Why Is My Film Not White Enough?

Masterbatch-Related Causes Every Purchase Manager Must Evaluate

In today’s highly competitive plastic film market, whiteness consistency is not cosmetic—it is a commercial requirement. Poor film whiteness directly impacts customer acceptance, brand perception, export compliance, print quality, and product uniformity.

For purchase managers, exporters, and B2B decision-makers, understanding the root causes of low film whiteness is critical before attributing the issue solely to processing conditions or polymer quality. In most cases, the masterbatch formulation and its interaction with the base resin are the primary determinants of whiteness performance.

This blog explains in technical depth why your film may not be white enough and how masterbatch selection, dispersion quality, TiO₂ chemistry, and carrier compatibility play decisive roles.

Masterbatch-Related Causes Explained by Bajaj Plast Pvt. Ltd.

In the plastic film industry, whiteness is not merely an aesthetic parameter—it is a critical quality benchmark that directly influences market acceptance, printability, export approvals, and brand credibility.

At Bajaj Plast Pvt. Ltd., we work closely with purchase managers, exporters, film converters, and polymer processors who face recurring challenges related to inconsistent film whiteness, opacity loss, and shade variation.

Based on our decades of compounding expertise and application-specific R&D, this blog explains the technical masterbatch-related reasons why your film may not be achieving the desired whiteness—and how Bajaj Plast’s engineered white masterbatch solutions address these challenges.

