as per your application

Know your masterbatch requirement

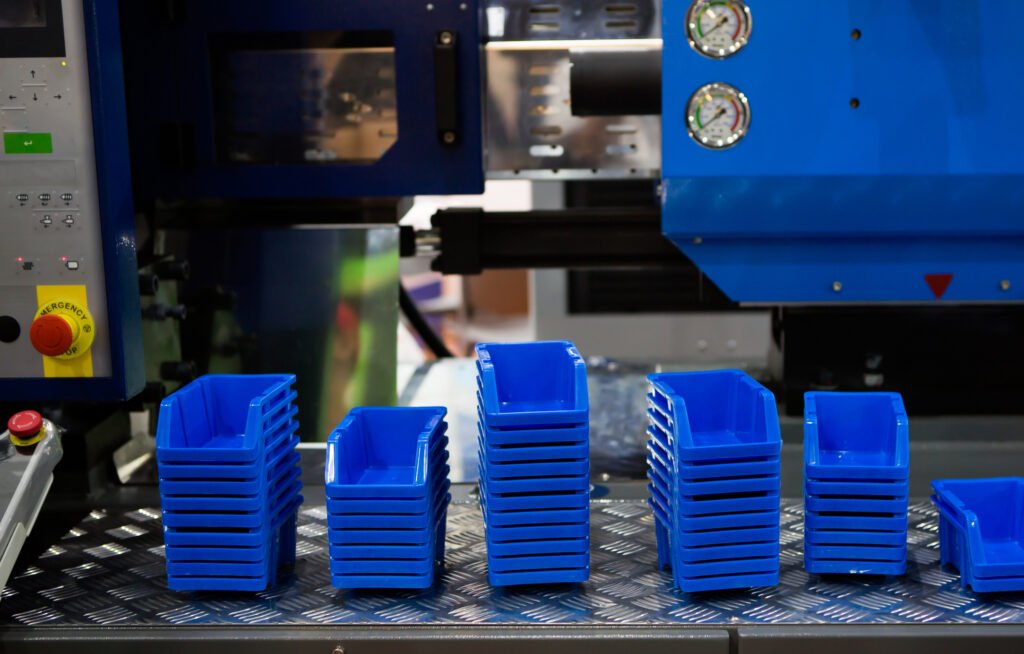

- Injection Moulding

- Blow Moulding

- Blow Moulded tanks

- Blown Film

- BOPP Films Extrusion

- Non Woven

- Thermoforming

- raffia / Woven Sack

- Geo Synthetics

- AD Star Bag

- FIBC Jumbo bag

- Leno Bags

- Tarpauline

- Geo Membrane

- Pipe Extrusion

- Foam Extrusion

- Box Strapping

- HDPE Monofilament Yarn

- Recycling Plastic

Plast Masterbatches for Injection Moulding Products

1. Plast Highmix – Improves ESCR, faster cooling, cost saving, no migration,excellent aging, food complaince.

2.Plast Clear Highmix – Act as a nucleating agent, optimum transparency, improves ESCR, faster cooling. cost saving, excellent ageing.

3.Plast White – Reduces cost, improves output, enhances processability, improves whitness.

4.Plast Stiff – Reduces cost, improves stiffness, improves strength & surface properties.

4. Plast Clear – Acts as a nucleating agent, enhances printability & stiffness with optimum transparency, reduces cost

4.Plast Modifier GP – Reduces waste %, improves output, Increases addition of filler, saves cost.

5.Plast Clear modifier – Improves gloss, shine & processability, reduces cost, higher loading in colour.

6.Plast Super 50/75 – Tio2 based grade masterbatch for opacity in moulded products

7.Plast Black – Carbon based premium grade, Super jet blacks for Injection & Blow Moulding

8.Plast UV 01 – Protects the polymers against UV degradation for food grade.

9.Plast UV 04 –Protects the polymers against! UV degradation for non food grade.

Plast Masterbatches For Blow Moulding products

1.PLAST SUPER 131,181 (70% TiO2 content)

2.PLAST SUPER 157, 132 (50% TiO2 content) – These products are having superior dispersion, opacity, gloss, ease of processing and food packaging compliant. Also, they do impart heat resistance & UV protection to the end product to certain extent

3.PLAST BLACK with Carbon content – 40% & 50% – made from high quality carbon black, filler free with excellent jetness & dispersion

4.PLAST FILL

5.PLAST CLEAR

6.PLAST HIGH MIX

fillers to increase output, economical advantage by reducing material cost and energy cost saving .

