Blow Moulding

Applications

Blow Moulding process is simple & effective way of producing complex, intricate hollow shapes that are light weight and have excellent stiffness to weight ratios.

Blow molding is a cost-effective alternative to injection molding, with both production and machinery being cheaper typically.

Blow molding works well for products that are one single piece in mass volumes.

The costs in blow molding are lower as compared to injection molding because machinery costs are typically lower as well. In blow moulding process, one-piece construction is done so that there’s no need to connect part halves, which can achieve shapes that injection molding cannot produce

NEED FOR

BLOW MOULDING

Blow molding is a cost-effective alternative to injection molding, with both production and machinery being cheaper typically. Blow molding works well for products that are one single piece in mass volumes.

In blow moulding process, one-piece construction is done so that there’s no need to connect part halves, which can achieve shapes that injection molding cannot produce.

Blow Moulding process is simple & effective way of producing complex, intricate hollow shapes that are light weight and have excellent stiffness to weight ratios. Various types of Bottles, Jerry cans, Containers, Drums, Carboys & Water tanks are also made through this process.

Blow Moulding process is simple & effective way of producing complex, intricate hollow shapes that are light weight and have excellent stiffness to weight ratios. Various types of Bottles, Jerry cans, Containers, Drums, Carboys & Water tanks are also made through this process.

TYPES OF

BLOW MOULDING

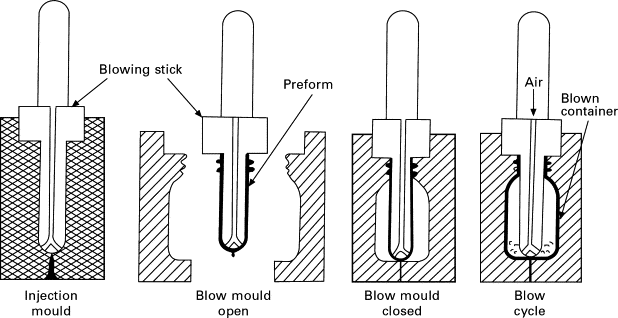

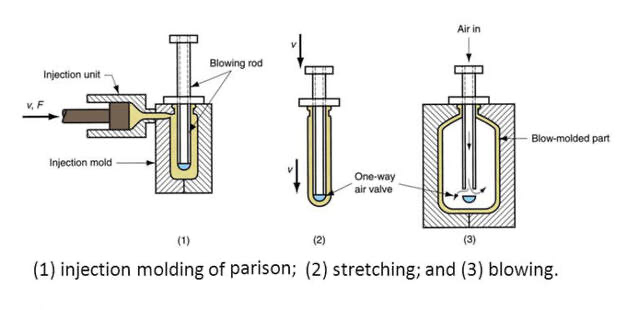

A) Extrusion blow molding(one stage)

B) Injection blow molding (one stage)

C) Injection stretch blow molding (two stages)

Advantages of Using

Bajaj Masterbatch for Blow Moulding

Ability to handle complex part

Fast Production Rate

Enhanced Strength

Increases the tensile strength

High level of producivity

Low Costs

Instead of having pre coloured compounds, usage of our masterbatches facilitates low stock holding as and when required.

Compared to compounds, our masterbatches gives a choice of wide range of colors and other properties besides saving huge cost as the inventory level & space required is very minimal .

Provides “dust free” environment without any health or safety risks in comparision to conventional usage of pigments powders & additives individually.

Optimum dispersion of pigments and additives in our masterbatches facilitates ease of processing. Also, it reduces the cost of purging & flushing .

Elimination of ‘trial and error’ development or formulation work, as this is done already by us ensuring color strength and consistency forever.

Our masterbatches are filler free and they are fairly highly concentrated (in comparison with the target composition), with “let-down ratios” affordable and economical as per the client’s application requirements.

Provides aesthetic appeal with gloss and brightness on the finished product without any surface defects.

As blow moulded bottles, containers, carboys and drums are extensively used in Pharma and Chemical applications, our masterbatches has the ability to maintain the chemical stability of the pigments and other ingredients incorporated in it. This facilitates migration resistant , leaching free and non reactive & ease of using at any conditions.

We use eco friendly pigments which are not harmful to the environment, on request we can provide ROHS (Restriction of Hazardous Substance) compliance.

Ease of consolidation with polymer at any addition levels and has uniform dispersion.

They are suitable for food contact applications as the ingredients used in it are non-toxic , non hazardous and the articles incorporated with our masterbatches are safe for use.

Product Solutions

for Blow Moulding

Blow Moulding Applications For

Color Masterbatch

Blow Moulding Applications for

White Masterbatches

PLAST SUPER 131,181 (70% TiO2 content), PLAST SUPER 157, 132 (50% TiO2 content). These products are having superior dispersion, opacity, gloss, ease of processing and food packaging compliant. Also, they do impart heat resistance & UV protection to the end product to certain extent.

Blow Moulding Applications For

Black Masterbatch

Blow Moulding Applications for

Talc Masterbatch