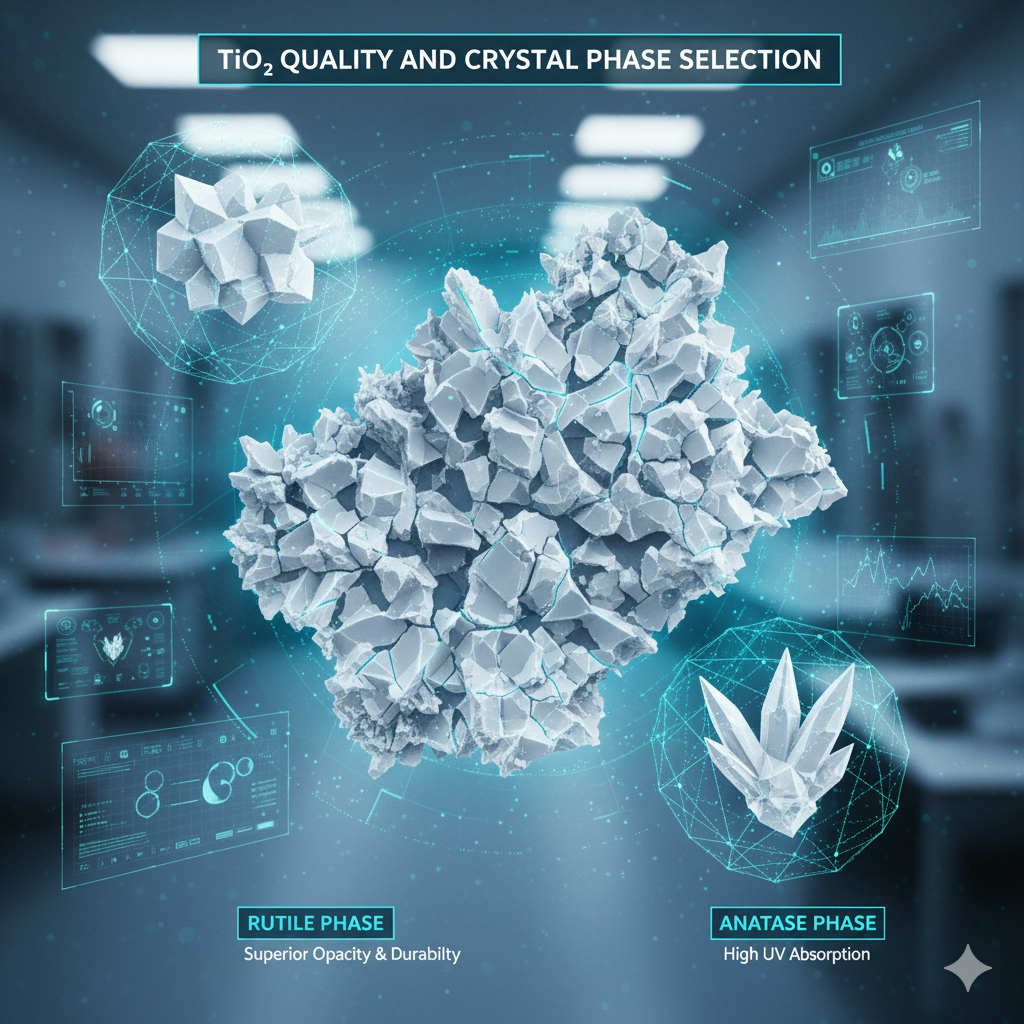

1. Inadequate TiO₂ Quality and Crystal Structure

The type and grade of Titanium Dioxide (TiO₂) used in white masterbatch formulation directly control light scattering efficiency, opacity, and brightness.

Technical Insight:

Rutile TiO₂ offers superior refractive index (~2.7) compared to Anatase, resulting in higher opacity and whiteness index.

Low-grade or mixed-phase TiO₂ reduces scattering efficiency, leading to dull or greyish films even at higher dosages.

Export-oriented films require chloride-process Rutile TiO₂ for consistent L* and b* values under spectrophotometric testing.

Purchasing Risk:

Selecting a low-cost masterbatch with inferior TiO₂ may show acceptable whiteness initially but fails under:

Thin gauge films

High output extrusion

Export quality audits

TiO₂ Quality and Crystal Phase Selection

The optical performance of a white film is fundamentally governed by the TiO₂ used in the masterbatch.

Bajaj Plast Technical Perspective:

Bajaj Plast uses chloride-process Rutile TiO₂ with a high refractive index, delivering superior light scattering and maximum opacity.

Inferior or mixed-phase TiO₂ grades compromise Whiteness Index (WI) and increase yellowness (b* value), particularly in thin films.

Export-grade applications demand consistent L and b values** under spectrophotometric evaluation—standards we strictly adhere to.

Result: Higher opacity at lower dosage with long-term shade consistency.

2. Poor TiO₂ Dispersion and Agglomeration

Whiteness is not determined by TiO₂ loading alone—dispersion quality is far more critical.

Root Cause:

Large TiO₂ agglomerates (>1 micron) reduce effective surface area

Non-uniform dispersion causes light absorption instead of reflection

Results in cloudiness, streaking, and patchy whiteness

Technical Parameters to Evaluate:

Nano or sub-micron TiO₂ dispersion

Twin-screw compounding with high shear mixing

Masterbatch rheology matching film extrusion conditions

B2B Impact:

Poor dispersion forces processors to:

Increase masterbatch dosage (cost escalation)

Compromise film thickness

Face customer rejections due to shade variation

Advanced TiO₂ Dispersion Technology

Whiteness is not defined by TiO₂ concentration alone. Dispersion quality is the real differentiator.

Bajaj Plast Advantage:

Nano-scale TiO₂ dispersion achieved through high-shear twin-screw compounding

Optimized surface treatment ensuring uniform pigment wetting

Minimal agglomeration, even at high line speeds

Why It Matters:

Poor dispersion leads to:

Light absorption instead of reflection

Streaking, cloudiness, and inconsistent film shade

Increased masterbatch consumption

Our solution: Maximum optical efficiency per micron of film thickness.

