High-Performance Solutions for Hygiene, Medical & Industrial Packaging

Breathable Masterbatch

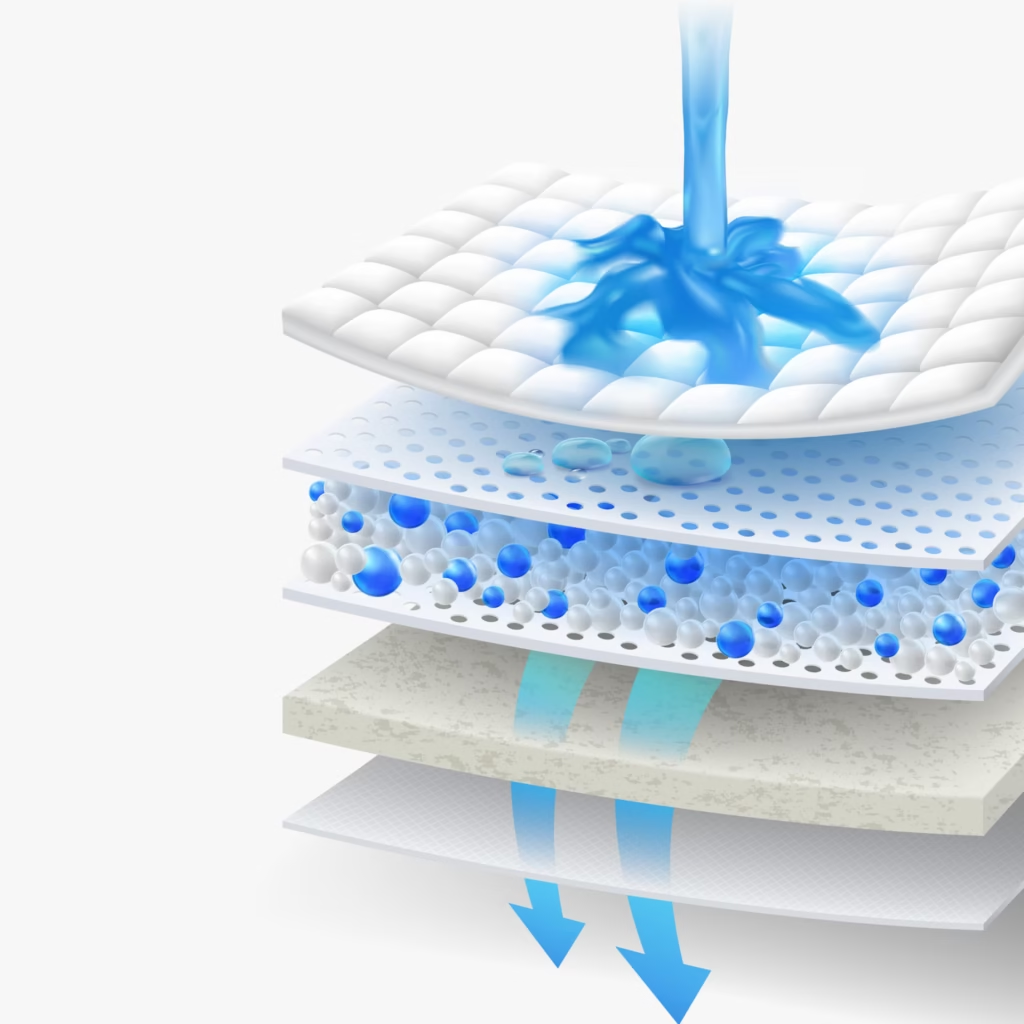

In high-value film applications where controlled air and moisture vapor transmission is critical, conventional polyolefin films fail to meet performance expectations. Breathable Masterbatch enables the production of microporous films that allow water vapor transmission while remaining liquid-water impermeable, making it an essential material for hygiene, medical, protective, and industrial applications.

At an industrial scale, breathable film performance is not determined by filler loading alone—it is governed by particle morphology, dispersion efficiency, polymer compatibility, and stretching behaviour. Our Breathable Masterbatch is precision-engineered to deliver consistent microporosity, stable processing, and export-grade performance, even in high-speed film extrusion and stretching lines.

What Is Breathable Masterbatch?

Breathable Masterbatch is a high-loading functional filler masterbatch, primarily based on specially surface-treated Calcium Carbonate (CaCO₃) dispersed in a polyolefin carrier resin (LLDPE/LDPE/PP, application-dependent).

