Plastics Processing Begins with Properly Dried Materials

From resin types to equipment, walk through everything you need to know about the importance of proper drying in your production process.

One of the most critical steps in successfully molding or extruding plastic parts is to provide proper drying of the resin. Proper drying ensures the best possible part quality.

Many types of resin are used in molding and extrusion. Choosing the right drying equipment depends on the properties of the resin and how much moisture the resin contains. It will also depend on the level of difficulty required to remove the moisture from the specific resin grade.

To achieve proper resin drying, manufacturers use an array of equipment including hot-air dryers, compressed-air dryers, desiccant bed, desiccant wheel dryers and drying hoppers.

Understanding Moisture Content in Resin

From managing the initial moisture of plastic pellets to using moisture measurement devices.

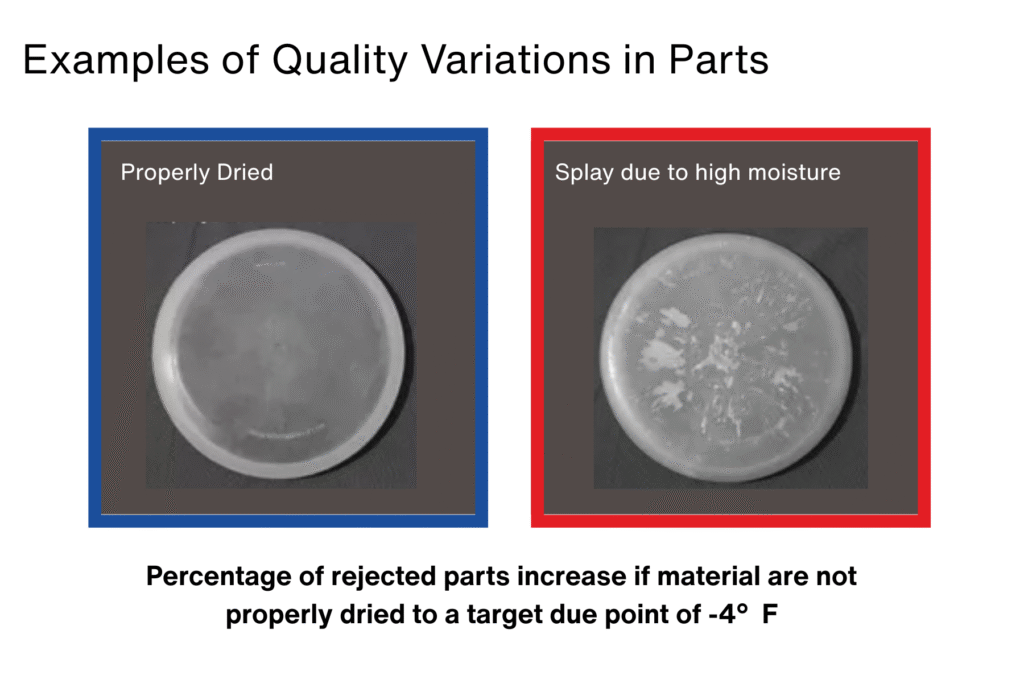

Processing resin that contain excess moisture can lead to problems with processing and final part quality. Too much moisture in resin can result in cosmetic or structural part defects – and in some cases, complete part failure.

While plastic pellets might appear dry, they might actually contain enough moisture to create quality issues with parts during production.

Moisture in resin is a function of many variables, from a material’s natural affinity to retain or reject moisture to the processing environment and equipment.