7.Plast color

8.Plast Additives

Plast Masterbatches For Blow Moulded Tanks

1.Plast HighMix – Improves ESCR, faster cooling, cost saving, no migration, excellent ageing, complies with food regulations .

2.Plast Clear HighMix – Acts as a nucleating agent, optimum transparency, improves ESCR, faster cooling. cost saving, excellent ageing.

3.Plast Modifier GP – Reduces waste %, improves output, Increases addition of filler, saves cost.

4.Plast Clear Modifier – Improves gloss, shine & processability, reduces cost, higher loading in colour.

5.Plast Black – Carbon based premium grade, Super jet blacks for Injection & Blow Moulding.

6.Plast Super 50/75 – TIO2 based Premium opacifying grade for film to comply with food regulations, reduces addition level of UV additives.

7.Plast UV01 – Protects the polymers against UV degradation for food grade.

8.Plast UV02 – Protects the polymers against UV degradation for non food grade.

Plast masterbatches For Blown Film Extrusion

1.Plast Fil – Out standing mechanical properties even at higher loading, improves opacity of film, food grade, applicable in multilayer films, Increases output, saves cost.

2.Plast HighMix PRM – Saves cost, increases output, good printability.

3.Plast Clear Film – With negligible reduction in transparency, economic grade for transparent film.

4.Plast Clear HighMix – With negligible reduction in transparency, saves cost

5.Plast Modifier GP – Out standing mechanical properties even at higher loading, improves opacity of film, food grade, applicable in multilayer films, Increases output, saves cost.

6.Plast Biodegradable – Degrades the polymer mix. Property of polymer such as strength flexibility sealability and easy processability is not effected.

7.Plast Black 35/60 – Carbon based premium grade, Super jet blacks for Monolayer film, Tarpaulin & moulding.

8.Plast UV01 – Protects the polymers against UV degradation for food grade.

9.Plast PPA – Ease of processability, increases output, eliminates the problem of melt fracture.

10. Plast VCI – Corrosion protection for various packaging industry

11.Plast Desiccant – Ease of processability, increases output, eliminates the problem of melt fracture protect from moisture degradation.

12. Optical Brightner- Eliminates Yellowness increases the brightness of the product

Plast Masterbatches For BOPP Films

1.PLAST SUPER 141 PP With 70% TiO2 content –

having superior dispersion, opacity, gloss, ease of processing and food packaging compliant. Also, they do impart heat resistance & UV protection to the end product to certain extent.

2.PLAST ANTIFOG

3.PLAST PPA

4.PLAST NUCLEATING

5.PLAST ANTISTAT

6.PLAST SLIP

7.PLAST ANTIBLOCK

Additive masterbatch to improve the overall performance of end product , they act as Modifiers, Property enhancers & Processing aids. Our Product profile includes.

8.PLAST COLOUR

produced with high pigment loading to provide light fastness, migration resistance, dispersion, thermal stability , food contact compliance & colour consistency for every supplied lot. We can offer wide range of Colours from our existing product range or customize based on pantone shades given by clients.

Masterbatches For Non Woven Fabric

1.PLAST SUPER 141 PP With 70% TiO2 content –

having superior dispersion, opacity, gloss, ease of processing and food packaging compliant. Also, they do impart heat resistance & UV protection to the end product to certain extent.

2.Additive Masterbatch

- Plast Anti Microbial

- Plast Anti Rodent

- Plast anti static

- Plast desccicant

- Plast PPA

- Plast Uv

- Plast Slip

- Plast Bright

3.PLAST COLOUR –produced with high pigment loading to provide light fastness, migration resistance, dispersion, thermal stability , food contact compliance & colour consistency for every supplied lot. We can offer wide range of Colours from our existing product range or customize based on pantone shades given by clients.

4.PLAST BLACK with Carbon content – 40% & 50%

made from high quality carbon black, filler free with excellent jetness & dispersion

5.PLAST FILL

6.Plast Highmix

Fillers to increase output, ability to down gauge, reduce material cost and energy cost saving

Masterbatches For Thermoforming

1.PLAST FILL – With finest particle size of CaCO3 facilitates reduction in Raw material cost with maximum loading, reduction in energy

consumption , cycle time gets reduced as it has good thermal conductivity & helps to reduce wall thickness.

