Injection Moulding

Applications

We Provide all types of injection moulded products solutions like cost, quality & properties etc. Bajaj also provides high efficiency and fast production, Injection Molding can handle extremely complex parts and uniformity. It helps to enhance the strength of the product, Flexibility of production is endless because of the wide range of material and color. It reduced waste and low labor costs. Bajaj Masterbatch provides customized products as per customer requirements.

NEED FOR

INJECTION MOULDING

Key Technical Features

High Quality and Sustainability

When looking for a high-volume injection molding process, it’s important to consider companies’ green manufacturing initiatives, as these signify a commitment to quality, sustainability, and optimal safety.

High Production Output

The process itself is extremely fast compared to other methods, and the high production output rate makes it even more efficient and cost-effective. Speed depends on the complexity and size of the mold but only about 15-120 seconds pass between each cycle time.

Lower Labour Cost

Labor costs are relatively low in plastic injection molding, in comparison with other types of molding. The ability to produce the parts at a very high level with a high output rate helps with its cost efficiency and effectiveness.

Strength

Strength is one of the key factors determined when designing a plastic injection molded part. The designer will ascertain if the part needs to be flexible or rigid based on it’s end application requirements .

Wide Variety

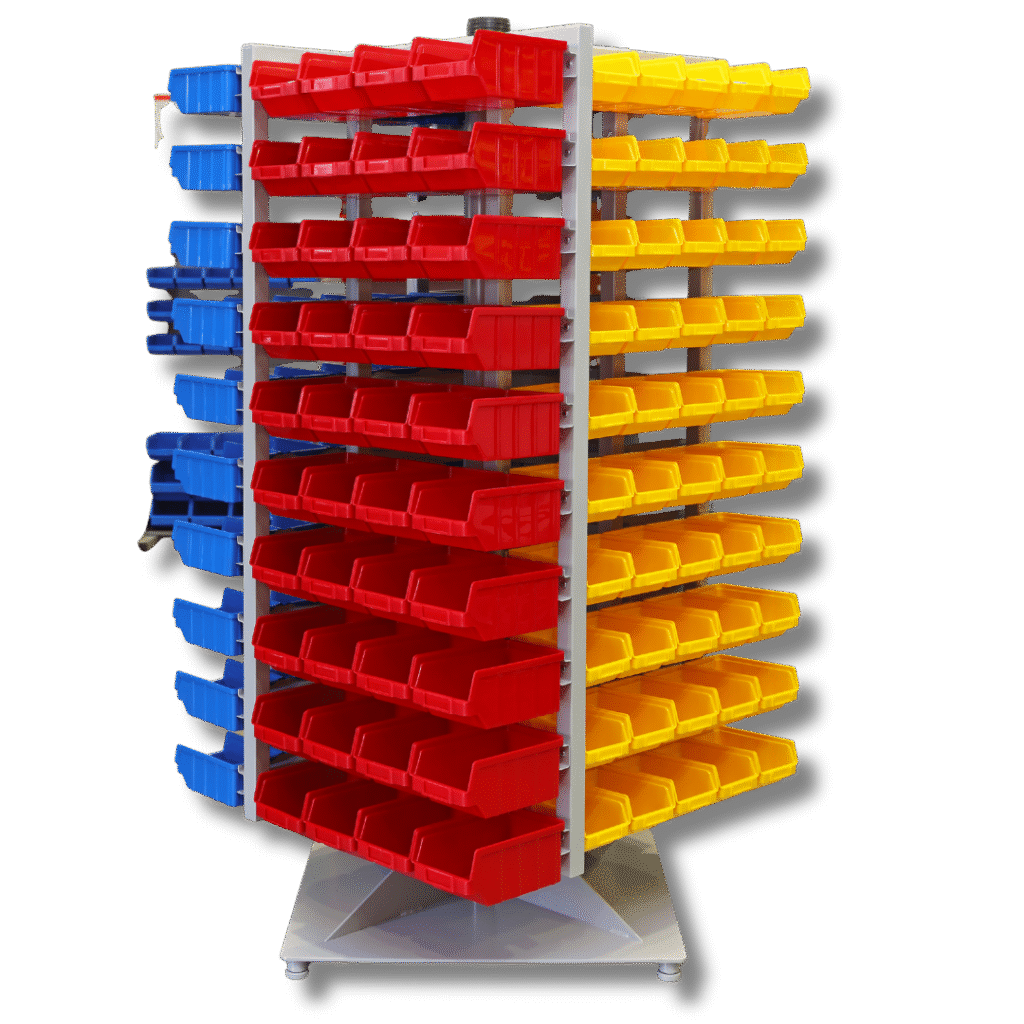

This is most common plastic processing technique used for manufacturing a wide variety of plastic items ranging from smallest components like Caps, buttons, Electrical & Electronic parts, buttons, etc to large components like Car bumper , dash board, Home Appliances body , etc.

TYPES OF

INJECTION MOULDING

Micro Injection moulding

is a process of obtaining micro injection moulded parts that weighs less than 1/10th of a gram, here very high precision is involved in both tooling as well as production.

Rapid Injection moulding

is a process to make prototype injection moulded parts in a thermoplastic resin in 2-5 weeks. These parts are used for full functional and fit testing.

Fusible core Injection moulding

is a specialized process used to manufacture components with cavities / undercuts .

2-Shot Injection Moulding

is a technology of producing a part with 2 different raw materials or colours in single operation.

Insert Moulding process

are mostly done in vertical injection machines with vertical / horizontal clamp unit. In this an insert is placed into the mould cavity before closing and the plastic is then injected around the insert so that the insert becomes a part of the final moulded product.