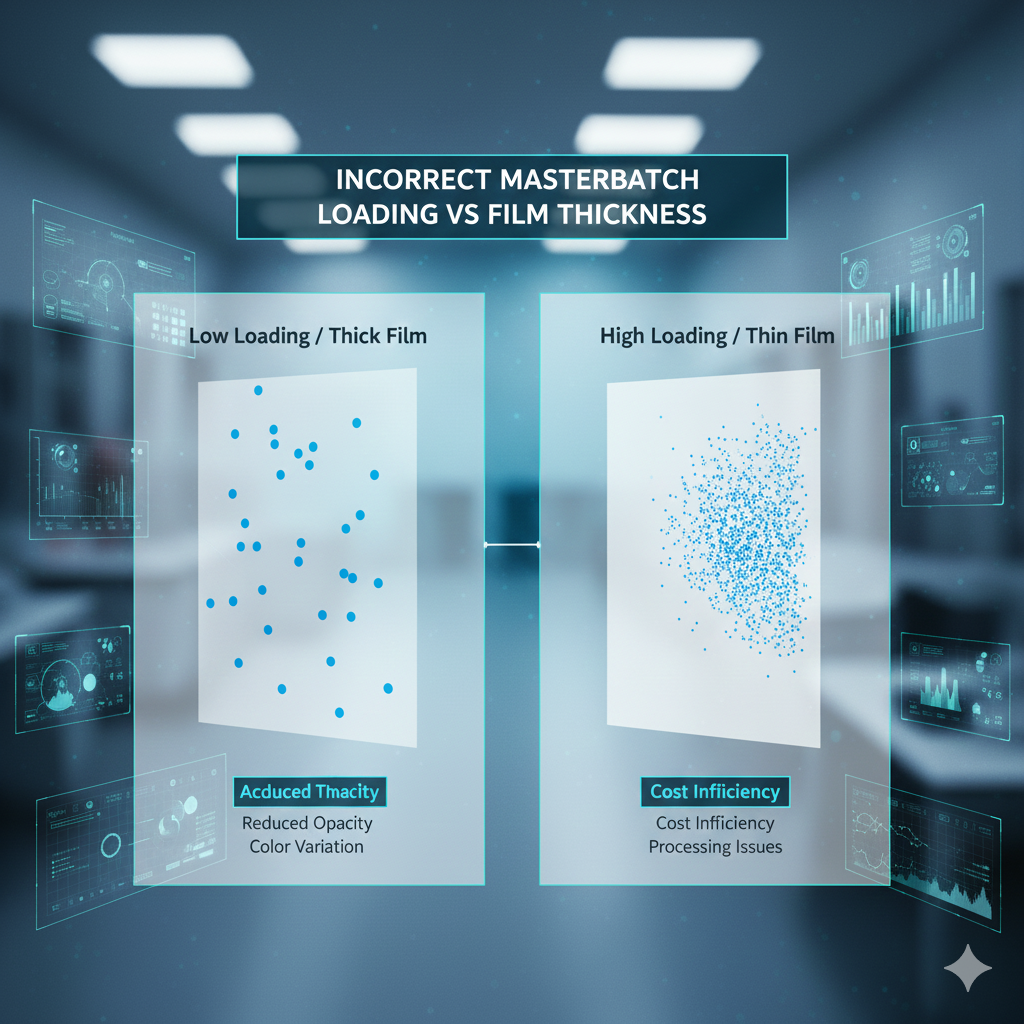

3. Incorrect Masterbatch Loading vs Film Thickness

Many purchase managers overlook the relationship between film gauge and masterbatch let-down ratio.

Technical Reality:

Thin films require higher optical efficiency per micron

Standard white masterbatch grades fail to deliver opacity below certain microns

Overloading leads to processing instability and die build-up

Professional Approach:

A technically engineered white masterbatch should:

Deliver maximum opacity at lower dosage

Maintain whiteness across varying film thicknesses

Ensure consistent haze and gloss values

Optimized Masterbatch Loading for Film Gauge

Many converters attempt to compensate for low whiteness by increasing dosage—often at the cost of processing stability..

Bajaj Plast Engineering Approach:

Our white masterbatch grades are designed specifically for thin-gauge and high-output films

High opacity is achieved without overloading, ensuring:

Stable extrusion

Reduced die build-up

Consistent film structure

This enables processors to maintain cost efficiency while meeting premium whiteness standards.