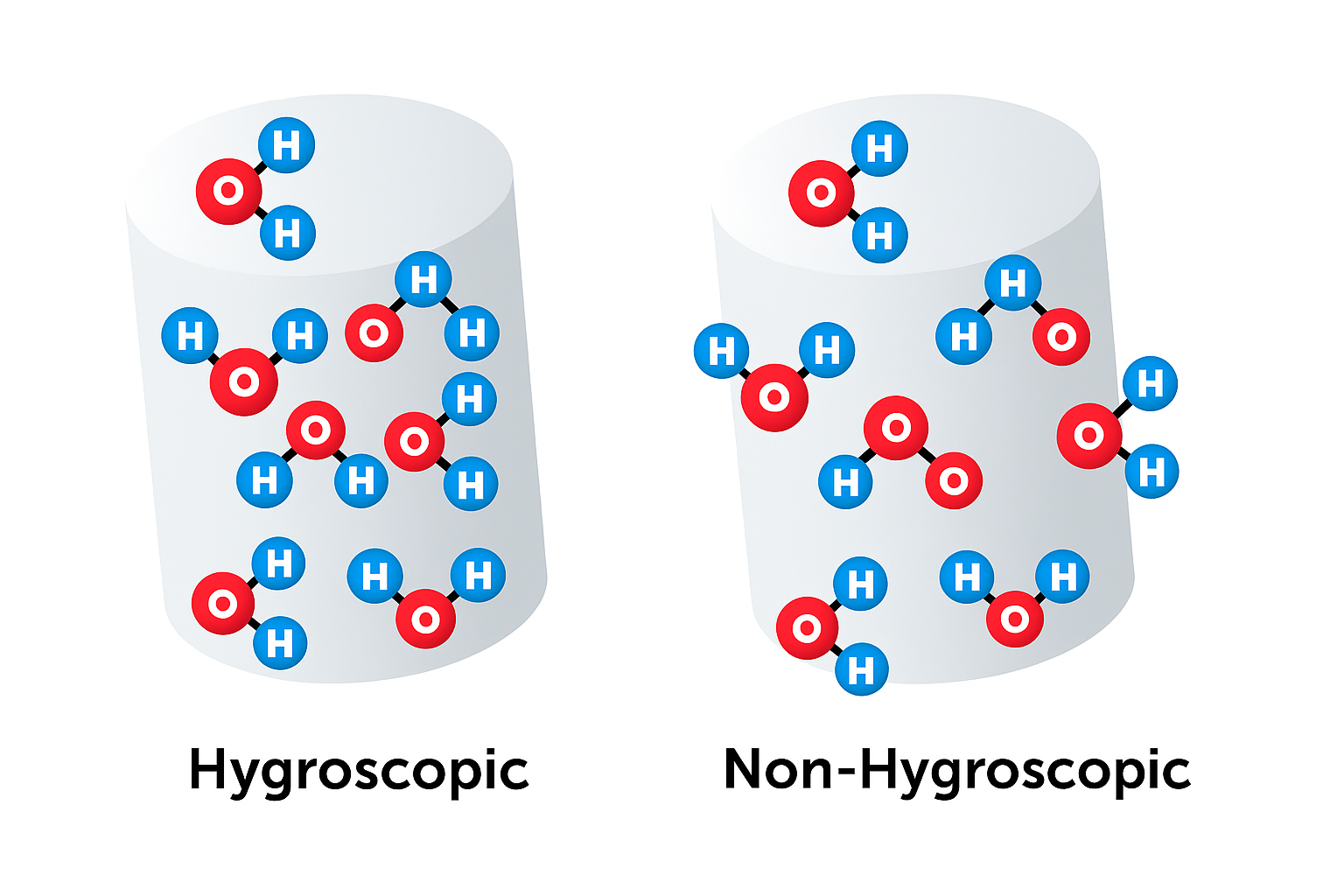

Hygroscopic polymers naturally attract moisture internally. Non-hygroscopic polymers don’t absorb moisture but retain it on the material surface.

Absorption of moisture from the atmosphere depends on multiple factors, including:

Resin type

Ambient conditions

Seasonal weather changes

Packaging/storage

Transportation

Manufacturing variables

Hygroscopic polymers naturally attract moisture internally. Non-hygroscopic polymers don’t absorb moisture but retain it on the material surface.

Moisture on or in resin will turn to steam when the material is melted for processing. Steam gets trapped in the cooling melt. These microscopic steam pockets can cause defects in the finished product (e.g., blistering) if not outright structural damage.

The Effect of Ambient Conditions

Conditions in and around where the resin is stored and manufactured.

The atmosphere is made up of:

- Nitrogen: 78% to 80%

- Oxygen: 18% to 20%

- Water vapor: 0.01% to 2%

Moisture is picked up by resin through exposure to ambient conditions.

Hygroscopic polymers absorb moisture in the pellet, where it is weakly bound. The percentage of moisture absorbed is dictated by the molecular structure. So-called intragranular moisture – moisture that travels deep inside a pellet – must be dried before processing. Hot air alone will not achieve the proper drying required.

Non-hygroscopic polymers, while not having an affinity for moisture, will pick up surface moisture if exposed to high humidity. Moisture on the outside of pellets (e.g., condensation) can be easily removed.

Note that adding a component to a non-hygroscopic material like polyethylene or polypropylene can make it hygroscopic and require dehumidified air drying.

The relative humidity and temperature of the surrounding air, combined with the length of the time the polymer is exposed to the atmosphere, influences the amount of water vapor a polymer will absorb.

Another consideration is dew point – specifically low dew point air. The dew point is the temperature at which moisture in the air begins to condense. Before a resin is exposed to heat, humidity can be removed from the air that will circulate in the drying system. Humidity can be removed by passing air through a desiccant bed or wheel. When this super-dry air is circulated into the drying system, it combines with heating of the air to create a moisture-absorbing flow into the drying hopper and through the material.

Initial Moisture Content

The amount of moisture a polymer resin contains before processing varies greatly depending on not only their inherent characteristics but also storage conditions, seasonal changes and other factors.

Whether sitting in a warehouse, being transported or entering a different climate, resins face moisture from multiple sources.

Resin delivered from the same supplier can contain different levels of moisture despite sharing the same recommended drying time and temperature. In fact, the initial moisture content of the same type of resin arriving in separate containers might vary significantly from batch to batch.

Initial moisture content varies by region. In a dry region, a resin will exhibit lower initial moisture than in a damp environment.

When buying resins, initial moisture content plays a significant role as well. Plastic pellets might contain a significant amount of moisture when being sold, which has led the industry to advocate for moisture analyzers to give buyers sound information when purchasing.

Problems Caused by Moisture

Using resin that has not been properly dried can create issues with production parts when processing. Moisture problems in injection molding manifest themselves in:

- Voids

- Splay and silver streaks

- Sinks

- Degradation of the polymer

- Nozzle droop

- Foamy melt

- Poor shot size control

- Lower melt viscosity

Moisture problems in sheet and profile extrusion manifest themselves in:

- Arrow heads

- Surface roughness

- Wave forms

- Trails of gas bubbles in the extrudate

- Degradation of polymer

- Surging/lack of size control

- Lower melt viscosity

Hydrolysis is another concern. When this chemical reaction occurs, it breaks the covalent bonds in the polymer chain. This reduces the polymer’s molecular weight, significantly reducing mechanical properties.

Benefits of Drying Plastic Resin

When moisture is properly removed from resins, multiple benefits can be seen in the process and final parts. These include:

- Improved melt uniformity

- Consistent line speeds

- Reduced corrosion of equipment and die

Examples of how proper resin drying achieves desired part outcomes in injection molding include:

- Preventing splay streaks: Moisture trapped in resin pellets boils, and the resulting steam leaves surface defects.

- Preventing brittleness: Unremoved moisture weakens the resin’s molecular bonds, making final parts too fragile.

- Preventing structural weakness: Moisture trapped in the resin can form bubbles that weaken the part.

- Preventing dimensional instability: Moisture’s effect on resin viscosity and shrinkage behavior can make parts not fit or work correctly.

Testing for moisture content

Numerous options are available to test the initial moisture content of industrial resins for molding and extrusion.

For instance, Karl Fischer Titration (KF) uses a chemical interaction with iodine and water to produce an electric current that can be measured. Moisture content can be determined from this current. These tests can take from 20 minutes to several hours.

Then there is rapid loss on drying (LOD) testing to achieve faster results. Using a heating source and an analytical balance with a sealed chamber, tests can be run in two to 10 minutes by radiating an even heat over a sample to precisely measure weight loss.

Resin Types

There are many resin types, but all fall into one of two categories, hygroscopic or non-hygroscopic resin types

Moisture affects different polymers to varying degrees, with nylon being one of the most susceptible to moisture regain.

A few common hygroscopic polymers, which demonstrate a natural affinity for absorbing moisture include:

- Nylon

- ABS

- Acrylic

- PET

- PBT

- Polycarbonate

- Polyurethane

Typical non-hygroscopic polymer resins, which collect moisture only on their surface, include:

- Polypropylene

- Polyethylene

- Polystyrene

- PVC

Note that adding a component to a non-hygroscopic material like polyethylene or polypropylene can make the compounded resin hygroscopic. This would then require a dehumidified air dryer to properly manage moisture removal from the resin.

