclosures.

Why Plastic Modifiers Are Essential

Modern polymer formulations must meet complex mechanical and aesthetic requirements—something base resins alone cannot achieve.

Plastic Modifiers are essential because they :

High Thermal Stability: Ensures pigment integrity at extrusion temperatures up to 290°C.

Superior Dispersion Quality: Prevents die streaks and optical defects in coating films.

Optimized MI (Melt Index) Compatibility: Maintains consistent viscosity with PP raffia grades and coating resins.

Enhanced Weather Resistance: Formulated for long-term UV exposure in outdoor storage conditions.

Zero Moisture and Low Volatility: Prevents voids, pinholes, and delamination during film coating.

Our R&D team ensures application-specific tailoring—whether for cement-grade bags, fertilizer packaging, or export-grade laminated sacks—so that each masterbatch delivers consistent optical and mechanical performance under industrial conditions.

Why Choose Our Plastic Modifiers

As a trusted plastic modifiers manufacturer in India, Bajaj Plast Pvt. Ltd. delivers customized, performance-driven modifier solutions tailored to diverse polymer systems.

Our Impact Modifier Masterbatch range is developed using advanced polymer science to deliver:

Superior mechanical reinforcement for improved toughness and rigidity.

Stable rheology ensuring uniform melt flow and better mold filling.

Long-term weathering and UV protection for outdoor applications.

Excellent dispersion and compatibility with polyolefins and engineering resins.

Reduced additive loading, providing cost-effective formulation without compromising performance.

Each modifier grade is developed after in-depth rheological analysis, mechanical testing, and compounding trials, ensuring reliability and repeatability across production batches.

Our Modifier Grades :

Conclusion

In the competitive landscape of polymer processing, plastic modifiers are not optional—they are essential engineering tools that enhance product performance, extend lifespan, and enable sustainable material optimization.

By partnering with Bajaj Plast Pvt. Ltd., one of the leading plastic modifiers manufacturers in India, you gain access to technically advanced impact modifier masterbatches and polymer performance enhancers that empower your products to perform consistently under demanding environments.

Our continuous R&D focus, process expertise, and application-driven formulations make us the preferred partner for high-performance polymer solutions in extrusion, molding, and film manufacturing industries.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.