Injection compression Moulding

is a technique where the molten polymer is injected into a partially open mould , then the mould closes to compresses and distributes the melt through out the cavity , completing filling and packing stage. This process works on lower injection pressure providing lower moulded in stress and thin walled part production.

Foam Moulding Process

is a low pressure process inwhich an inert gas is introduced into molten polymer the purpose of reducing density and hence weight of the finished product. Moulded products have cellular cores surrounded by rigid, integral skins. Foaming agents such as Nitrogen, Carbon di oxide is introduced into the polymer melt stream, creating a homogenous mixture of polymer & gas.

Co-Injection(Sandwich) Moulding

is a process in which 2 different but compatible polymer melts are injected sequentially into a cold mould , forming a skin / core structure . The possibility of using recycled material in the core can be regarded as one of the key advantage in this process.

Gas assisted Injection molding

is used when any thick plastic injection-molded part is that it runs the risk of distortion as it cools. This method helps to solve this issue by shooting gas into a plastic material-filled injection mold, allows the plastic on the outside of the mold to maintain a smooth and finished appearance while the inside stays porous or hollow.

Thin wall moulding

It is a technology that achieves a plastic part with a very thin wall. It is often used in test apparatuses, electronic items, Food containers , tubes, and other enclosures.

Classification

Injections Moulding

Hand Moulding Machine

Vertical & Horizonatal type Injection Moulding Machine

Advantages of Using

Bajaj Injection Moulding Solutions

Complex Part Design

High Efficiency- Fast Production

Enhanced Strength

Flexibility- Material and Color

Reduced Waste

Low Labor Costs

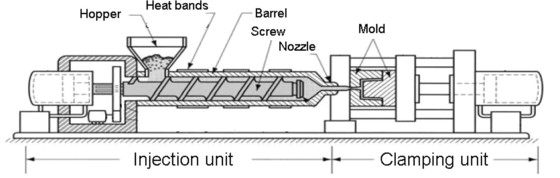

Clamping unit

They are placed at the back of the mould in the machine. Mould is clamped to platen of the machine. One platen is stationery which has injection unit at its back while the other one attached to clamping unit is movable. The main function of clamping unit is to keep mould closed when hot plastic material is injected into mould at high speed & pressures. In general, Clamping pressure has to be higher than the Injection pressure. There are 2 types of clamping units, namely

A) Direct Locking unit which utilize a high pressure hydraulic cylinder where clamping forces is focused in the centre providing even force distribution.

B) Toggle clamps which are mechanical clamping providing both high speed and high force at different points in the cycle when required.

Clamping force = Projected Area X Injection Pressure

The projected area of the part can be found based on the geometry ( dimensions) of the part. The injection pressure varies with the flow or viscosity of the polymeric material. Too low a clamping force can lead a short part or unfilled parts while too high clamping force can open mould leading to flash or even damage mould sometimes.

Bajaj Masterbatch

Injection Moulding Applications

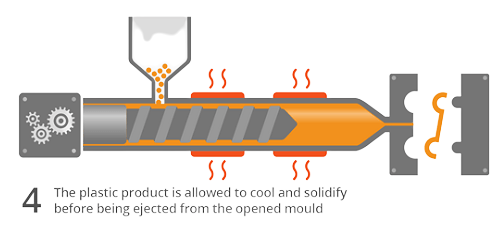

Injection Moulding

Process Cycle

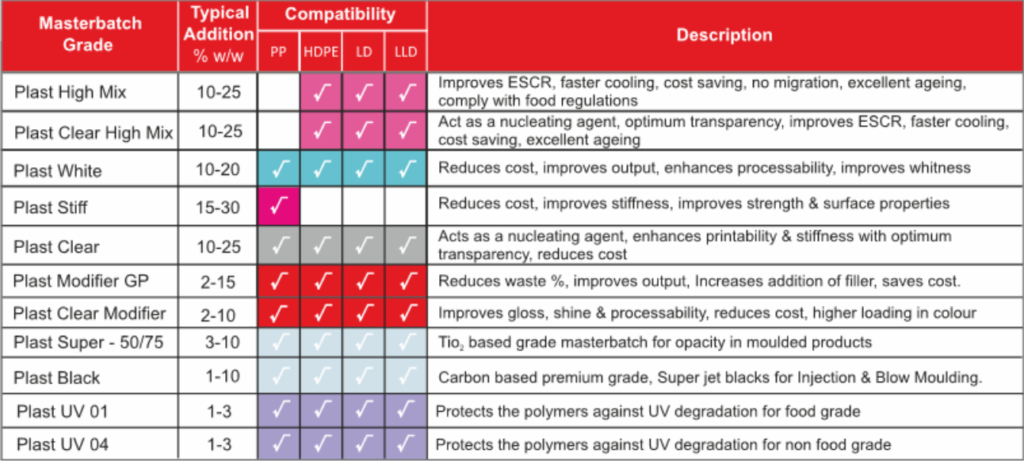

Product Solutions

for Injection Moulding

Filler Masterbatch For

Injection Moulding Applications

Fillers Reduce Cost and Weight by and large but most of the people

think these are simply used to add bulk and lower cost, but also these mineral fillers make them easier to mold and shape while ensuring the stability of the compounds used in the injection moulding process. Due to volatile pricing trends of polymer resins , processors has to expedite the usage of fillers as a solution to reduce cost without compromising the quality of outcome (ie) finished products.

White Masterbatch For

Injection Moulding Applications

Additive Masterbatch For

Injection Moulding Applications

Color Masterbatch For

Injection Moulding Applications

Injection Moulding

Product Types