Masterbatch Quality Parameters Every Purchase Manager Must Check

(Technical Guide for Smart Procurement)

In the plastics industry, masterbatch is not just an additive—it is a critical raw material that directly influences product appearance, processing stability, mechanical performance, rejection rate, and final customer satisfaction.

For purchase managers, selecting masterbatch based only on price per kg is a risky strategy. A cheaper masterbatch can cause poor dispersion, shade variation, processing downtime, filter choking, extrusion instability, and high scrap generation, ultimately increasing total production cost.

This technical guide explains the most important masterbatch quality parameters every procurement professional must verify before finalizing any supplier.

Why Quality Parameters Matter More Than Price

Many purchase decisions fail because procurement teams focus only on:

Cost per kg

Shade card approval

Supplier promises

But the real performance of masterbatch is determined by its:

dispersion quality

pigment concentration consistency

thermal stability

compatibility with base polymer

processing cleanliness

A masterbatch that saves ₹10/kg but increases rejection by 2% can cost lakhs in losses.

Top Masterbatch Quality Parameters Every Purchase Manager Must Check

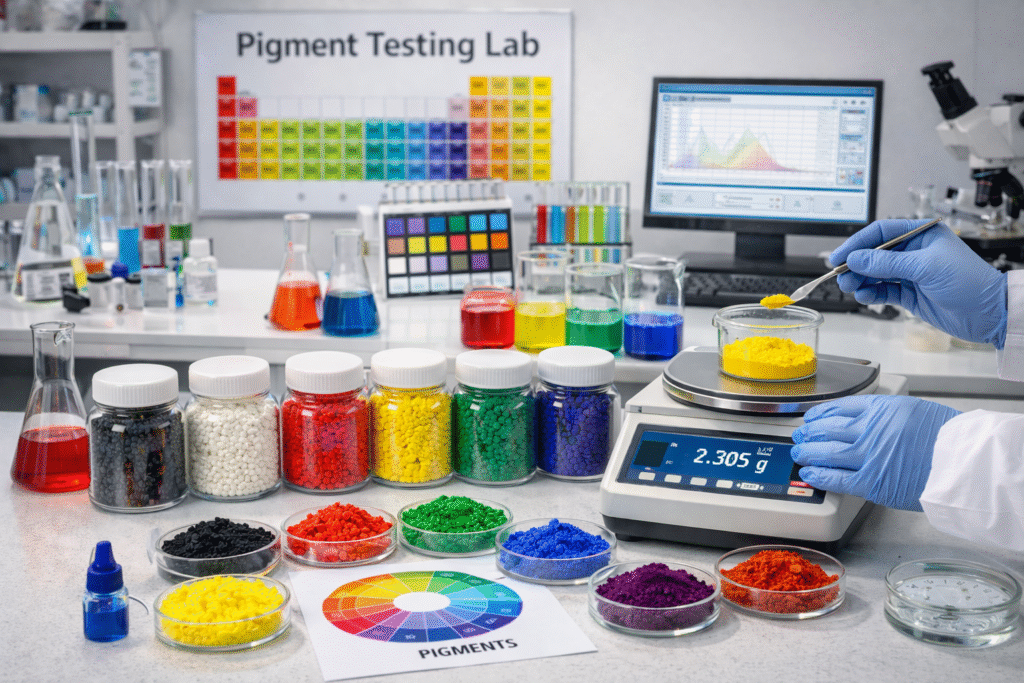

1. Pigment / Additive Loading Percentage (Active Content)

One of the most important masterbatch parameters is active ingredient percentage, commonly called loading.

What to Check:

Pigment content (%)

Additive content (%)

Standard deviation across batches

Why It Matters:

If loading fluctuates, your production will face:

Shade inconsistency

Variable dosing requirement

Overconsumption of masterbatch

Higher production cost per kg of finished product

Ideal Expectation:

A professional supplier maintains:

±0.5% batch-to-batch loading variation for high-end applications.

2. Melt Flow Index (MFI) of Masterbatch

MFI is a key indicator of flow behavior and processing compatibility.

