High-Performance Masterbatches for Mulch Films

Mulch Film

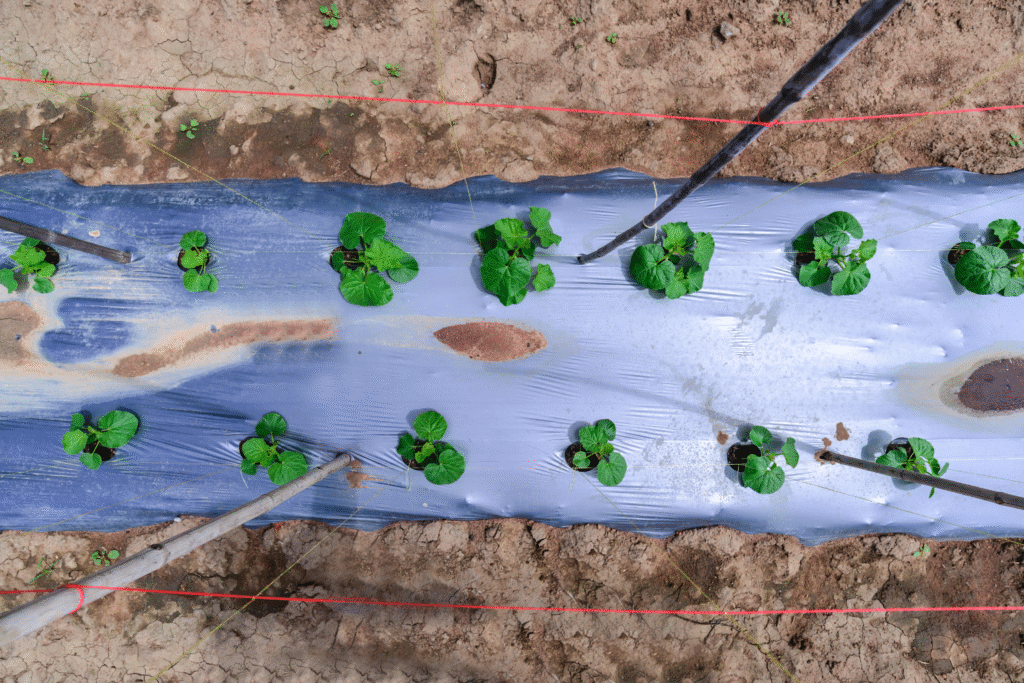

Mulch film is a specialized agricultural polymer film, predominantly manufactured from LDPE, LLDPE, mLLDPE, or biodegradable polymer blends, engineered to modify the soil micro-climate and enhance crop productivity. It acts as a soil cover layer that controls moisture evaporation, regulates temperature, minimizes weed growth, and optimizes nutrient utilization.

In modern precision agriculture, mulch films are considered a high-value agri-input, directly influencing early germination, higher yield, water conservation, and improved fertilizer efficiency.

Importance of Mulch Film in Today’s Agri Market

With rising demand for high-efficiency farming inputs, mulch film has become an indispensable agro-polymer product due to the following market drivers:

Increasing water scarcity → Higher need for moisture retention solutions

Shift toward precision farming → Controlled soil environment

Rising demand for plasticulture applications

Higher crop yields per acre requirement

Adoption of drip irrigation + mulch film combinations

The global mulch film market is expanding rapidly due to its impact on crop quality, uniform size, and faster maturity cycles, making it essential for horticulture, floriculture, fruit farming, and vegetable cultivation.

How Mulch Film Is Manufactured

Mulch film is produced using Blown Film Extrusion Technology with precise polymer–additive balance. The typical process includes:

1. Resin Selection

LDPE / LLDPE / mLLDPE for general mulch film

EVA blends for cold-weather flexibility

Biodegradable polymers (PLA/PBAT/Corn-starch blends) for eco-certified mulch films

2. Compounding & Additive Integration

Masterbatches are incorporated to provide:

UV stability

Thermal stability

Coloration (Black/Silver)

Anti-block, slip, and processing improvement

3. Blown Film Extrusion

Melt homogenization

Controlled bubble stability

Precise gauge control (15–50 microns)

Surface finish optimization

Uses & Applications of Mulch Film

Mulch films are used across a vast range of agricultural segments:

Primary Applications

Vegetable cultivation (tomato, capsicum, chili, cucumber)

Fruit plantations (strawberry, watermelon, banana)

Floriculture (rose, chrysanthemum, gerbera)

Medicinal & aromatic plants

Greenhouse farming

Functional Benefits

Soil temperature regulation

Moisture conservation

Weed suppression

Reduced fertilizer leaching

Pest prevention

Cleaner & improved crop quality

Faster harvesting cycles

Types of Mulch Films

Depending on the agronomic requirement, mulch films are offered in multiple engineered versions:

1. Black Mulch Film

Weed control

Soil warming

UV durability

Masterbatch used: Black Masterbatch, UV Stabilizer MB, Processing Aid MB

2. Silver–Black Mulch Film

Reflects sunlight → repels pests

Maintains cooler surface

Used in high-temperature zones

Masterbatch used: Metallic Silver MB, UV MB, Slip MB, Anti-block MB

3. White–Black Mulch Film

Cooler soil conditions

Suitable for summer vegetables

Masterbatch used: White Tio2 MB, UV MB, Slip MB

4. Biodegradable Mulch Film

Sustainable alternative

PLA/PBAT based

Certified compostable

Masterbatch used: Biodegradable Color MB, Anti-oxidant MB

5. Perforated Mulch Film

Pre-punched for direct planting

Masterbatch used: UV MB, Slip MB

Why Masterbatches Are Critical for Mulch Film Manufacturing

Mulch film runs in severe outdoor conditions—high UV exposure, fluctuating temperatures, chemical fertilizers, soil moisture, and mechanical stress during installation. Hence, high-performance masterbatches are essential for film longevity, mechanical strength, and functional performance.

Key Reasons Masterbatches Are Needed in Mulch Film:

1. UV Stability & Weather Resistance

Mulch films are exposed to:

High UV Index

Ozone degradation

Temperature fluctuations

A UV Stabilizer Masterbatch ensures:

Prevents polymer chain scission

Extends film life (6–18 months)

Maintains mechanical strength

2. Color Performance (Black / Silver / White)

Black Masterbatch ensures complete opacity & weed suppression

Silver MB gives pest repellent reflectivity

TiO₂ White MB provides thermal balance in hot climates

3. Mechanical Strength & Puncture Resistance

Processing Aid MB enhances melt flow and bubble stability

Anti-oxidant MB prevents degradation during melt processing

4. Surface Properties

Slip MB: reduces coefficient of friction

Anti-block MB: smooth unwinding

Thermic MB: controls NIR absorption for soil warming

5. Process Optimization

Enables thinner gauge films (15–20 microns)

Reduces breakage during installation

Improves extruder output

Why Our Masterbatches for Mulch Film Are the Preferred Choice

Our masterbatches are formulated with agriculture-grade stabilizers engineered for long-term field exposure. Key advantages include:

High Agricultural UV Stabilizers (UVA + HALS Technology)

Provides consistent film life across diverse climatic zones.

Premium Carbon Black & TiO₂ Pigment Loading

Delivers strong opacity and spectral properties for weed control & thermal management.

Optimized Additive Synergy

UV + AO + Slip + Anti-block engineered for high-performance blown film lines.

Excellent Dispersibility

Ensures smooth processing, strong mechanical properties, and high tear resistance.

Film Life Customization

Available for 3 months, 6 months, 12 months, 18 months performance grades.

Compatible with LDPE/LLDPE/mLLDPE Blends

Provides consistent extrusion stability on high-speed lines.

Masterbatches Used in Mulch Film Manufacturing

Our range includes:

1. Bajaj Plast UV Stabilizer Masterbatch

Prevents outdoor degradation

(Highly recommended for all mulch films)

2. Bajaj Plast Black Masterbatch 40–50% Carbon Black

For black mulch films

Enhances opacity & soil heating

3. Bajaj Plast Silver Masterbatch

For silver–black mulch

Reflects light & repels insects

4. Bajaj Plast White TiO₂ Masterbatch

For white–black mulch

Improves thermal insulation

5. Bajaj Plast Slip and Anti-block Masterbatch

Controls COF for easy laying & handling

Improves roll opening & handling

6. Bajaj Plast Processing Aid / PPA MB

Ensures stable bubble, reduces melt fracture

7. Bajaj Plast Biodegradable Filler Masterbatch

For PLA/PBAT-based compostable mulch films

Conclusion

Mulch film has evolved into a mission-critical agri-polymer product, driving efficiency, sustainability, and profitability across modern farming systems. Its ability to modify the soil environment, enhance input utilization, and significantly boost crop yields makes it indispensable for high-value agriculture. However, the true performance, durability, and reliability of mulch films depend heavily on the quality of masterbatches integrated during production. From UV stabilization and thermal regulation to surface optimization and mechanical reinforcement, each masterbatch plays a pivotal role in enabling films to withstand harsh outdoor conditions while maintaining structural integrity throughout the crop cycle.

For manufacturers targeting consistent film life, superior field performance, and high extrusion efficiency, choosing the right masterbatches is not just an additive decision—it is a strategic technical advantage. With advanced formulations, optimized dispersibility, and application-specific stabilizers, our masterbatches empower processors to deliver high-strength, climate-resilient, and agronomically effective mulch films that meet the growing demands of the global agricultural market.

Mulch film will continue to be a cornerstone of plasticulture, and high-performance masterbatches will remain the foundation that ensures its long-term value, reliability, and competitiveness.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.