Bajaj UV Stabilizer Masterbatches for

Outdoor Polymer

Outdoor plastic products operate in the harshest environmental conditions—continuous UV radiation, thermal cycles, humidity, and oxidative stress. Without adequate stabilization, polymer chains undergo photodegradation, leading to discoloration, embrittlement, cracking, and premature mechanical failure. This is where UV Stabilizer Masterbatches play a mission-critical role.

UV Stabilizer

UV Stabilizer Masterbatches are highly engineered additive concentrates containing Hindered Amine Light Stabilizers (HALS), UV Absorbers (UVA), Quenchers, and Antioxidant Systems dispersed in a compatible polymer carrier.

They function as photoprotection systems by:

Absorbing harmful UV radiation (290–400 nm) before it penetrates the polymer matrix

Neutralizing free radicals formed during UV exposure

Stabilizing polymer chains against photolytic cleavage

Delaying oxidation and thermal aging

Extending product life, especially under continuous sunlight exposure

A well-designed UV masterbatch provides long-term stabilization up to 5+ years outdoors, depending on dosage and application.

Why UV Stabilizer Masterbatches Are Essential in Outdoor Plastic Applications

Outdoor plastics are continuously exposed to:

High UV Index

Moisture & humidity cycles

Temperature extremes

Oxidation

Mechanical stress

This combination dramatically accelerates degradation in unprotected polymers such as PE, PP and HDPE.

Key Advantages of UV Stabilizer Masterbatch:

✔ Enhances service life and durability

✔ Controls color fading and maintains visual aesthetics

✔ Prevents micro-cracking & embrittlement

✔ Keeps mechanical properties stable (tensile strength, impact strength)

✔ Improves weatherability & outdoor performance

✔ Reduces field failures, replacements, and warranty claims

✔ Ensures compliance with industry performance specs for outdoor products

For purchase managers and OEMs, incorporating UV stabilizers is not optional—it’s a protection protocol for product quality, customer satisfaction, and brand reliability.

How UV Stabilizer Masterbatches Are Manufactured

The formulation of UV masterbatch requires precision compounding using:

1. HALS (Hindered Amine Light Stabilizers)

Acts as a radical scavenger, providing long-term stabilization.

2. UV Absorbers (UVA)

Absorbs UV radiation and converts it into harmless thermal energy.

3. Antioxidants (Primary & Secondary)

Controls oxidative degradation during both processing & lifetime.

4. Polymer Carrier Resins

Typically LLDPE, LDPE, HDPE, PP depending on application compatibility.

5. High-shear twin-screw extruders

Used to ensure consistent dispersion and optimum polymer-additive interaction.

Result: A high-performance additive concentrate engineered for outdoor endurance.

Why Our UV Stabilizer Masterbatches for Outdoor Plastic Applications

We engineer UV masterbatches designed specifically for harsh climatic conditions, high UV zones, and material-specific degradation patterns.

Our UV Stabilizer Masterbatches are designed to provide:

Long-term UV protection (2–10 years depending on grade & dosage)

Optimized HALS + UVA synergy for superior weatherability

Excellent thermal stability during extrusion and moulding

High dispersion for consistent performance

Compatibility with all polyolefin-based products

Custom solutions for unique outdoor applications

Cost-effective formulations without compromising durability

We ensure performance, consistency, and regulatory compliance, making our products ideal for export-grade and domestic outdoor applications.

Importance of Outdoor Plastic Applications in Today’s Market

Outdoor plastics are essential across infrastructure, agriculture, water management, logistics, household products, and industrial packaging. With increasing UV radiation levels and global climate variability, the demand for UV-stabilized outdoor plastics is rapidly growing.