Drying Basics

Understand how heat, dewpoint, drying time and airflow combine to affect resin moisture

When molding or extruding polymer resins, proper drying of those materials is essential to avoid errors in processing and defects in parts.

Four key concepts are essential for proper resin drying: air flow, temperature, dew point and drying time.

Airflow

Air transfers heat and removes moisture from the resin. Air volume must be sufficient to maintain even distribution through the cross-sectional area of the drying hopper.

With hygroscopic (water-absorbing) resins, low dew point heated air is directed through the material to disengage moisture molecules from the polymer chains. When that moisture moves to the surface, proper airflow carries it away.

Excess air flow is likely to occur if the dryer is oversized for the process and is connected to a smaller drying hopper. In some cases, material will not properly flow into the process machine.

When cool resin enters the drying hopper, that material acts as a heat sink that cools the air returning to the dryer. Cool return air maintains optimal operating temperature of the desiccant. In some cases, if the return air temperature is too high air aftercoolers are used to lower the temperature of the return air.

Recommended airflow can differ depending on the manufacturer of your dryer.

Problems that can arise from excess air flow include:

- High return air temperature

- Reduced desiccant capacity

- Higher dew point

- Blower damage

- Material flow issues

Drying temperature

The drying temperature is a very important consideration in all drying situations.

Heat is manifested in the movement of molecules. As polymer temperature increases, the molecules move more vigorously.

Heating the resin reduces the forces that bind water molecules to polymer chains. Above a certain temperature, water molecules become free to move about.

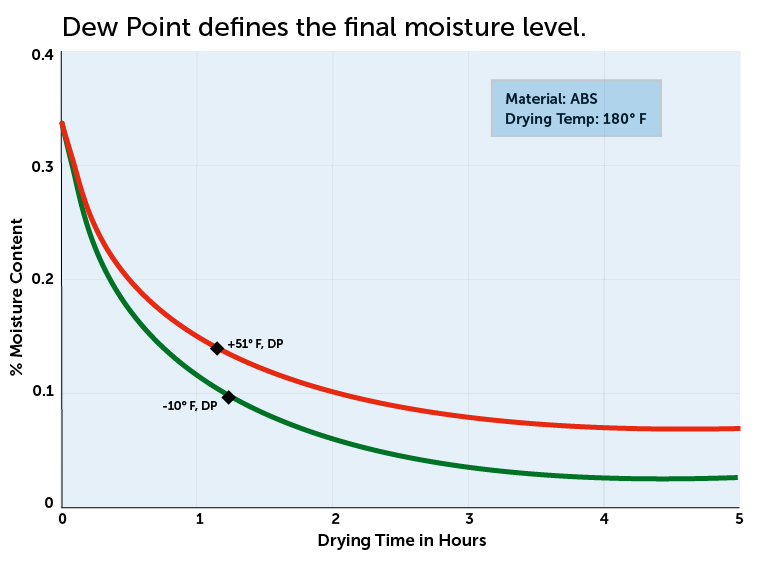

Temperature controls the rate of drying. For instance, ABS with about 0.35% moisture in an environment with a dew point of 0º F dries to about 0.1% moisture in:

- About 45 minutes at 208º F

- Two hours at 180º F

- Five hours at 160º F

It is always good practice to refer to the material supplier’s technical data for specific information related to your process and your material properties.

Dew point

The dew point temperature is a measure of how well the dryer is removing moisture from the drying air stream. Equal to 100% relative humidity, dew point temperature is the air temperature at which condensation occurs.

During the resin drying process, low dew point air is heated to create a super-dry heated airflow that absorbs and carries away moisture from inside and around the resin.

The final moisture level of a resin is defined by the dew point.

Drying time

Optimal drying of resin begins when the correct drying temperature and dew point are achieved.

Plastic pellets do not dry instantaneously. Water molecules must first be diffused from the polymer chain so they can migrate to the pellet surface of hygroscopic materials.

Drying times for the majority of resins vary from one to four hours at optimal temperatures (some specialty resins can take longer).

It’s important to note that it has been standard practice for material suppliers to recommend drying times and temperatures based on the assumed initial moisture content. By following these specifications, the resin will be properly dried for processing. It is critical to analyze the initial moisture content of your material(s) to avoid production and part problems.

To learn the optimal drying parameters for various plastics, consult the user guide provided by your material supplier, or contact your supplier directly.

Evidence of improper drying

Poorly dried polymer resins exhibit telltale signs that will alert processors that their materials contain too much moisture to be processed effectively. These include:

MOLDING

- Voids

- Splay and silver streaks

- Sinks

- Degradation of the polymer

- Nozzle droop

- Foamy melt

- Poor shot size control

- Lower melt viscosity

SHEET & PROFILE EXTRUSION

- Arrow heads

- Surface roughness

- Wave forms

- Gas bubble trails in the extrudate

- Degradation of the polymer

- Surging lack of size control

- Lower melt viscosity

Primary Drying Equipment

Learn the different operating requirements and benefits of current drying systems

Resin dryers provide simple, fast and effective drying for molding and extrusion. A variety of types are available, providing quality drying performance for nearly any application. Some of the most common types include:

- Hot air dryers: No desiccant

- Compressed air dryers: No membrane or with low dew point membrane

- Desiccant bed/dehumidifying: Single- or multiple-bed type

- Desiccant wheel/dehumidifying: Rotary wheel

- Vacuum-type dryer: Heat and vacuum are used to remove material moisture

Dryers are available for molders and extruders processing as little as one pound per hour to over 6,000 pounds an hour.

Options range from small, energy-efficient portable units to large central systems. Many drying solutions feature a compact design with integrated conveying, ensuring dried material is delivered directly to the process machine

Dryer types

Hot air dryer:

These simple systems are the most economic resin dryers. Using a single-pass process, these dryers pull atmospheric air through a filter and through the heater, pushing the heated air through a drying hopper and exhausting it back into the atmosphere.

Ambient air is heated and introduced into the drying hopper. Surface moisture is removed from non-hygroscopic materials. Non-hygroscopic materials are typically dried at 180º F or less. For hygroscopic materials the air heats the pellet, and internal moisture is brought to the surface, allowing it to dry. The maximum hot air temperature is driven by the material’s softening (not melting) temperature. This type of dryer is not typically used for hygroscopic materials unless there are small quantities used from a sealed bag of resin.