What to Check:

Masterbatch MFI @ standard test conditions

Compare with base polymer MFI

Why It Matters:

If masterbatch MFI is too low compared to polymer:

poor mixing

high torque load

improper dispersion

streaking and specks

If masterbatch MFI is too high:

polymer viscosity imbalance

weak mechanical properties

film breakage risk

Recommended Practice:

Procurement must ensure masterbatch MFI is within acceptable processing range.

Example:

For LDPE film extrusion base polymer MFI 2.0, masterbatch should ideally be between 2 to 8 depending on pigment type.

3. Dispersion Rating (Most Critical for Film & Molding Applications)

Dispersion is the ability of pigment/additive particles to spread uniformly in the polymer matrix.

What to Check:

Dispersion test report

Microscopic evaluation (DIN / ISO)

Filter mesh residue test

Why It Matters:

Poor dispersion causes:

black spots

color streaking

surface roughness

die lines in film

weak mechanical strength

Technical Standards:

Dispersion is typically evaluated by:

DIN 55986

ISO 18553

Microscopic dispersion grading

Purchase Tip:

Ask supplier for dispersion grading report such as:

Grade 1 (Excellent)

Grade 2 (Good)

Grade 3 (Average)

Grade 4 (Reject)

For premium B2B supply chain, Grade 1 or Grade 2 is mandatory.

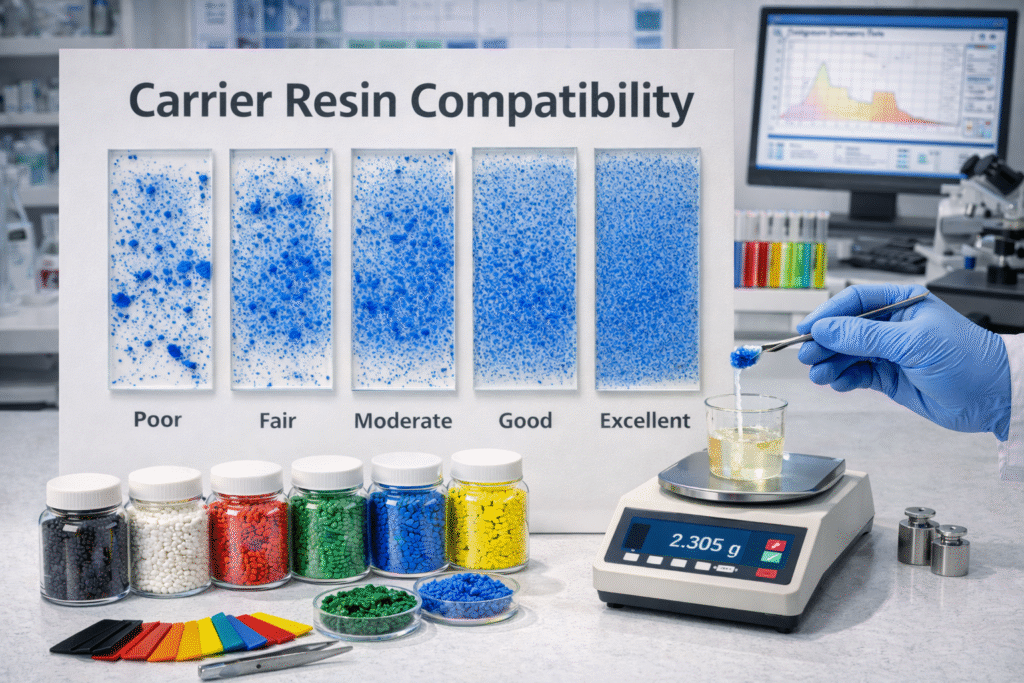

4. Carrier Resin Compatibility

Masterbatch performance depends heavily on its carrier resin.

What to Check:

Carrier resin type (LDPE, LLDPE, PP, EVA, PS, ABS etc.)

Compatibility with your base polymer

Melt blending behavior

Why It Matters:

Wrong carrier causes:

poor bonding

migration issues

surface blooming

weak tensile properties

processing instability

Example:

Using LDPE-based masterbatch in PP injection molding can lead to:

reduced stiffness

shrinkage mismatch

warpage

poor dispersion

5. Moisture Content (Critical for Film & Engineering Plastics)

Moisture is a hidden defect that can destroy processing.