Industries Highly Dependent on UV Protection:

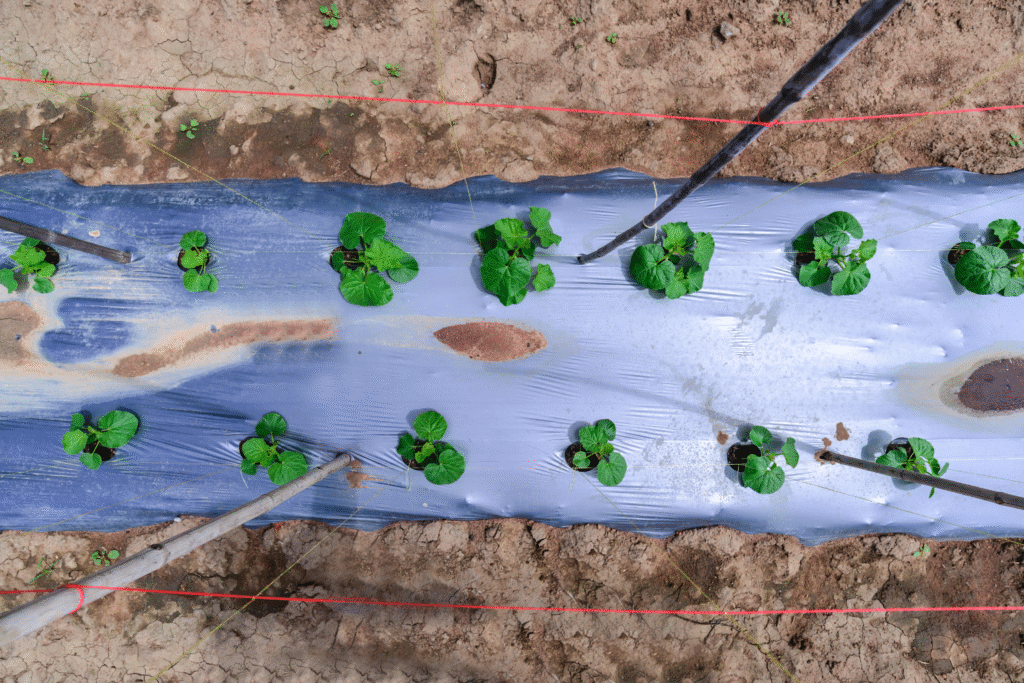

Agriculture

Mulch films

Greenhouse films

Shade nets

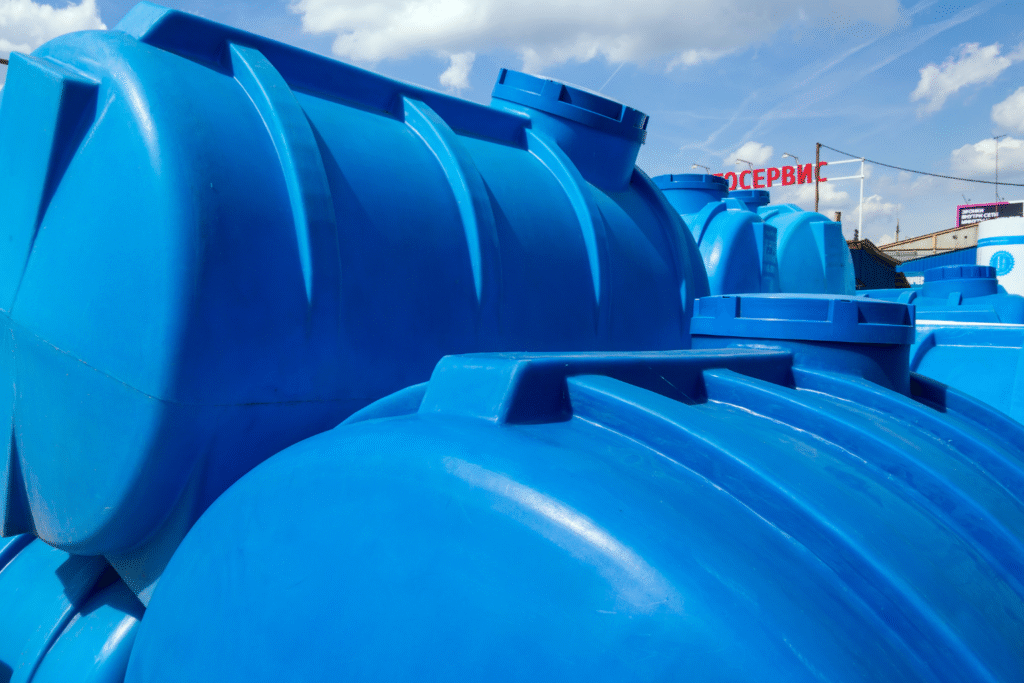

Water storage

HDPE tanks

Drums

Barrels

Rigid packaging

Jerry cans

Crates

Industrial containers

Logistics & warehousing

FIBC jumbo bags

Woven sacks

Tarpaulines

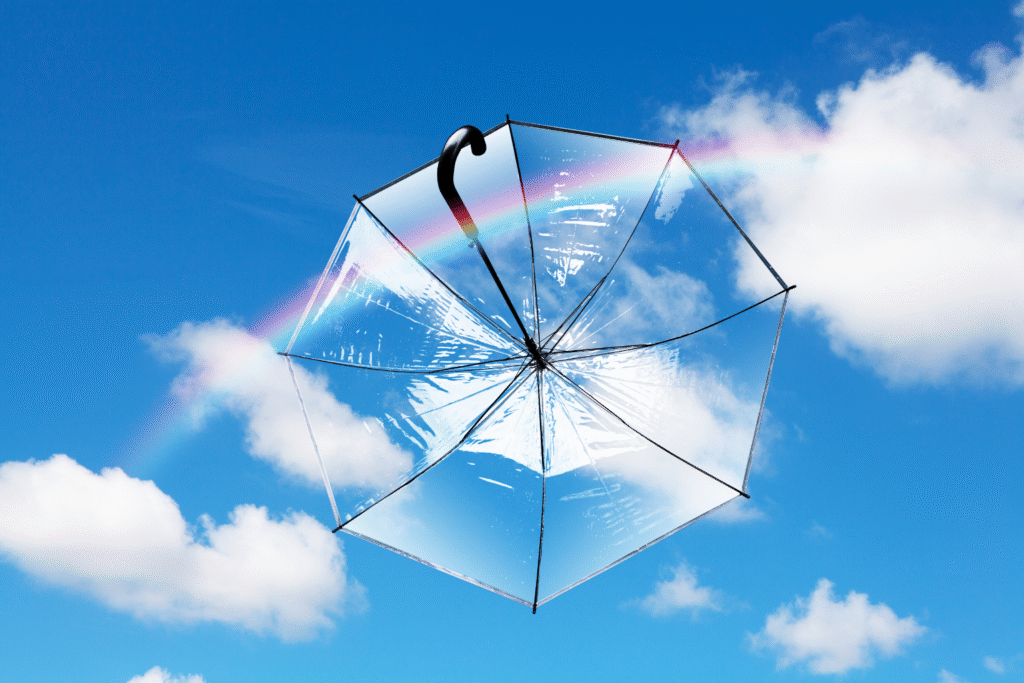

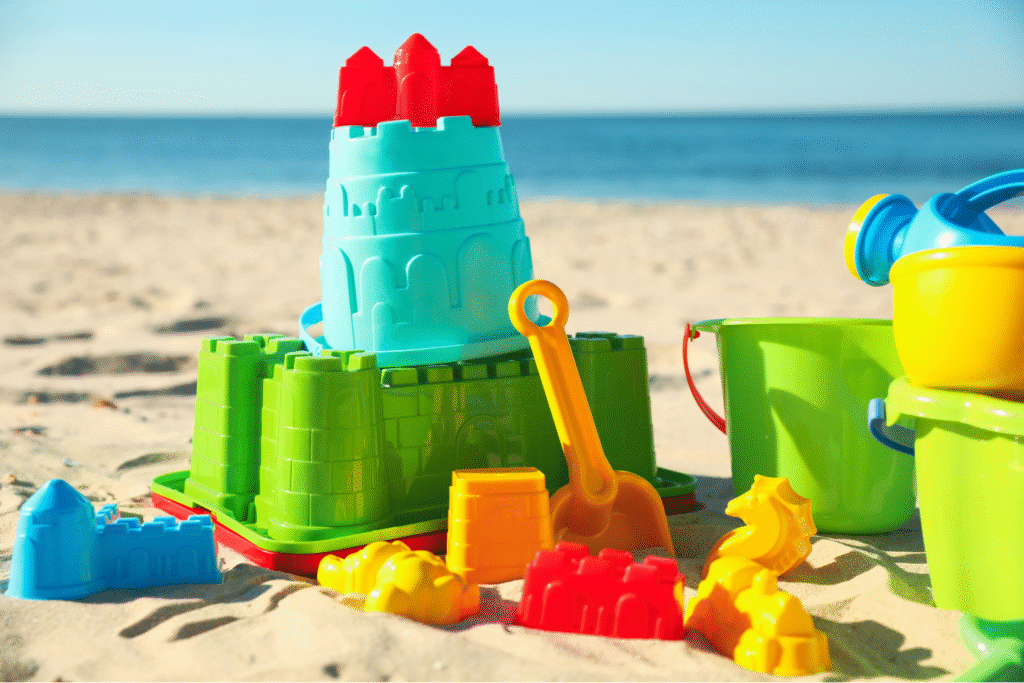

Outdoor household products

Toys

Play rides

Garbage Bins

Construction

Pipes

Geo Membranes

Roofing sheets

Automotive

Dashboards

Sunroofs

Headlights

Plastic Furniture

Chairs

Stools

Tables

Must Requiring UV Stabilization Outdoor Plastic Products

Below are major outdoor applications where UV Stabilizer Masterbatches are indispensable:

1. Tarpaulins (HDPE/LDPE)

Used in agriculture, construction, transport covers, and temporary shelters.