Compressed-air/dehumidifying/membrane dryer:

Primarily used for low-throughput applications and small machine applications due to the amount of compressed air required. High pressure compressed air is expanded to produce higher volumes of low-pressure air. The expanded air is passed through a heater and then enters the drying hopper. Heated wet air is discharged from the drying hopper into the atmosphere.

Non-membrane versions lower the plant dew point air (to process) by 40ºF to 50ºF. Compressed plant air typically provides approximately 0 to +15º F dew point air. In cases where the central compressed air system is equipped with a central compressed air dryer, this may reduce the compressed air dew point enough (0 to -15º F) to allow proper drying without the use of an additional membrane on the dryer.

Membrane versions run compressed air through a membrane, which removes moisture from the air. Compressed air dryers which use a membrane can produce -40°F air or better.

Some applications may require a HEPA filter on the air outlet of the drying hopper to capture any exhaust dust particles and prevent them from entering the atmosphere.

Desiccant bed/dehumidifying dryer:

This type of dryer uses a desiccant material (e.g., beads) to absorb moisture. As beads become saturated, they go through a regeneration process to remove moisture which will allow the desiccant to regenerate and allow moisture to be absorbed again into the beads (the process of adsorption). Extremely hot air (400 to 800°F) is passed over the desiccant to release the moisture they’ve absorbed from the airstream. However, the beads must be cooled before returning to the drying process to avoid melting the resin with a temperature spike when the bed is put online for processing.

Multiple-bed desiccant technology can use one or two blowers. The blower(s) provide process, cooling and regeneration air, utilizing a switching valve to direct air through the desiccant beds.

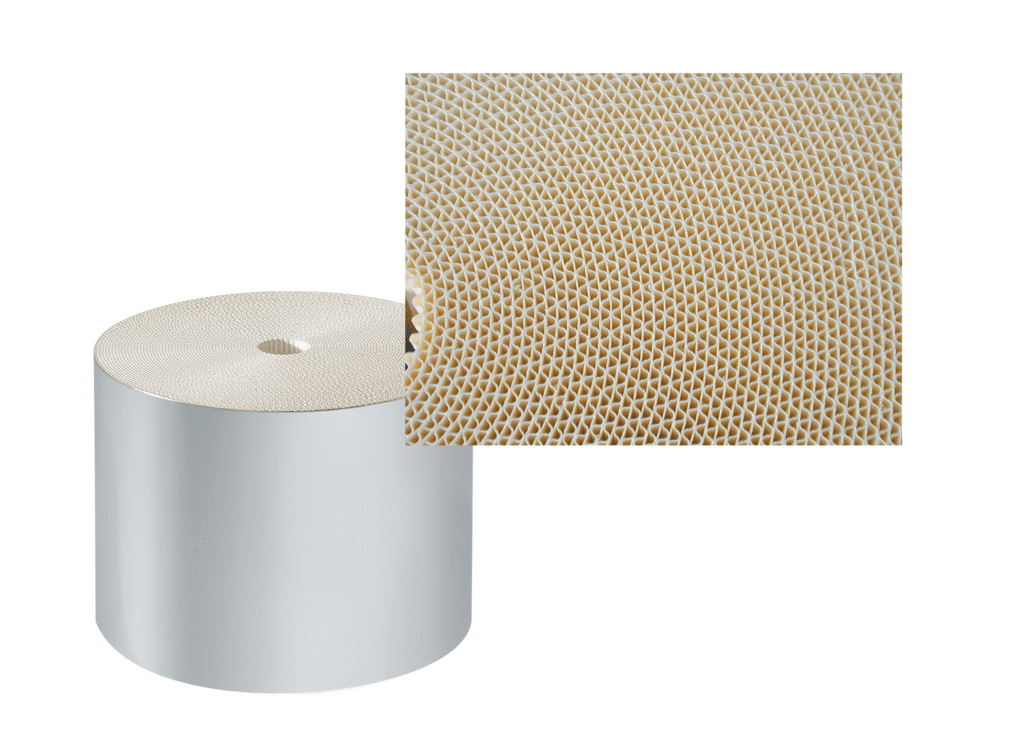

Desiccant wheel rotor type (honeycomb) dryer:

Desiccant wheel dryers provide a different type of desiccant drying. They are far more efficient, more compact, and require less maintenance. Traditional dehumidifying dryers use a large volume of molecular sieve (in pellet form) composed of at least 30% clay. This desiccant bead tends to degrade over time. The desiccant wheel design is completely different. It is constructed from a pure molecular sieve impregnated onto a durable media. This material is formed into a reinforced honeycomb structure.

Desiccant wheel dryers provide stable, extremely reliable dew point in nearly any ambient condition. Stable process temperatures mean no bed spikes. These dryers go from cold start to drying in minutes. They can achieve higher-than-average process air flows using minimal energy due to low pressure drop across the rotor. Large surface area to volume ratio of desiccant provides faster adsorption and desorption conditioning of the desiccant. The honeycomb has a thin layer of desiccant that uniformly absorbs moisture. At regeneration, the absorbed moisture is easily evaporated off the media, this allows the dryer to deliver effective continuous drying as the rotary wheel slowly rotates.

A wheel dryer operates through three simultaneous processes: drying, regeneration and cooling:

- In the drying loop, humid air from the drying hopper passes through a filter, cooler and blower to the desiccant wheel, extracting moisture from the process air before returning to the drying hopper.

- The regeneration process removes moisture from the desiccant wheel using a separate filter, blower and heating chamber, expelling hot, moist air external to the dryer.

- Cooling follows regeneration, where a portion of low dew point, cooled air is directed to the desiccant wheel (before the heater) enhancing its moisture absorption for the next drying cycle.

Vacuum dryer

Vacuum dryers reduce the boiling point of water. For instance, at a vacuum of 90%, water boils at 122º F. Current designs feature an insulated vacuum vessel; insulated stainless steel hopper for drying temperatures up to 662º F; load cells that control material level and show material consumption; a dry air membrane for purging the vacuum vessel; and an insulated retention hopper for dried material. Pellets are heated to the required temperature. When the vacuum is applied, water vapor inside the resin boils. Resin can be ready for processing in a short amount of time compared to traditional drying. Vacuum dryers have fewer moving parts and work well for some processing applications.

Controls

Controls monitor and maintain optimum performance in the drying process. Today’s control platforms offer many control and diagnostic features including air flow and temperature control. Some platforms are capable of adjusting dew point parameters and incorporate dryer maintenance routines in the typical operation and use.

