1. What Is Recycled Polypropylene?

Recycled polypropylene plays a crucial role in reducing plastic waste and promoting sustainability. Understanding how polypropylene (PP) is recycled can help businesses and consumers make more eco-friendly choices. Let’s explore the recycling process, benefits, and challenges of recycled polypropylene.

1.1. Definition of Recycled Polypropylene

Recycled polypropylene refers to polypropylene plastic that has been processed and reused instead of being discarded. It is commonly used in various industries, including packaging, automotive, and textiles.

1.2. Why Is It Important to Recycle Polypropylene?

PP is one of the most widely used plastics, but its disposal poses environmental risks. Recycling reduces plastic waste, conserves resources, and minimizes pollution.

Recycled polypropylene refers to polypropylene plastic that has been processed and reused instead of being discarded.

2. The Process of Recycling Polypropylene

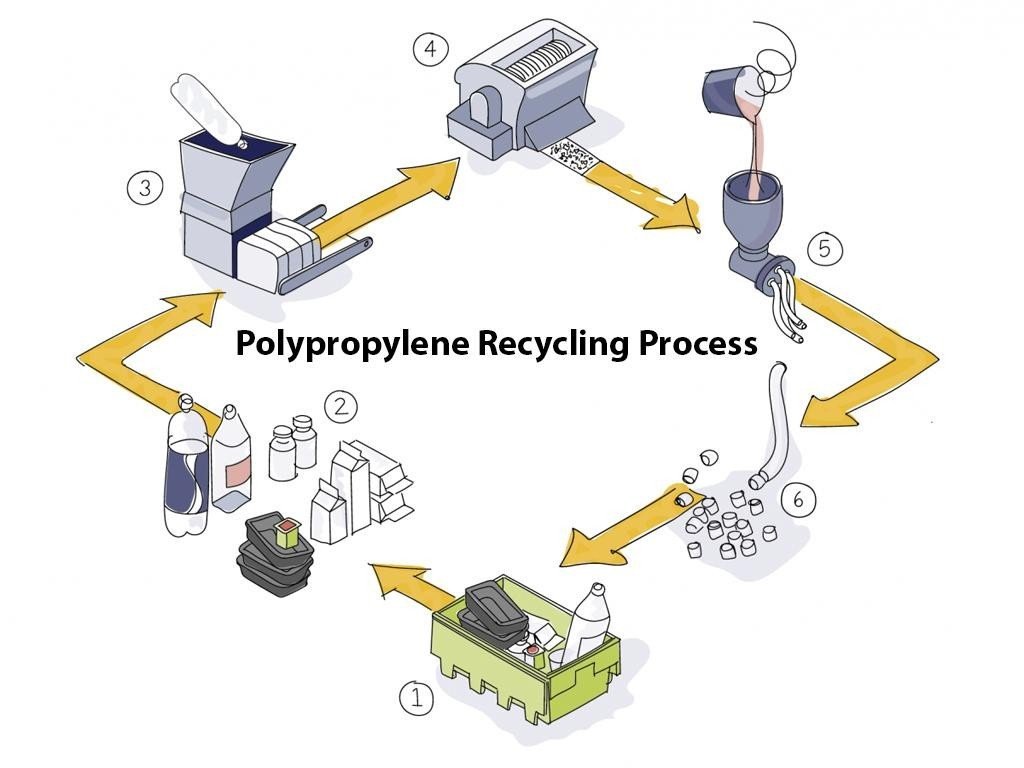

2.1. Collection and Sorting

Used PP products, such as packaging and containers, are collected from households and industries. These materials are sorted based on color, type, and contamination levels.

2.2. Cleaning and Shredding

The sorted plastics are cleaned to remove dirt, labels, and other contaminants. They are then shredded into small flakes for further processing.

2.3. Melting and Reprocessing

The shredded polypropylene is melted at high temperatures and reformed into pellets. These pellets serve as raw materials for manufacturing new plastic products.

2.4. Quality Testing and Manufacturing

Recycled PP undergoes quality testing to ensure it meets industry standards before being used in various applications, such as packaging, automotive parts, and household goods.

3. Benefits of Recycled Polypropylene

3.1. Environmental Benefits

Recycling PP reduces landfill waste, conserves fossil fuels, and lowers carbon emissions, contributing to a healthier planet.

3.2. Cost-Effectiveness

Recycled PP is often more affordable than virgin polypropylene, helping manufacturers reduce production costs while maintaining quality.

3.3. Energy Efficiency

Producing recycled polypropylene requires less energy compared to manufacturing virgin plastic, making it a sustainable alternative.

3.4. Versatility in Applications

Recycled PP is used in packaging, textiles, automotive components, and construction materials, showcasing its adaptability.

Recycled PP is used in packaging, textiles, automotive components, and construction materials, showcasing its adaptability.

4. Challenges in Recycling Polypropylene

4.1. Contamination Issues

PP recycling faces challenges with contamination from food residues, labels, and mixed plastics, which can affect the quality of recycled materials.

4.2. Limited Recycling Infrastructure

Many regions lack proper recycling facilities, making it difficult to recycle polypropylene efficiently.

4.3. Quality Degradation

Recycled PP may lose some mechanical properties after multiple recycling cycles, limiting its applications in high-performance products.

5. Innovations in Polypropylene Recycling

5.1. Advanced Sorting Technologies

New optical sorting systems and AI-driven techniques improve the accuracy of PP recycling, reducing contamination levels.

5.2. Chemical Recycling Methods

Unlike traditional mechanical recycling, chemical recycling breaks PP down to its molecular level, allowing for higher-quality recycled materials.

5.3. Biodegradable Polypropylene Alternatives

Research is ongoing to develop bio-based or biodegradable polypropylene alternatives to further enhance sustainability.

6. How Consumers Can Support Polypropylene Recycling

6.1. Proper Disposal Practices

Consumers should rinse and clean PP containers before recycling to prevent contamination and improve recycling efficiency.

6.2. Choosing Recyclable Packaging

Opting for products with recyclable PP packaging supports the recycling industry and reduces plastic waste.

6.3. Supporting Brands Using Recycled PP

Purchasing products made from recycled polypropylene encourages companies to invest in sustainable materials.

7. Conclusion

Recycled polypropylene is an essential solution for reducing plastic waste and promoting sustainability. By understanding the recycling process and supporting eco-friendly practices, businesses and consumers can contribute to a greener future. With ongoing innovations, the recycling of polypropylene will continue to improve, making it a more sustainable option for various industries.

8. About Bajaj Plast PP base Masterbatches

As a trusted manufacturer of high-quality plastics, Bajaj Plast is dedicated to providing customers with premium PP products that enhance factory efficiency and boost market competitiveness.

Our range of PP products includes:

Bajaj Plast PP Base Color Masterbatches :

Bajaj Plast PP Base Additves:

1.Bajaj Plast Odour removal mb

4. Bajaj Plast Optical Brightener

5.Bajaj Plast PPA Polymer processing aid

Bajaj Plast PP Base TIO2 White masterbatch

Bajaj Plast PP Base Filler Masterbatches :

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.