4. Carrier Resin Incompatibility with Base Polymer

A critical but often ignored factor is carrier resin mismatch

Example:

PE film using a PP-based white masterbatch

Results in phase separation and poor TiO₂ wetting

Causes micro-voids that absorb light instead of reflecting it

Technical Consequences:

Reduced optical performance

Uneven dispersion

Compromised mechanical properties

Purchasing Best Practice:

Always specify:

LLDPE/LDPE carrier for blown films

MFI compatibility with base polymer

Application-specific masterbatch grades

Carrier resin selection plays a crucial role in dispersion and optical performance.

Bajaj Plast Formulation Strategy:

LLDPE/LDPE-based carriers for blown film applications

Matched MFI for uniform melt flow and pigment distribution

Elimination of phase separation and micro-void formation

This ensures homogeneous TiO₂ distribution and superior surface finish.

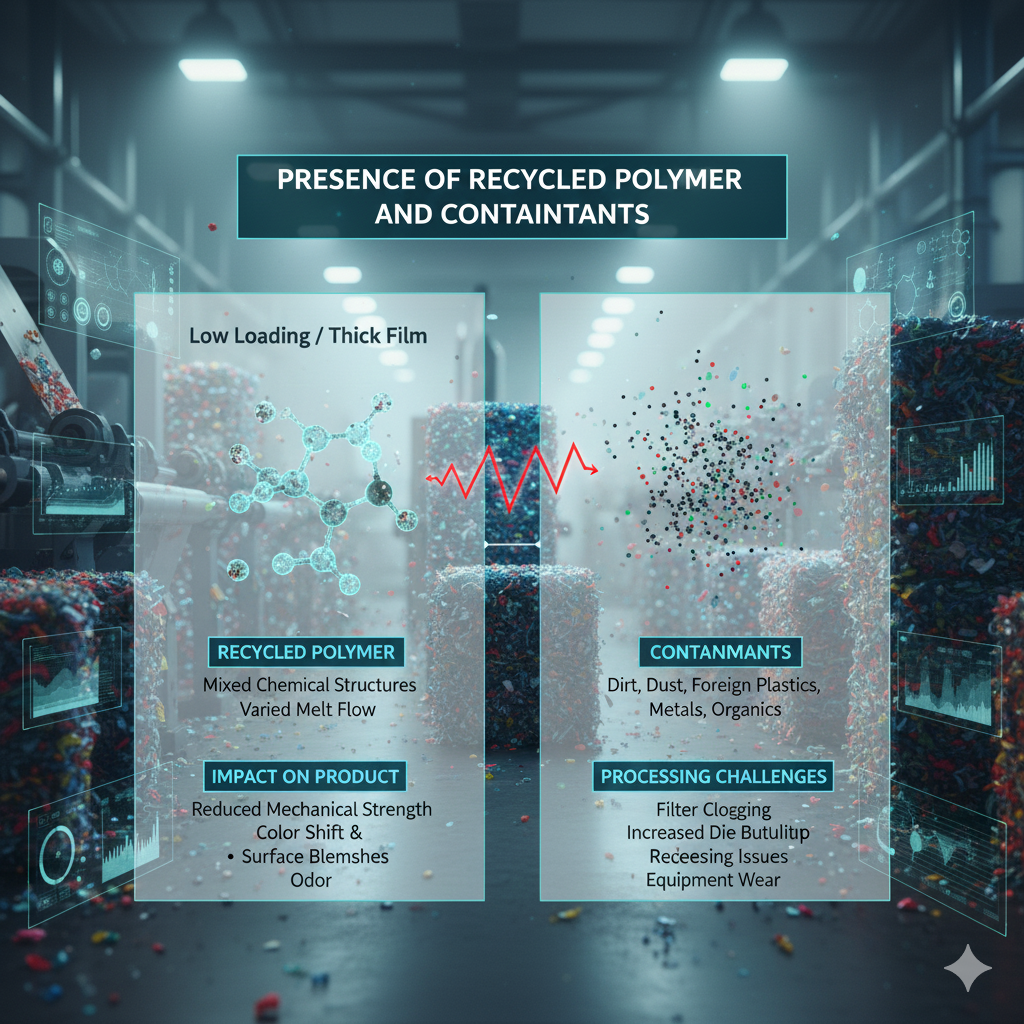

5. Presence of Recycled Polymer and Contaminants

Export-grade whiteness is extremely sensitive to:

Carbon black traces

Yellow pigments

Moisture and volatile contamination

Technical Effect:

Even 0.01% contamination can alter b* (yellow-blue axis)

Recycled polymer requires optically optimized white masterbatch

Desiccant or antioxidant synergy may be required

Commercial Risk:

Batch-to-batch shade inconsistency

Export rejection due to visual mismatch

Brand damage for packaging converters

Managing Recycled Polymer & Contamination Challenges

With increasing use of recycled polymers, maintaining whiteness has become more complex.

Bajaj Plast Solutions:

High-opacity masterbatches engineered to neutralize yellowing

Optional integration with desiccant and antioxidant masterbatch systems

Enhanced optical masking of minor contamination

Outcome: Consistent export-grade whiteness even in mixed resin streams.

6. Low Whiteness Index (WI) Masterbatch Selection

Not all white masterbatches are engineered for film applications.

Film-Grade Requirements:

High Whiteness Index (WI)

Low yellowness index (b*)

High gloss retention

Minimal impact on melt flow

Mistake to Avoid:

Using injection or blow moulding grade white masterbatch in film extrusion leads to:

Suboptimal optical output

Higher dosage requirement

Reduced processing efficiency

Application-Specific White Masterbatch Selection

Using a general-purpose white masterbatch for film applications often leads to underperformance.

Bajaj Plast Film-Grade White Masterbatch Features:

High Whiteness Index (WI)

Low yellowness index (b*)

Excellent gloss retention

Minimal impact on mechanical and sealing properties

Our grades are engineered specifically for blown film, cast film, and BOPP applications.

7. Processing Conditions Masking Masterbatch Performance

While masterbatch quality is primary, processing synergy matters.

Influencing Factors:

Excessive shear degrading TiO₂ coating

Overheating causing yellowing

Inadequate back pressure leading to poor dispersion

A technically sound masterbatch should maintain optical stability across wide processing windows, protecting processors from minor operational variations.

Processing Stability Across Operating Windows

A premium masterbatch must perform reliably across varying processing conditions.

Bajaj Plast Performance Assurance:

Thermal stability under high processing temperatures

Resistance to shear-induced degradation

Consistent dispersion under fluctuating back pressure

This provides processors with operational flexibility and reduced rejection rates.

Why Choosing the Right White Masterbatch Supplier Matters

For purchase managers and exporters, the decision is not about price per kg—it is about:

Cost per square meter of film

Consistent export quality

Reduced rejection rates

Long-term brand reliability

A premium white masterbatch delivers:

Higher opacity at lower dosage

Uniform whiteness across batches

Stable performance in high-speed extrusion lines

Compliance with international packaging standards

Why Purchase Managers Choose Bajaj Plast Pvt. Ltd.

For procurement teams and exporters, the real metric is not price per kg, but cost per finished product.

Bajaj Plast Delivers:

Higher opacity at lower let-down ratios

Reduced shade rejections

Batch-to-batch consistency

Compliance with international packaging standards

Reliable supply from multiple manufacturing units across India

Bajaj Plast white masterbatches are engineered for performance, not compromise.

Final Thoughts for B2B Decision Makers

If your film is not white enough, the problem is rarely solved by increasing dosage.

The real solution lies in scientifically engineered masterbatch formulation, correct TiO₂ selection, superior dispersion technology, and polymer compatibility.

For exporters and large-scale converters, masterbatch is not an input cost—it is a performance determinant.

Final Word from Bajaj Plast

If your film is not white enough, increasing dosage is not the solution.

The solution lies in precision-engineered masterbatch formulation, superior TiO₂ dispersion, and application-specific design.

At Bajaj Plast Pvt. Ltd., we don’t just supply white masterbatch—we engineer optical performance for global markets.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.