Dryer controls typically feature colorful, easy-to-use touch screens with visual representation of drying parameters and processes. Intuitive layouts allow operators to quickly learn and initiate dryer functions.

Dryer controls are keeping up with the data-collection requirements of Industry 4.0 used in the plastics industry. Advanced controls optimize moisture removal with capabilities like energy control algorithms and integrated conveying controls with purge takeoff capabilities.

Remote monitoring capabilities let operators keep tabs on operations form their phones, tablets or computers.

Process data collected by modern dryer controllers enables smarter facilities, with trend charts that show critical parameters.

Drying Hoppers

Drying hoppers are required for all types of drying applications. The drying hopper holds the correct amount of material in residence for the proper amount of time. This allows the dryer to remove the required amount of moisture from the resin.

The design of resin drying hoppers is another critical consideration for plastics drying systems. Flow design, sizing and insulation are the key factors to understand when choosing the ideal drying hopper.

Flow design — mass flow or funnel flow — affects material passage through the hopper.

In a mass flow design, all material flows through the hopper at the same rate, and material flow is counter current to the drying air. In a funnel flow system, material flows faster through the center of the hopper and slower along the hopper side and walls. Mass flow designs are required to allow for proper residence time of the material before it enters the process feed throat.

Sizing your drying hopper can be done by weight or by volume. Small drying hoppers average from 0.1 cubic foot capacity to 30.0 cubic feet These are typically mounted on a floor stand or a portable cart and are generally located next to or near the process machine. For some lower-throughput applications, the drying hopper can be mounted directly to the machine throat. Larger drying hoppers average 30 to 425 cubic feet and are typically mounted on a floor stand or mezzanine due to the larger footprint requirements of the equipment.

To size your drying hopper by weight, it must equal the throughput rate of the machine (pounds per hour) multiplied by the residence time of the material in hours. For example, if your machine can move 100 pounds per hour and the material’s residence time is four hours, that would require a drying hopper with 400 pounds of capacity.

To size your drying hopper by volume, the calculation is machine throughput rate (pounds/hour) multiplied by material residence time (hours) divided by bulk density (pounds per cubic foot). For example, 100 pounds of material requiring four-hour residence time at a density of 40 pounds per cubic foot would require a drying hopper with capacity of 10 cubic feet.

Many engineering resins can be dried using 35 to 40 pounds per cubic foot as a reference for the virgin pellet bulk density (refer to material supplier data sheet). Filled resins – for instance, ABS with 40% glass filler – weigh more, while regrind material tends to be lighter density. Particle size and shape of regrind also affects the material density. Examples include

PE virgin pellets: 32 to 35 pounds/cubic foot

PE film: 7 to 11 pounds/cubic foot (depends on gauge)

Non-insulated drying hoppers are less desirable for a number of reasons:

- Waste energy

- Excess heat in process area

- Compromised operator safety

- Material adjacent to hopper walls will be at less-than-selected set-point temperature

Resin Moisture Measurement Devices

Understanding the initial moisture content of plastics resins is essential to determine how long to dry them. Drying time and temperature guidance from material suppliers often is based on an assumed initial moisture content, which can lead to resins being overdried or under dried – creating process and part problems.

Resin moisture measurement devices are available in offline (laboratory) or inline formats. Lab devices can also provide complete chemical analysis, while inline devices are often less expensive and easier to use.

Offline devices include:

- Loss-in-weight analyzers: Measure total change in weight of the material when the resin sample is heated at a specific temperature.

- Moisture-specific analyzers: Use a chemical process to detect moisture levels.

Inline moisture analyzers include:

- Capacitive sensor: Measure changes in capacitance caused by dielectric changes.

- Microwave: work on the principle that water has a significantly higher dielectric constant than most other materials. Due to a water molecule’s dipolar effect, a microwave resonator’s resonant frequency changes with variations in moisture content. These variations are detected by the sensor electronics, which are scaled by the calibration process to provide a precise readout of the moisture present.

- Near-infrared: Excite water molecules with light beams to measure light absorption in wavelength, which indicates resin moisture content.

Drying Systems

How to determine which drying system is best for your processing needs

Drying systems are available in a variety of configurations, each with their own unique capabilities and advantages. Drying systems should be evaluated based on a processor’s overall throughput requirements, as well as other considerations like material changes, floor space and access to utilities. Current and future needs should be considered so that you have designed in expansion for the system.

The most common resin drying systems include:

- Machine mount units

- Portable cart systems

- Portable cart systems with integrated conveying

- Central drying systems

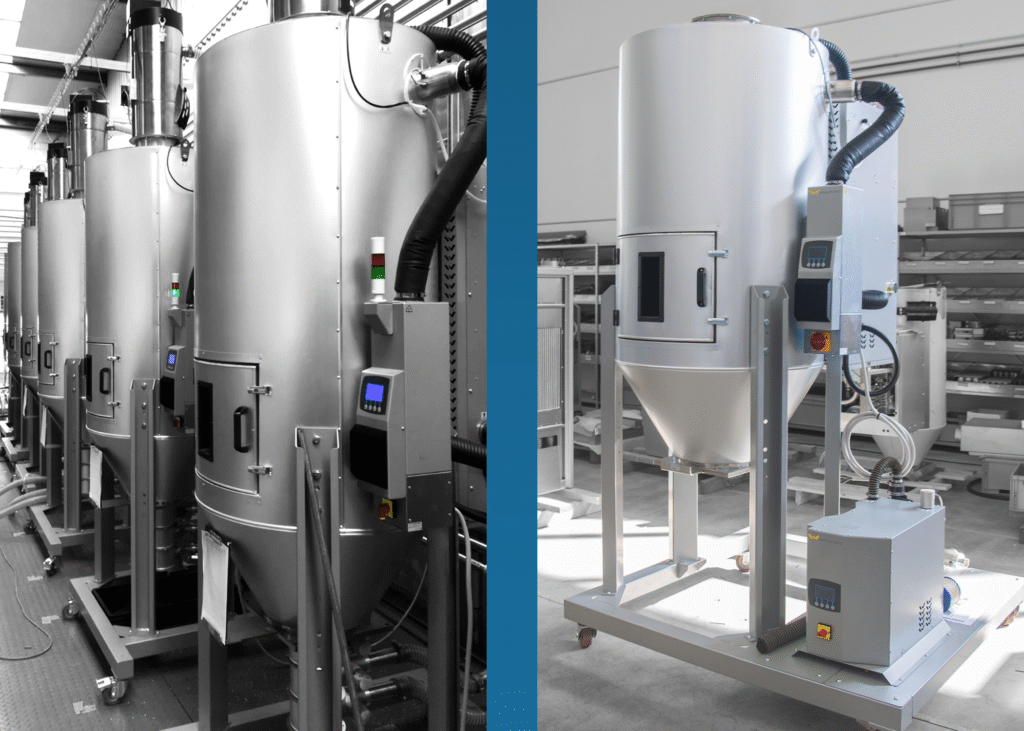

Central Resin Drying Systems

Central drying systems typically feature one large central dryer with multiple drying hoppers on a common piping and control platform. The dryer runs and provides full air flow in a large dryer loop. Manual or automatic air regulation valves control air flow to each individual drying hopper. One large central heater or smaller individual heaters are supplied to provide heated air to each drying hopper.

Another central drying configuration is designed to provide a grouping of smaller dryers in a row. Each dryer would be sized for the main throughput of the resin it is designed to process. In this case, the system provides ultimate control and processing of each resin. If there is a dryer problem, the rest of the system is unaffected and continues to operate. If another material is added, another dryer module can easily be added to the drying system hopper bank. In this case, each material is provided with the most efficient operating parameters and control to achieve proper drying and delivery of resin to the process.

Central resin drying systems are a failsafe against production slowdowns and stoppages because work can continue even if one drying unit fails. New dryer units are easy to add on, in any size and dimension.

While easy to expand, central systems still use less floor space. Central drying systems allow dryers, hoppers and even bins of material to be moved away from the area around the primary machine. This makes central drying systems safer and easier to clean.

A central system could be as simple as a single small dryer serving two or three hoppers on a cart. A central system can also be a series of smaller dryers/drying hoppers each sized for the specific volume of a dedicated resin. In the final scenario, the central system can consist of one large dryer supporting up to 12 drying hoppers on multiple carts. Central systems can be configured to dry from as little as one pound of material up to thousands of pounds of resin.

One dryer or multiple dryers?

A central resin drying system will feature either one large dryer with several drying hoppers connected or a row of individual dryers with integrated drying hoppers.

It is preferable to have individual dryers next to each other to make a central system dryer bank. This affords processors optimum control of each individual material and precise, individual control of air flow and temperature to get the optimum drying performance characteristics.

Alternatively, with only one dryer and multiple drying hoppers, processors are relying on one large unit to control material flow, temperature and air flow to several drying hoppers. In this case, the resin drying system might not be running as efficiently as it could. Worse, if a dryer encounters a problem, the processor might have to shut down the entire system rather than just one station. While individual drying cells require slightly more floor space, if one goes down, it can be removed from the line while the others are running. If the system is expanded, additional dryer modules can easily be added.

The total energy consumption of each type of system is comparable. With an individual dryer and drying hoppers, processors control the actual material and actual drying parameters for the material – the ideal scenario for the best drying performance. That configuration might use slightly more input power upon installation, but it will certainly require less operating power because it is using only the energy it needs to run and dry a specific material. A single-dryer system with multiple hoppers uses a larger main blower, which can be turned down only so much based on the total system requirement.

To achieve contemporary requirements for energy efficiency, modularity and functionality, having individual dryers set up in a bank provides more advantages overall.

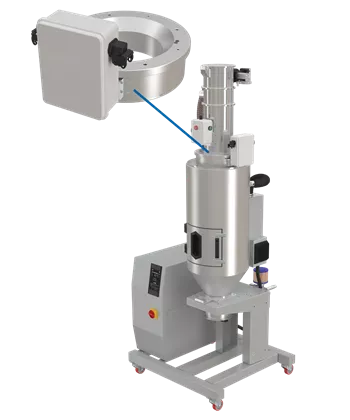

Portable resin drying systems

Portable resin drying systems are often an interim solution between machine-side and centralized drying systems. They are also a good choice for custom molding operations.

Often mounted on a cart, portable resin drying systems feature a drying hopper, a unit to deliver material to the hopper and another unit to bring material to the machine.

Throughput for portable resin drying systems can be as little as 1 pound per hour up to 400 pounds an hour.

While multiple materials can be managed with multiple portable systems, navigating changeovers on valuable production floor space requires careful planning and execution.

An all-in-one portable integrated conveying system allows operators to automatically convey material to the drying hopper and the process machine with integrated controls. This means that no additions or expansions to existing conveying systems are required. In addition, when equipped with an optional remote proportioning valve, two materials, typically virgin and regrind, can be automatically conveyed to the drying hopper, eliminating the need to mix the two prior to drying.

Portable resin drying systems with integrated conveying

An all-in-one portable integrated conveying system allows operators to automatically convey material to the drying hopper and the process machine with integrated controls. This means that no additions or expansions to existing conveying systems are required. In addition, when equipped with an optional remote proportioning valve, two materials, typically virgin and regrind, can be automatically conveyed to the drying hopper, eliminating the need to mix the two prior to drying.

Machine-Mounted Dryers

Machine-mounted dryer/hopper configuration are generally designed for lower throughput. On higher-throughput extrusion applications, a drying hopper can be mounted to the process machine, and the dryer would sit next to or near the machine to connect to the drying hopper.

Any machine movement or cycling could seriously affect the mechanical design integrity of the system. In these cases, it would be better to mount the dryer above the throat on a stand that straddles the process machine or on a mezzanine directly above the feed throat of the machine. This removes the dryer and hopper from direct mechanical impact and fatigue.

At one time, it was common practice to mount the dryer/drying hopper to the process machine. In today’s production environment it is considered common practice to install the drying system next to or directly above the process machine feed throat.

Specialized Drying Equipment

Understand the functions and benefits of the halo weigh ring, plasticizer/volatile traps, crystallizers, silo dehumidification systems, gas-fired process heaters and moisture monitors.

Creating the right system for drying resins extends well beyond choosing the optimal machine for your process and materials. An array of special equipment is available to handle important unique aspects of the drying process.

This specialized equipment covers everything from real-time automatic measurement of material usage and drying parameters to contaminant removal.

Halo Weigh Ring

A Halo Weigh Ring is a device that enables real-time measurement of material throughput. It also controls drying parameters according to production needs.