What to Check:

Moisture % in masterbatch (Karl Fischer test)

Storage packaging quality

Why It Matters:

High moisture leads to:

bubble formation

voids in injection molded parts

film pinholes

surface haze

hydrolytic degradation

Acceptable Range:

Standard polyolefin masterbatch: <0.1%

Engineering polymer masterbatch: <0.05%

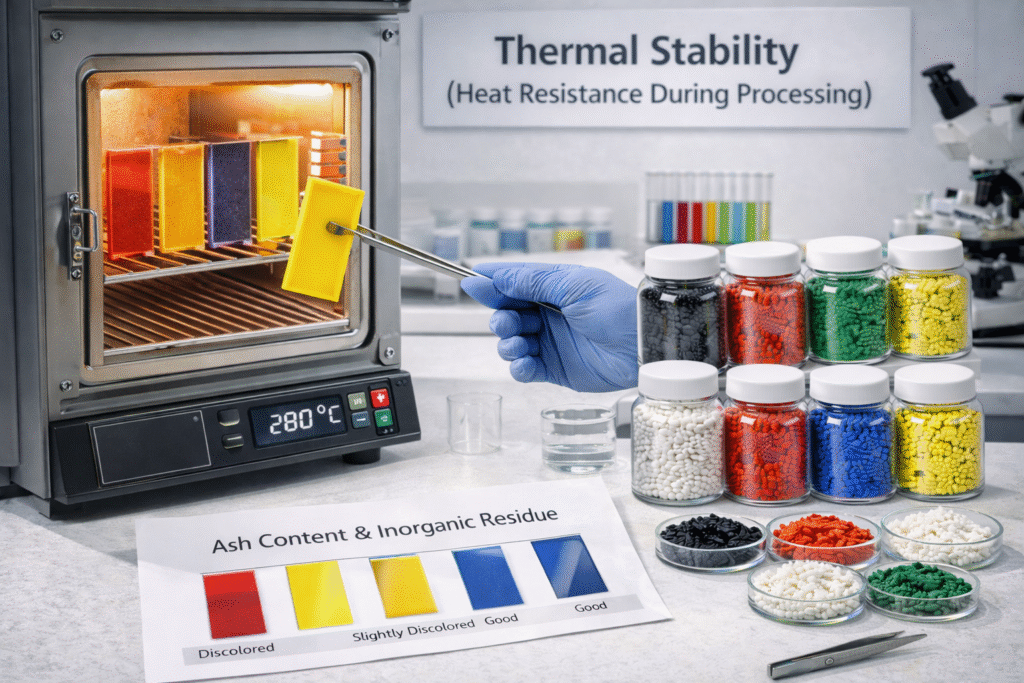

6. Ash Content & Inorganic Residue

Moisture is a hidden defect that can destroy processing.

fillers

pigment residue

silica contamination

calcium carbonate excess

What to Check:

Ash content test (at 550°C)

Inorganic contamination %

Why It Matters:

High ash causes:

filter choking in film extrusion

die buildup

poor gloss

higher brittleness

screw and barrel wear

For high-quality masterbatch, ash content should remain stable batch-to-batch.

7. Thermal Stability (Heat Resistance During Processing)

Many pigments and additives degrade at high processing temperatures.

What to Check:

Thermal stability test report

Color shift at processing temperature

Plate-out resistance

Why It Matters:

If masterbatch is not thermally stable:

shade changes during long runs

burnt specks appear

odor generation

yellowing

Applications Where Thermal Stability is Mandatory:

blow molding

BOPP

raffia tapes

extrusion coating

automotive parts

Purchase managers must ask:

“Is the pigment stable at 250°C continuous?”