During film stretching, the filler particles create micro-voids within the polymer matrix, forming a microporous structure that enables controlled permeability without compromising mechanical integrity.

Key Technical Performance Characteristics

▪ Controlled Microporosity Formation

Optimized CaCO₃ particle size distribution

Uniform void initiation during MD/CD stretching

Stable pore geometry across film thickness variations

▪ High Water Vapor Transmission Rate (WVTR)

Optimized Thermoregulation: Facilitates efficient moisture vapor dissipation and evaporative cooling, maintaining a stable microclimate and preventing heat accumulation.

Enhanced Skin Integrity: Promotes continuous vapor transport to prevent tissue maceration, dermatitis, and interfacial dehydration in medical and hygiene applications.

Selective Permeability: Maintains a high-performance hydraulic barrier against liquid ingress and pathogens while allowing gaseous exchange for moisture management.

Atmospheric Control: Regulates internal package humidity to prevent condensation and anaerobic spoilage, extending the shelf life of perishable goods.

▪ High Moisture Vapor Transmission Rate (MVTR)

Enables breathability without liquid leakage

Ideal for hygiene and medical packaging

Consistent MVTR values across production batches

Comparison Table for WVTR And MVTR Test

| Parameter | MVTR | WVTR |

|---|---|---|

| Accuracy | Medium | High ✅ |

| Industry Acceptance | Limited | Global standard |

| Export / Compliance | ❌ | ✔ Yes |

| Suitable for Barrier Films | ❌ | ✔ Yes |

| Preferred by Buyers | ❌ | ✔ Yes |

▪ Excellent Dispersion & Process Stability

High-shear compounded for uniform filler distribution

Minimal agglomeration and die build-up

Smooth film surface with reduced pin-holing risk

Typical Applications of Breathable Masterbatch

Breathable Masterbatch is widely used in high-growth, export-oriented industries, including:

Baby diapers & adult incontinence products

Sanitary napkins & feminine hygiene products

Medical gowns, drapes & protective wear

Surgical packaging & sterilizable wraps

Industrial protective laminates

Agro – textile & specialty membrane films

Advantages for Purchase Managers & Exporters

For procurement and export teams, breathable masterbatch performance directly impacts cost efficiency, product compliance, and customer satisfaction.

Commercial & Operational Benefits:

Higher breathability at optimized dosage levels

Reduced film rejection due to uniform pore structure

Compatibility with high-speed blown & cast film lines

Consistent quality suitable for global supply chains

Lower cost per square meter of breathable film

Technical Formulation Excellence

▪ Filler Engineering

High-purity CaCO₃ with controlled aspect ratio

Surface-modified for improved polymer wetting

Reduced impact on tensile strength after stretching

▪ Carrier Resin Compatibility

Available in LLDPE, LDPE & PP carrier systems

MFI matched to base polymer for uniform melt flow

Ensures consistent dispersion during extrusion

▪ Stretching Performance

Designed for mono-axial and bi-axial stretching

Stable pore development without film tearing

Maintains mechanical balance post-orientation

Processing Compatibility

Our Breathable Masterbatch is compatible with:

- Blown film extrusion lines

- Cast film extrusion systems

- Inline & offline stretching units

- Multilayer film structures (as core or functional layer)

Processing windows are optimized to ensure consistent microporous formation without sacrificing line productivity.

Quality & Export Compliance

For exporters and global brands, consistency is non-negotiable.

Our Breathable Masterbatch is manufactured under:

Strict raw material selection protocols

Batch-to-batch consistency controls

Internal quality validation for dispersion & pore formation

Compliance with international hygiene & packaging norms (application-dependent)

Why Choose Our Breathable Masterbatch?

Engineered for high breathability with mechanical integrity

Proven performance in hygiene & medical applications

Optimized for cost efficiency and process stability

Suitable for large-scale export production

Backed by technical support & application guidance

Final Note for B2B Decision Makers

Breathable film manufacturing is not a trial-and-error process—it is a precision-driven technology. The right breathable masterbatch determines pore uniformity, WVTR consistency, and long-term product reliability.

Our Breathable Masterbatch is designed to help film manufacturers, exporters, and global suppliers achieve consistent breathable performance at industrial scale, without compromising productivity or quality.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.