AntiStat Additive

Masterbatch

Static Charges attracts surface dust on plastics

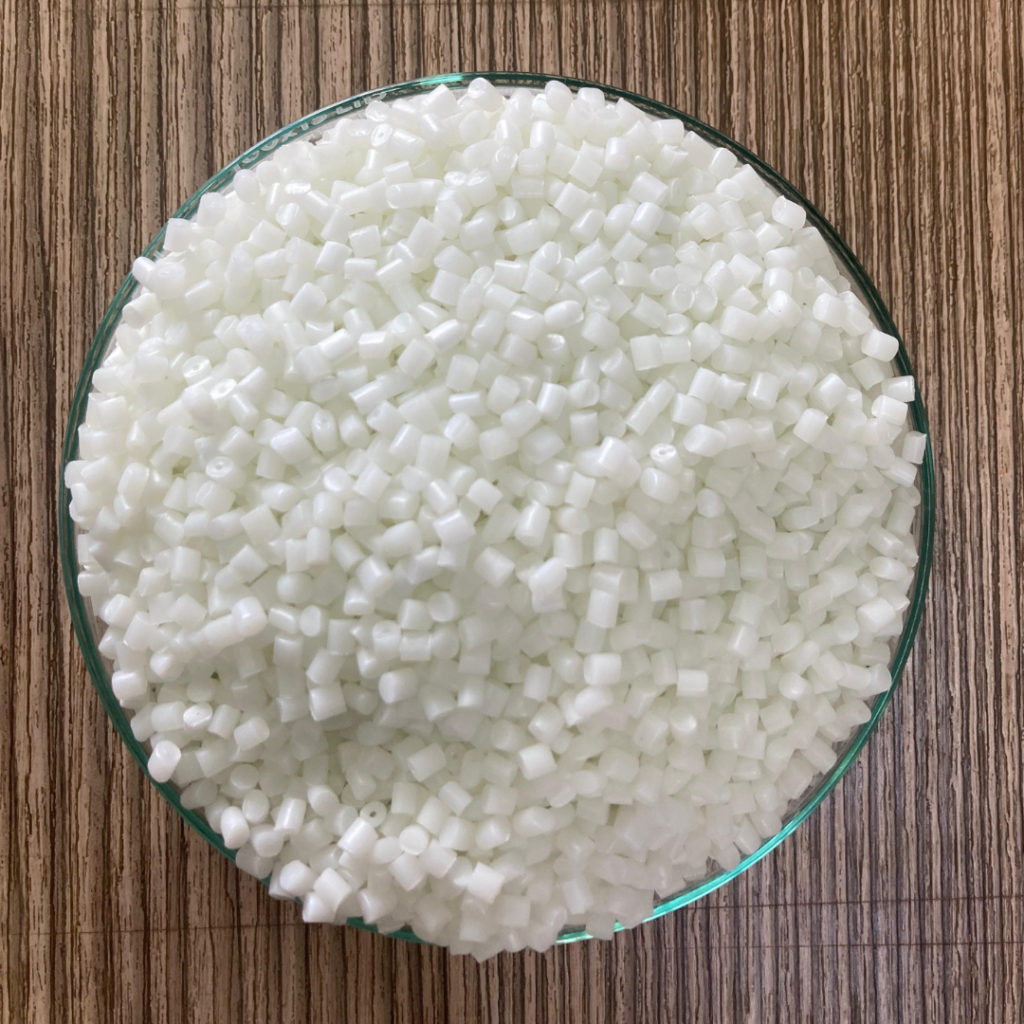

Antistatic additive masterbatch is engineered to minimize or eliminate the buildup of static electricity on plastic surfaces. In applications where static charge can lead to dust attraction, handling issues, or even the risk of electrostatic discharge (ESD), antistatic masterbatch offers a reliable, cost-effective solution.

How It Works

This masterbatch contains specially selected antistatic agents that migrate to the surface of the polymer matrix and attract moisture from the air. This layer of moisture forms a conductive path that allows static charges to dissipate gradually rather than accumulating. The formulation is tailored for compatibility with a wide range of polymers such as LDPE, LLDPE, HDPE, PP

Versatile formulations

Long-lasting anti-static properties

Cost-effective solution

Antistatic additive masterbatch is a high-performance solution designed to reduce or eliminate static electricity on the surface of plastic products. Whether you’re manufacturing packaging for electronics or producing components for cleanroom environments, our antistatic masterbatch ensures safer, cleaner, and more reliable end-products.

Reduce Static. Improve Safety.

Antistatic additive masterbatch is a specialized concentrate formulated with ionic or non-ionic antistatic agents dispersed in a compatible carrier resin. It is designed to reduce the surface resistivity of thermoplastics, enabling controlled dissipation of electrostatic charges through the surface layer of the polymer matrix. The mechanism involves hygroscopic additives that attract ambient moisture, thereby forming a thin conductive layer that facilitates charge leakage.

Engineered to Neutralize Surface Charge in Polymeric Systems

Mechanism of Action

Static charges are typically generated during high-speed processing operations (e.g., film winding, extrusion, injection molding) or friction during handling. Without proper dissipation, charges accumulate and may lead to:

Electrostatic discharge (ESD) events

Dust attraction and contamination

Safety hazards in flammable environments

Product handling and stacking issues

The antistatic agents in our masterbatch function via:

Surface migration and formation of a semi-conductive layer (migratory types)

Surface migration and formation of a semi-conductive layer (migratory types)

Moisture uptake, enabling ionic charge conduction in the presence of atmospheric humidit

Reduces static cling and dust attraction

Prevents ESD-related damage in electronic applications

Improves safety in flammable environments

Enhances packaging cleanliness and product aesthetics

Plastic materials naturally accumulate static charges, which can attract dust, cause handling issues, or even lead to electrostatic discharge (ESD) – especially dangerous in sensitive or flammable environments. Our antistatic additive masterbatch works by improving surface conductivity, allowing the static charges to safely dissipate.

Processing Compatibility

Compatible with injection molding, extrusion, blow molding, and film blowing processes

Dosage typically ranges from 1% to 5% depending on polymer type and desired resistivity

Thermal stability up to 300°C, ensuring no degradation during standard polymer processing

Our antistatic masterbatch can be customized based on:

Required surface resistivity (in ohm/sq)

End-use environmental conditions (humidity, temperature)

Compliance and regulatory needs

Plast antistatic masterbatch is helping plastic manufacturers from numerous industries produce static electricity-free products. Want more information? Need a consultation? Get in touch today. We will be happy to provide assistance.

AntiStat Additive

Surface Conductivity for Safer Plastics

Permanent or Migratory Systems

Available in both migratory (external) and permanent (internal) antistatic systems depending on application and life-cycle needs.

Excellent Dispersion

Uniform dispersion of the additive ensures consistent surface resistivity.

No Impact on Mechanical Properties

Maintains base polymer’s tensile strength, elongation, and clarity.

Food-Grade Options Available

Suitable for food contact applications as per FDA/EU regulations.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.