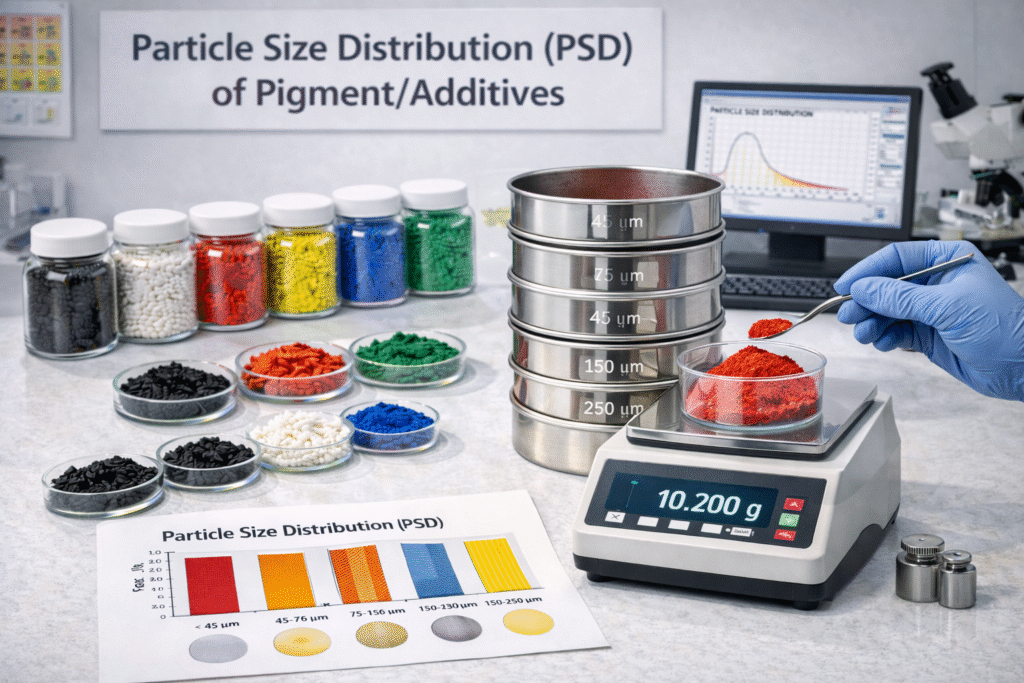

8. Particle Size Distribution (PSD) of Pigment/Additives

A key parameter affecting:

dispersion

opacity

gloss

filter life

What to Check:

D50, D90 particle size values

supplier pigment grade consistency

Why It Matters:

Larger particles cause:

streaks and non-uniform shade

reduced color strength

surface defects

poor UV resistance performance

In premium masterbatch manufacturing, pigment is micronized and stabilized for consistent PSD.

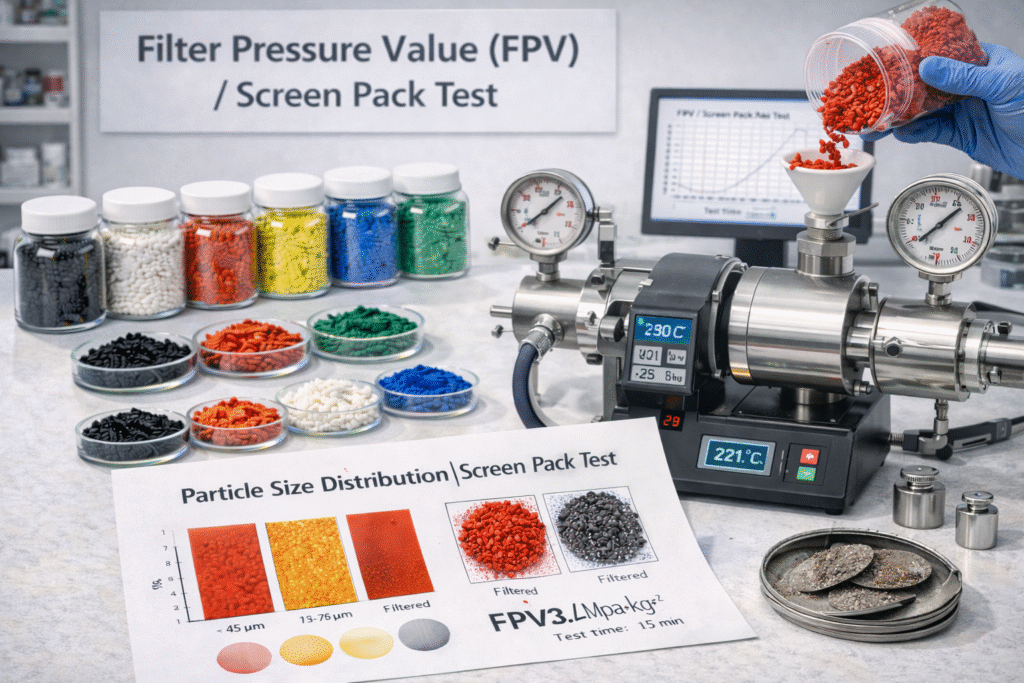

9. Filter Pressure Value (FPV) / Screen Pack Test

FPV indicates how clean the masterbatch is in terms of:

gels

carbon black lumps

unmelted particles

contamination

What to Check:

FPV test report

mesh size used (commonly 80/120/200 mesh)

Why It Matters:

High FPV means:

frequent screen change

downtime

high wastage

reduced extrusion output

For film extrusion companies, FPV is one of the most important procurement checks.

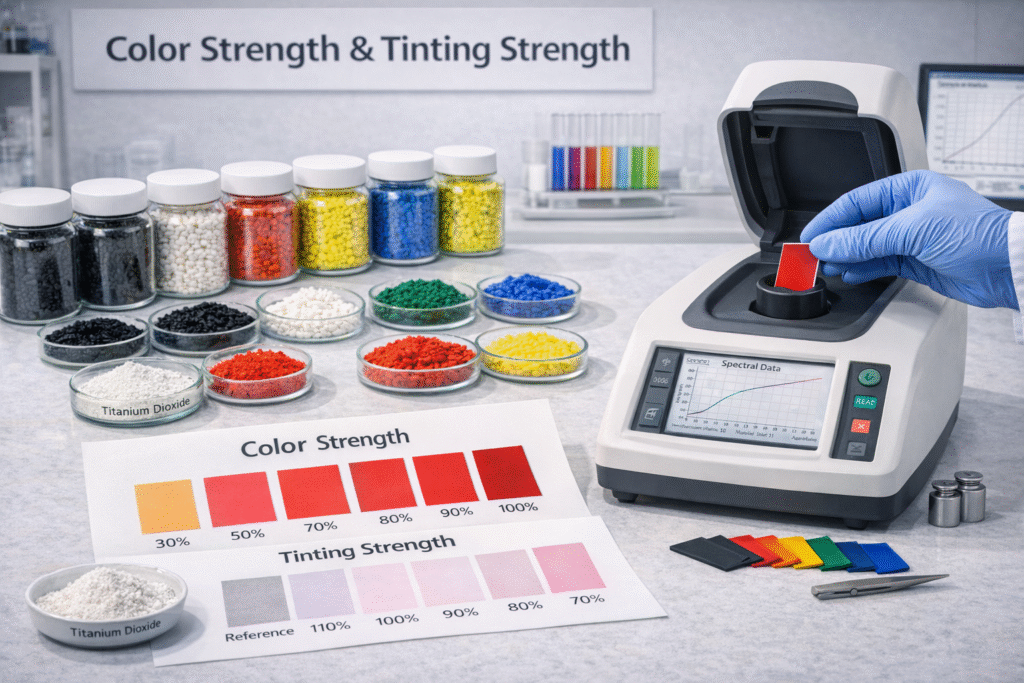

10. Color Strength & Tinting Strength

Color strength refers to how effectively the pigment colors the polymer.

What to Check:

ΔE value in lab testing

Tinting strength comparison

Spectrophotometer test report

Why It Matters:

If color strength varies:

dosing increases unexpectedly

shade mismatch in customer approval

higher consumption of masterbatch

Standard Testing:

Use spectrophotometer for:

Lab values*

ΔE measurement

reflectance curve matching

For B2B packaging and consumer goods, ΔE should ideally be:

≤ 1.0 for critical applications

≤ 1.5 for standard packaging

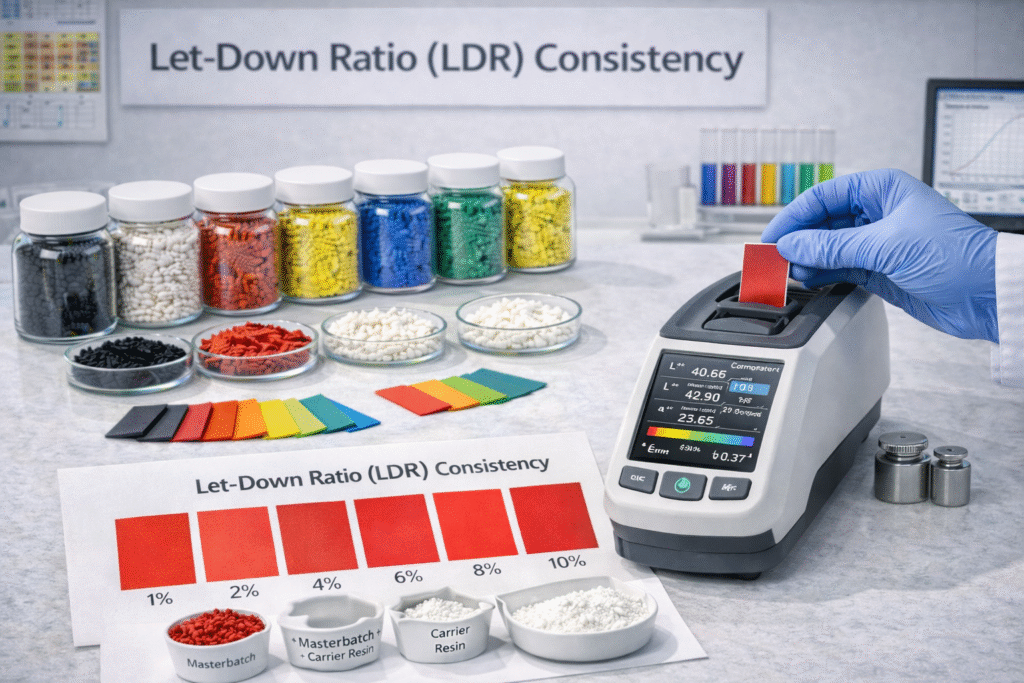

11. Let-Down Ratio (LDR) Consistency

Let-down ratio means how much polymer can be colored per kg of masterbatch.

What to Check:

Recommended dosing %

Real performance at customer site trials

Why It Matters:

Some suppliers claim:

LDR 1:50

But actual performance may be:

1:35

This directly increases raw material cost.

Procurement Tip:

Always conduct plant trial and validate:

actual shade match at given dosing

mechanical property retention

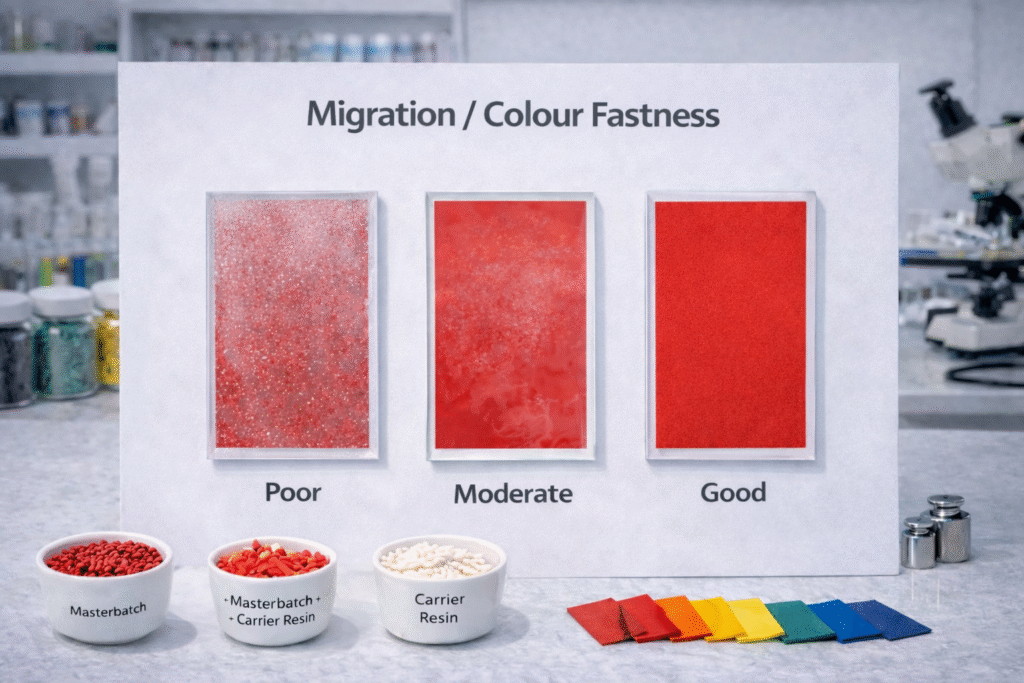

12. Migration / Colour Fastness

Migration occurs when additives/pigments move to the surface over time

What to Check:

Migration test report

surface blooming evaluation

compatibility with polymer

Why It Matters:

Migration causes:

surface whitening

oily layer formation

print adhesion failure

lamination issues

This is critical for:

packaging films

agricultural films

printed products

multilayer structures

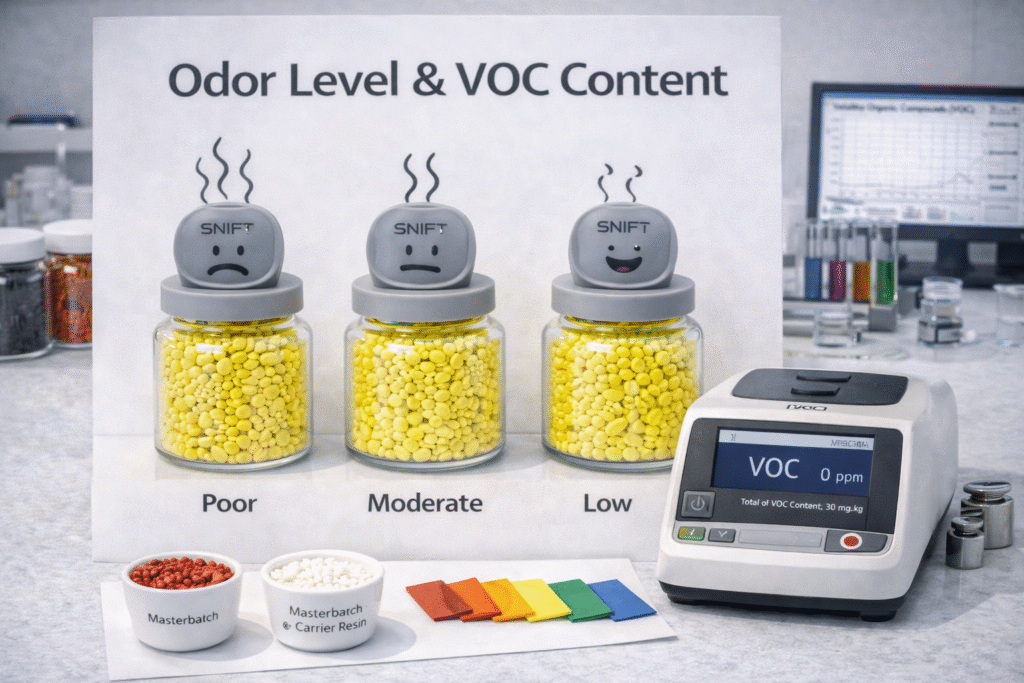

13. Odor Level & VOC Content

For packaging, medical, and consumer products, odor is critical.

What to Check:

Odor evaluation report

VOC compliance if applicable

Why It Matters:

Bad odor can lead to:

rejection from food packaging buyers

customer complaints

export shipment issues

Purchase managers must verify:

low odor pigments

food-grade compliant additives

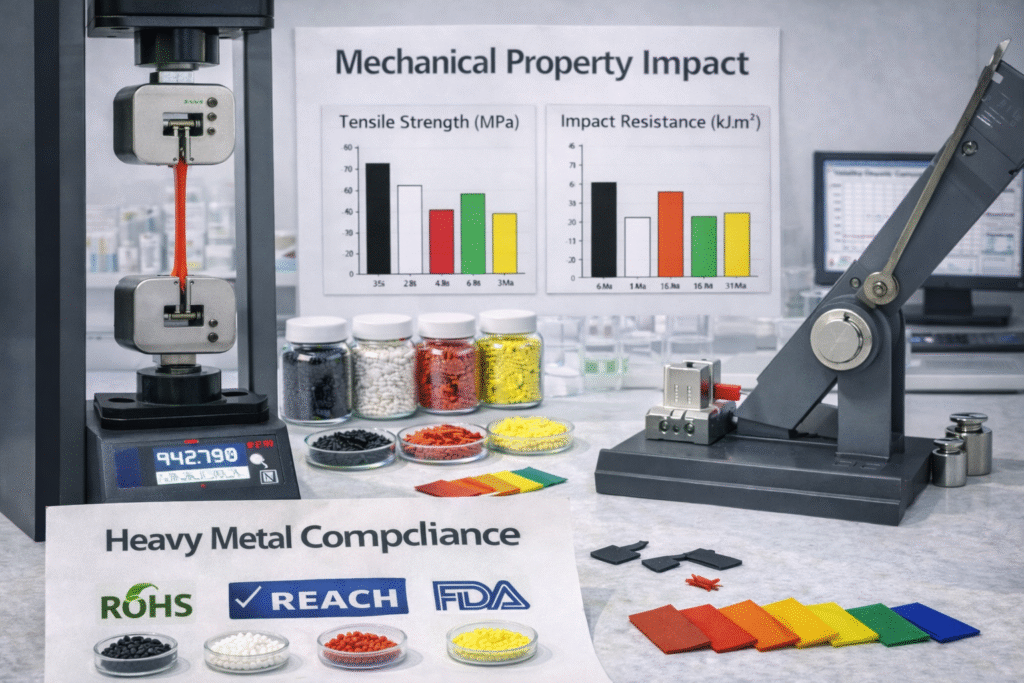

14. Heavy Metal Compliance (RoHS, REACH, FDA Requirements)

Many pigments contain traces of:

lead

cadmium

chromium

mercury

What to Check:

RoHS certificate

REACH compliance

FDA/food contact declaration (if required)

Why It Matters:

Non-compliance can lead to:

export rejection

legal penalties

loss of customer trust

Procurement should demand:

batch-wise compliance documentation

15. Mechanical Property Impact

Masterbatch must not degrade base polymer properties.

What to Check:

tensile strength retention

elongation retention

impact strength retention

Why It Matters:

Excess filler or poor carrier can reduce:

elongation in films

tear strength

ESCR (environmental stress crack resistance)

This becomes extremely important in:

stretch film

garbage bags

irrigation pipes

blow molded containers

Quality Parameters Checklist Purchase Managers Must Demand

Here is a professional checklist every procurement department should include in their vendor evaluation:

- COA (Certificate of Analysis)

- MFI report

- Dispersion rating report

- FPV/screen pack test report

- Ash content report

- Moisture content report

- Thermal stability test

- Spectrophotometer ΔE report

- Carrier resin declaration

- RoHS/REACH/FDA compliance certificates

- Batch consistency report (last 3 batches comparison)

Common Red Flags When Buying Masterbatch

If you see these warning signs, reconsider the supplier:

🚫 Supplier avoids giving COA

🚫 No batch-to-batch tracking

🚫 Shade differs in each lot

🚫 Excess dusting in granules

🚫 High contamination in packaging

🚫 Poor pellet cutting uniformity

🚫 High filter choking complaints

🚫 No lab testing setup

Best Procurement Practice: Standardize Your Masterbatch Evaluation

To reduce production risk, procurement teams should create:

Approved Masterbatch Specification Sheet

Including:

Carrier polymer

Melt flow range

Dispersion grade

Moisture max limit

Ash max limit

ΔE tolerance

letdown ratio

FPV max allowable

This ensures purchase decisions remain technical, not emotional or price-based.

Conclusion: Masterbatch Buying is a Technical Decision, Not a Commercial One

For B2B plastic processors, the cost of poor masterbatch quality is not limited to raw material—it affects:

machine performance

production output

downtime

scrap generation

customer complaints

brand reputation

A smart purchase manager evaluates masterbatch with technical parameters, documented test reports, and batch consistency assurance.

If your supplier cannot provide quality documentation, then the masterbatch is not a raw material—it becomes a production risk.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.