Installed below the vacuum receiver filling the drying hopper, the Halo will provide precise control over a critical aspect of plastic production costs: the raw material. The Halo monitors material consumption for individual machines and the entire production process, complete with long-term data storage.

Benefits of the Halo Weigh Ring include:

Accurate measurement of material throughput in pounds/hour in real time.

Automatic control of dryer and drying parameters throughout production.

Maximum production by setting an alarm for exceeding the maximum throughput, avoiding conveying undried material to the production machine.

Conveying system control by weight vs. time.

Batch size control by entering a desired material quantity; the Halo keeps track of accumulated weight, displays remaining time and halts loading when batch weight reached.

Data storage as the Halo detects and displays hourly production in pounds/hour and precise quantity of material used. Halo calculates and stores all material loaded by the receiver, which can be retrieved for data analysis hourly, daily, monthly or for a custom time. The system tracks the conveyed material quantity. Cumulative material consumption data is accessible in various formats and can also be integrated into other systems through open communication channels

Plasticizer/Volatiles Trap

When drying resin at high temperatures or when the material has some special additives that will release from the resin when heated, plasticizer traps can be used to capture the contaminant. The resulting oil and other contaminants can foul drying system filters, housings and desiccant. A plasticizer trap can be installed on the return line of a drying system (between the drying hopper and the inlet of the dryer return line) to remove volatiles and contaminants from the hot return air. Contaminants and volatiles are condensed into liquid and drained from the filter system. Using a plasticizer trap when needed will protect your dryer system and keep it running at peak performance.

Crystallizers

For processors who use or make large volumes of scrap or recycled PET or PLA, crystallizers are vital to convert those materials from an amorphous to a semi-crystalline state so they can be processed properly.

Crystallizers come in two types – hot-air hopper and infrared drum – and are sized based on the amount of material to be crystallized every hour. Crystallizers can process material by the batch or in a continuous process.

A crystallizer is a heating device that raises the temperature of granulated amorphous material past its glass transition temperature while keeping that material just under melting temperature. At crystallization temperature, crystalline structures grow and align within the molecules of amorphous material.

If a material is not crystallized, it will agglomerate in its amorphous state and disrupt material flow, resist drying and get stuck downstream.

Silo Dehumidification System

Metal silos that hold resin also can retain dampness depending on changes in external temperature and humidity. To keep resin from absorbing excess moisture from the environment, a silo dehumidifier is used to provide a blanket of dehumidified air above the material.

Usually installed at the silo base, a silo dehumidifier uses to remove moisture from the air. One silo dehumidifier can function with more than one silo as long as it is sized for the application and the process blower has enough pressure for the installed piping run.

Gas-Fired Process Heaters

Gas-fired process heaters provide fast, efficient direct or indirect heating. They are an alternative to electric powered heaters. Fueled by natural gas or propane, gas-fired process heaters come in vertical or horizontal configurations. These heaters are used for very high throughput, higher temperature applications. Gas-fired process heaters can be used for central drying applications, with one heater controlled by the dryer and another controlled remotely at the hopper.

Dewpoint Sensors (machine-installed or portable)

Dewpoint sensors are a standard option available on most dryers. They monitor the moisture of the process air leaving the dryer and going into the drying hopper to dry the resin. Dewpoint sensors can alert operators when the desiccant or regeneration cycle is failing to keep the air dry and can be set to regenerate the dryer when the desiccant bed reaches a desired setpoint. Portable dewpoint meters can be used to verify the efficacy and accuracy of onboard dewpoint sensors. Portable dewpoint sensors can sample air sent to the hopper, within the hopper or returning from the hopper, as well as at the feed throat.

Resin Dyer System Installation

Understand configuration and insulation options

Installing resin dryers and systems can be as simple as a basic dryer on a cart, accompanied by general installation information – or as complex as a central resin drying system that requires an installer to configure all the pieces.

Installation specifics depend on whether you are using a drying system near the processing machine(s) or a more complex, remotely located central drying system. Extrusion processes are generally ideal for drying systems that are close to the machine, while molding operations often benefit from remote central drying systems. Each processor has its own requirement and design preference.

Insulation

Insulating key components of your resin drying system, including the hopper(s) and dryer(s), is essentially to retaining optimum heat throughout the resin drying process.

Drying hoppers generally are insulated. The thicker the insulation, the better the heat retention. Most drying hoppers have 2-inch thick or thicker insulation. For dryers, components that should be insulated include high-temperature flex hoses and hard metal ducting routed from the dryer to the drying hopper.

Insulate dryer hoses and piping that carry hot air from the dryer to the drying hopper inlet. The hose returning air from the top of the hopper to the dryer should never be insulated. It is important to reduce the dryer return air temperature to allow for optimum desiccant regeneration.

Component placement

In any dryer installation the placement of those components must be considered relative to the overall extrusion or molding process and the workflow.

Portable drying systems generally feature a dryer, hopper and loader on a rolling cart that can be moved from one machine to another. Larger systems should be more stationary and are not considered portable.

Mezzanine-mounted drying systems, located directly above process machines, save floor space and can supply resin to multiple machines.

Central drying systems

Central drying systems are optimal for use with multiple resin types requiring many changeovers. Central drying systems can be built with multiple dryers or a single dryer.

Application requirements are a key consideration for the layout of your resin drying system – if you are also blending and conveying materials.

Process heaters can be included in the dryer cabinet with small systems or on or near the drying hopper in large systems. This minimizes heat loss between dryer and hopper and maximizes the energy efficiency of the drying system.

Hose requirements

Resin drying systems use multiple hoses to convey air and materials from storage through drying to processing.

- Heated dry air to the drying hopper – insulate.

- Hot air within the dryer cabinet components – insulate.

- Returning air from the top of the hopper to the dryer – no insulation.

Material flow

When planning your equipment layout, consider the flow of resin from storage into the drying hoppers and then from the drying hoppers into the process. The design should consider optimum flow, minimal material degradation and protection of the dried material after it leaves the drying hopper and is conveyed to the process.

The distance from the drying hopper discharge to the process machine must take into account excessive heat loss by the resin and the amount of time the resin sits in the material lines. It is important to protect the resin and minimize the chance that it can regain moisture after it has been dried and before it is processed.

Consideration should be made to provide closed loop conveying, conveying with dry air and/or purging material from the drying hopper into the process machine. These would be discussed as separate topics during the system design process.