UV stabilizers prevent tearing, chalking, brittleness, and loss of tensile strength.

2. Woven Sacks (PP)

Used for fertilizer, grains, cement, polymer packaging.

UV masterbatches prevent yarn weakening, fading, and splitting under sunlight.

3. FIBC Jumbo / Bulk Bags

Used for cement, chemicals, minerals, food products.

UV stabilizers protect load-bearing strength and ensure long-term outdoor storage stability.

4. Drums & Barrels (HDPE)

Used for chemical storage, industrial packaging.

UV stabilization prevents stress cracking, color fading, and brittleness.

5. Water Tanks (HDPE / LLDPE)

Outdoor tanks are directly exposed to UV for years.

UV stabilizers ensure long service life, prevent UV cracks, and maintain tank integrity.

6. Jerry Cans (HDPE)

Used in petroleum, lubricants, chemicals.

UV protection helps maintain structural strength and color performance.

7. Outdoor Plastic Furniture

Stools, tables, chairs, and kindergarten play rides require high UV performance to avoid:

Color fading

Brittleness

Micro-cracking

Loss of mechanical strength

7. Nursery Greenhouses

Conclusion

In the competitive world of outdoor plastic manufacturing, UV Stabilizer Masterbatches are not an additive—they are a performance necessity. They ensure that outdoor plastic products retain:

Mechanical integrity

Color stability

Weather resistance

Long-term service life

Market acceptability

For purchase managers, OEMs, and industrial decision-makers, selecting a high-performance UV masterbatch directly influences product quality, durability, and brand reputation. With rising UV radiation and increasing outdoor applications, UV stabilization is a strategic investment in quality and longevity.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.