2.PLAST SUPER WHITE – Having pure TiO2 content in it giving excellent opacity, brightness , whiteness with good light reflectance. Sutiable for any wall

thickness of items thermoformed.

3.PLAST COLOUR – Having high concentration of pigments , filler and contamination free yielding good color strength , aethetics, having good

light fastness, weathering resistance and adds shining to the finished products.

4.PLAST DESSICANT – Absorbs moisture to prevent surface defects ,gives mechanical strength & facilitates good mixing in the extruder.

5.PLAST BLACK – Having finest particle size carbon black pigments yielding good jetness, shining, smooth dispersion with ease in

process-ability.

Masterbatches For raffia / Woven Sack

1.Plast Stiff – Highly suitable for low denier tapes, improves stiffness, strength & surface properties, saves cost.

2.Plast Stiff PRM – Highly suitable for low denier tapes & high output extruder, improves strength & surface properties, reduces cost.

3.Plast White – Universal grade, saves cost, improves printability, output, enhances & processability

4.Plast White PRM – Specially for extrusion coating, for higher out put extruder, reduces cost, improves output, enhances processability, low waste %

5.Plast White HD -Reduces cost, improves strength & elongation, Improves output, low waste %

6.Plast Clear -Acts as a nucleating agent, enhances printing & stiffness with optimum transparency, saves cost.

7.Plast Super – 50/70 – Premium opacifying grade for film to comply with food regulations, reduces addition level of UV additives.

8.Plast Modifier –Improves elongation whiteness, gloss & processability, reduces cost

9.Plast Clear Modifier – Improves gloss, shine & processability, reduces cost, higher loading in colour.

10.Plast UV 01 – Protects the polymers against UV degradation for food grade application

11.Plast UV 04 – Protects the polymers against UV degradation for non food grade application

12.Plast Antistatic – The product protect FIBC/Jumbo Bag from static charge

Masterbatches For Geo Synthetic Applications

1.PLAST BLACK – With good jetness, weathering (ESCR), compatibility with any kind of applications -Land fill liners & caps, Tunnel lining , Pond liners & waste water lagoons.

2.PLAST UV – With high molecular weight HALS chemistry to retain the polymer properties for long term durability.

3.PLAST ANTIOXIDANT – Gives good heat stability, chemical resistance , Weathering (ESCR) , etc.

Masterbatches For AD Star Bags

1.Plast Stiff improves strength, stiffness, modify physical & mechanical properties and reduces your processing and product cost. It is used only for PP based.

2.Plast Clear acts as nucleating agent and it enhances printing & stiffness. It is mainly used for transparent application. It reduces your processing and product cost.

3. Plast Modifier improves whiteness and gloss and increases processability.

4.Plast White a universal grade. It improves printability and out. It is also useful for enhancing processability and saving the process & production cost.

5. Additive Masterbatch –

7.TIO2/White Masterbatch

- Plast super – 40%

- Plast super – 50%

- Plast super – 70%

- Plast super – 75%

Masterbatches For FIBC Jumbo Bags

1.White/TIO2 Masterbatch –

1.Plast Super 134 50%

2.Plast Super 70-151 50%

3.plas Super 131 50%

2.UV Masterbatch

- Plast UV 04 PP PRM

- Plast UV 04 PP AB

- Plast UV 04 PP MF

- Plast UV 04 PP FIBC

- Plast UV 04 PE AB

- Plast UV 04 PE MF

- Plast UV 01 PP Food garde

- Plast UV 01 PE Food Grade

3.Additive Masterbatch-

1.Anti block masterbatches facilitates co-efficient of friction & prevents sticking of PE films used as liners in FIBC ,

2.Antistatic masterbatches neutralizes the build up of static electric charges enabling FIBC bags to prevent occurrence of flammable sparks while carrying inflammable items

Masterbatches for Leno Bags

1.Plast Color Masterbatches

2. Plast UV Masterbatches

1.Plast UV PP MF

2. Plast UV PE MF

3.Plast UV PE Food Grade

Masterbatches For Tarpauline

1.Plast Color Masterbatches

2. Plast UV Masterbatches

1.Plast UV PP MF

2. Plast UV PE MF

3.Plast UV PE Food Grade

Masterbatches For Geo Membrane

Masterbatches For Geo Synthetic Applications

1.PLAST BLACK – With good jetness, weathering (ESCR), compatibility with any kind of applications -Land fill liners & caps, Tunnel lining , Pond liners & waste water lagoons.