For long conveying distances between the drying hopper and process machine, it might be beneficial to add a small conditioning dryer/drying hopper near the process machine to bring the material back up to temperature and to condition the dried resin and prevent the material from absorbing ambient moisture from the environment.

Purging the material line each time material is conveyed from the drying hopper to the process machine is a good way to ensure dried resin is contained at the source and then used in minimal amounts (enough for the process machine throughput requirements plus a small reserve). In this type of system an insulated machine hopper can hold enough reserve material and keep it from losing too much heat prior to being used in the process. Care must be taken when designing this type of system due to convey time lost to the purging process. Your system design expert can properly size the system to avoid any chance of under sizing your throughput for the system.

Each resin has different material properties and different levels of moisture regain potential. Understanding this will allow you to design a system that addresses the concerns but does not create a system that is overengineered.

Controls

Contemporary dryer system control screens generally are set at the factory and are ready to perform right out of the box to communicate system parameters and maintain them.

In most cases, a resin drying recipe can simply be loaded into a controller’s recipe book with easy-to-use touchscreen controls. With stored resin drying recipes, once a material is loaded into the dryer control, it runs automatically at the prescribed temperature, air flow rate and drying time. Preset recipes can be overridden by expert processors.

System utilities

Planning the location of a resin drying system must consider the availability of and ease of access to an electrical supply, gas supply, compressed air and water. Always check and comply with local codes and installation requirements for all utilities. Your equipment supplier can provide specific requirements for the equipment you are installing for your process. In most cases, installation support can be quoted and sold as part of the new system purchase.

Resin Dryer Maintenance

Keeping process and regeneration heaters, blowers, filters and desiccant clean and effective to run at peak efficiency.

Because resin drying machines and systems are essential to successful molding and extrusion operations, processors must maintain that equipment in peak operating condition.

Covered below are the key elements of resin drying systems that must function properly, including:

- Process heaters

- Regeneration heaters

- Desiccant beads/wheels

- Blowers and hoses

- Filters

Always remember to remove power from the equipment and follow all recommended safety guidelines before opening and servicing equipment.

Process heaters

To ensure process heaters are properly heating the air to elevate material temperatures – which will aid in removing moisture from the resin – they must be inspected to ensure they are reaching desired temperatures consistently.

If process heaters are slow to reach an optimum temperature or fail to reach the desired temperature, the control parameters may need to be reset or the heater element is likely to be failing (or burned out).

Take the dryer offline before replacing the heater. Replace all the heaters at the same time in a multiple-element setup. Note that if one heater has failed in a heater bank, it is likely others might also be near failure mode. It is good practice to replace all heaters in a bank if there is any uncertainty about their operating condition.

Regeneration heaters

Regeneration heaters are used in the drying process to aid in the moisture removal of the saturated desiccant bed or rotor wheel section. This prepares the desiccant to go online and be at peak efficiency for moisture removal. Temperatures of regeneration heaters are generally preset by the manufacturer.

The effectiveness of regeneration heaters can be monitored by a variety of methods:

- Observing heater contractors, controller lights, thermometers or amp meters.

- Measuring heat output.

- Comparing actual temperature to manufacturer specs.

- Monitoring regeneration exhaust temperatures at the dryer exit point.

- Failure to reach low dew point.

Desiccant beads and wheels

Desiccant materials vary in composition, and therefore usable life.

Desiccant beads, made up of 30% clay binder, break down faster in repeated heating and cooling cycles. This can produce dust that can contaminate resin. Desiccant wheels, made of 100% molecular sieve material, can last up to 15 years (or longer) depending on proper use and maintenance.

To replace desiccant beads

- Turn off the dryer and wait until it cools down.

- Open the desiccant bed container.

- Scoop desiccant out of the bed(s).

- Vacuum out the desiccant dust.

- Pack new beads tightly, avoiding air pockets (vibrate the tank(s) if necessary).

To replace desiccant wheels, replace either the wheel alone or the complete rotor wheel assembly, depending on manufacturer’s recommendation.

Blowers and hoses

Resin drying systems typically use two blowers to maintain the necessary air flow to dry materials: a process blower and a regeneration blower. The process blower is located near the drying hopper or in the drying cabinet, while the regeneration blower is inside the drying cabinet and removes moisture from the desiccant to continue the resin drying process.

To maintain proper airflow, blowers, hoses and filters must be monitored and inspected regularly.

- Examine a blower immediately if it begins making unusual noises.

- Monitor blower amp draws to determine if there are internal signs of wear or damage that would let the blower run at less-than-desired amp range.

- Check hoses for tight connections and holes and replace crimped or crushed hoses. Ensure that you have a system with minimal leakage points.

- Examine hose linings to detect collapses.

Filters

Air filters in resin drying systems maintain optimal airflow and stop dust and fines from contaminating the desiccant and other system components. They also ensure the desiccant is regenerated with clean ambient air.

When using desiccant beads, a plasticizer trap will stop plasticizer contamination.

Failure to maintain the filters of a resin drying system and replace them on schedule will reduce system efficiency and lead to failure of the dryer and the desiccant.

Filters can be vacuumed to remove dust and fines. If distorted or damaged, they cannot be cleaned and must be replaced.

Warm weather maintenance

In warmer months, summer humidity makes resin drying system components work harder when drying material and regenerating desiccant.

The most important aspects of a warm-weather maintenance routine are:

Resin storage

Keep resin bags sealed as long as possible. Put unused resin – particularly glass-filled nylons and some urethanes – in sealed containers to avoid long drying times. Note that some grades of nylon can take up to 16 hours to dry once the material is saturated with moisture.

Hoses

Inspect hoses for dust and other contaminants that can restrict airflow. Check for holes or leaks and insure all clamps are tightened. Properly insulation process air hose and never insulate return air hose.

Filters and filter housings

The presence of oil means a plasticizer is fouling the filters of your resin drying system. Eliminate the plasticizer contaminant by installing an aftercooler and plasticizing trap. Generally, filters can be changed every six months when drying virgin resins, and on a schedule based on appearance when drying regrind or materials with high glass content. When checking filters, also examine the housing for missing or cracked gaskets, lid fasteners and lid fit. Your maintenance schedule is dictated by the machine run time and the type of materials you are drying. When drying materials with long glass fibers, a cyclone separator might be required between the drying hopper and the dryer to maximize dust removal and stop continued blockages of the filter and dryer.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.