2.PLAST UV – With high molecular weight HALS chemistry to retain the polymer properties for long term durability.

3.PLAST ANTIOXIDANT – Gives good heat stability, chemical resistance , Weathering (ESCR) , etc.

4.Plast Antistatic

5.Speciality White Masterbatch

6.Plast UV PP/PE 04 Masterbatch

Masterbatches For Pipe Extrusion

1.HDPE Pipes

PLAST BLACK – With fine parcle size of carbon, jetness, dispersion, gloss & free from fillers.

PLAST PPA- Helps to Improve product surface quality, increase surface gloss, reduce the melt pressure, increase product quality & production efficiency.

PLAST COLOUR – With good pigment loading , no migration , excellent light fastness and can be loaded with low dosage levels to get good colour strength. reduce the melt pressure, increase product quality & production efficiency.

PLAST MODIFIER – Which facilitates mechanical strength , increases Tensile strength, Elongation & output .

2.PP-R Pipes

PLAST COLOUR GREEN – With good pigment loading , no migration , excellent light fastness, heat stable, weather resistant, food grade compliant.

PLAST PPA – Helps to Improve product surface quality, increase gloss, smooth surface , reduce the melt pressure during processing & enhances productivity.

PLAST UV- With food grade compliance , facilitates outdoor UV rays stabilization and protects.

PLAST ANTIOXIDANT-To facilitate thermal stability in hot water applications.

PLAST NUCLEATING AGENT – To get crystallinity, clarity in surface and facilitates productivity enhancement.

3.Corrugated Pipes

PLAST COLOUR (GREEN,BROWN,GREY,BLUE,etc) & PLAST SUPER WHITE – With high pigment loading , no migration , excellent light fastness, heat stable, weather resistant, foodgrade compliant.

PLAST PPA – Helps to Improve product surface quality, increase gloss, smooth surface , reduce the melt pressureduring processing & enhances productivity.

PLAST UV – With food grade compliance , facilitates outdoor UV rays stabilization and protects the substrate of pipes.

Masterbatches For Foam Extrusion

PLAST CLEAR FILLER – Talc based transparent filler to facilitate smooth processing by means of creating cell structure , reducing cost by

replacing polymer content , power consumption and enhanced productivity.

PLAST ANTISTATIC ADDITIVE – Masterbatch acts as a surface active agents, prevents moisture entrapment in cell structure, uniform size distribution in cell structure and minimizes the build up of static electricity on finished foam sheets.

PLAST COLOUR MASTERBATCHES – In various shades as per the requirements to give aesthetic appeal, heat & weather resistant .

PLAST BLACK – With finest carbon particles gets uniformly distributed in foam structure to give good jetness, smooth surface finish and UV resistance to certain extent when exposed in outdoor applications.

Masterbatches For Box Strapping

PLAST STIFF – CaCO3 based mineral filler to optimize the cost by substituting virgin polymer without compromising on mechanical

properties such as Tensile & elongation. Also it facilitates energy savings, smooth dispersion and improves productivity as well.

PLAST MODIFIER – CaCO3 & Elastomer based compound to enhance the mechanical strength to the strap & act as an excellent bonding

agent as well. It improves whitenss , smooth dispersion, gloss & shining to the end product.

PLAST SUPER WHITE – Made with Pure TiO2 having no filler, contaminants could be easily dispersed, gives whiteness, opacity , brightness to the strap.

PLAST COLOUR – With wide range of shades with good quality pigments, filler free, having good heat & weathering resistance and add aesthetics to the strap.

PLAST BLACK – With finest Carbon black particle size , free from filler could be well dispersed during processing and gives good jetness,

shining and gloss to the strap.

Masterbatches For HDPE Monofilament Yarn

PLAST Fab – Plast PP FAB 780 & 783 are use in PP/PE slings applications, Yarns, Ropes, Tapes, Mosquito Nets ,Leno Bags.

PLAST Color – Color Masterbatch PP/PE slings applications, Yarns, Ropes, Tapes, Mosquito Nets ,Leno Bagsdes with good quality pigments, filler free, having good heat & weathering resistance and add aesthetics to the strap.

Masterbatches For Recycling Plastic

1.Antioxidant Additive masterbatch

2.Desiccant Additive Masterbatch

3.Polymer Processing Aid Additive Masterbatch

4.Odour remover Additive Masterbatch