Benefits of PPA masterbatch in industrial applications

In industrial applications, efficiency, productivity, and product quality are paramount. That’s where the PPA masterbatch comes into play. PPA masterbatch, or polymer processing aids masterbatch, offers an array of benefits that contribute to optimized manufacturing processes and superior end products. Let’s delve into the advantages that make PPA masterbatch a game-changer in industrial applications.

PPA masterbatch (processing aids masterbatch) is a specialized additive formulation used in polymer processing applications

1. Understanding PPA masterbatch

1.1. The definition of PPA masterbatch

PPA masterbatch, also known as polymer processing aids masterbatch, is a specialized additive formulation used in polymer processing applications. It is typically composed of a carrier resin, such as polyethylene or polypropylene, blended with a small concentration of active ingredients known as polymer processing aids (PPAs). These PPAs are typically high molecular weight compounds, such as acrylic copolymers or fluoropolymers, that possess unique properties to enhance the processing characteristics of polymers.

1.2. The purpose of PPA masterbatch

The primary purpose of PPA masterbatch is to improve the processing efficiency and performance of polymers during various manufacturing processes. When added to polymer formulations, PPA masterbatch acts as a lubricant and flow enhancer, reducing the friction between polymer molecules. This helps to overcome processing challenges and optimize the flow behavior of the melted polymer.

1.3. How PPA masterbatch improves the processing characteristics of polymers

1.3.1 Melt flow improvements

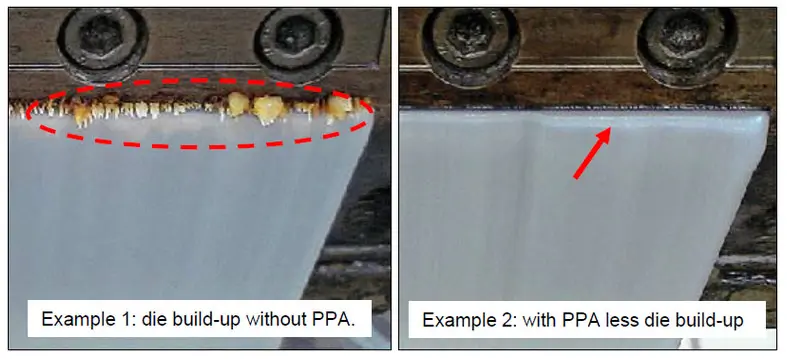

PPA masterbatch reduces the viscosity and melt strength of polymers, allowing for smoother and more uniform flow during processing. It helps to overcome processing difficulties such as melt fracture, die build-up, and sticking. By reducing the resistance to flow, PPA masterbatch enables better control over the polymer melt, leading to improved productivity and enhanced processing efficiency.

1.3.2. Enhanced mold filling

The addition of PPA masterbatch improves the flowability of melted polymers, allowing them to fill the mold cavities more effectively. This leads to better replication of intricate details and reduced occurrence of surface defects, resulting in improved part quality and dimensional accuracy. The enhanced mold filling also helps reduce the processing pressure, enabling the use of lower processing temperatures and reducing the risk of thermal degradation.

1.3.3. Reduction of processing temperature

PPA masterbatch reduces the melt viscosity of polymers, enabling them to flow more easily at lower processing temperatures. This temperature reduction can result in energy savings during processing and minimize the risk of thermal degradation, particularly for heat-sensitive polymers. By optimizing the processing temperature, PPA masterbatch helps maintain the integrity of the polymer and improves the overall efficiency of the manufacturing process.

1.3.4. Homogeneity and consistency

PPA masterbatch promotes better dispersion and distribution of additives, fillers, and pigments throughout the polymer matrix. This ensures a more homogeneous and consistent blend, leading to improved product quality and performance. The enhanced dispersion also helps prevent agglomeration and reduces the risk of uneven properties within the final product.

Enhancing polymer performance and processing efficiency across a range of manufacturing processes is the main goal of PPA masterbatch

2. Benefits of PPA masterbatch in industrial application

2.1. Enhanced processability

PPA masterbatch significantly improves the processability of polymers during manufacturing. It reduces viscosity and enhances melt flow properties, making the materials easier to process. This leads to smoother processing operations, reduced processing difficulties, and improved overall productivity. Manufacturers can achieve higher production rates and faster cycle times, resulting in increased efficiency and cost-effectiveness.

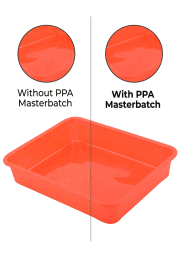

2.2. Improved surface finish

The use of PPA masterbatch in industrial applications helps achieve superior surface finish in the final products. It minimizes surface defects, such as flow marks, weld lines, and sink marks, resulting in a smoother and more aesthetically pleasing appearance. This benefit is particularly crucial in industries like automotive, consumer goods, and electronics, where visual appeal is essential.

2.3. Reduced processing issues

PPA masterbatch acts as a lubricant and reduces the friction between polymer molecules during processing. This property helps prevent issues like melt fracture, die build-up, and sticking, which can hamper productivity and degrade product quality. By mitigating these processing issues, PPA masterbatch ensures smoother operations, reduces downtime for maintenance, and improves overall production efficiency.

2.4. Enhanced mechanical properties

PPA masterbatch improves the mechanical properties of polymers, making them stronger, tougher, and more durable. It enhances dimensional stability, impact resistance, and tensile strength of the materials. This benefit is particularly valuable in applications where robustness and reliability are crucial, such as in automotive components, construction materials, and industrial equipment.

2.5. Cost savings

The use of PPA masterbatch can lead to significant cost savings in industrial applications. By enhancing processability and reducing processing difficulties, manufacturers can minimize material waste and scrap rates. The improved melt flow properties and reduced energy consumption contribute to cost-efficiency and sustainability. Additionally, the enhanced mechanical properties of the final products can extend their lifespan, reducing the need for frequent replacements and maintenance.

2.6. Compatibility with various polymers

PPA masterbatch exhibits excellent compatibility with a wide range of polymers, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and more. This versatility allows manufacturers to incorporate PPA masterbatch into different polymer formulations without compromising performance. It ensures consistent results across various materials and applications.

2.7. Facilitates complex processing techniques

PPA masterbatch enables the successful implementation of complex processing techniques, such as blow molding, injection molding, extrusion, and film casting. It improves melt stability, reduces viscosity variations, and enhances flow control during these intricate manufacturing processes. This benefit opens up possibilities for innovative product designs and advanced manufacturing techniques.

2.8. Customizable solutions

PPA masterbatch formulations can be customized to address specific processing challenges or to meet unique requirements of different industrial applications. Manufacturers can work closely with suppliers to tailor PPA masterbatch solutions that optimize processability, enhance product quality, and address specific industry regulations or standards. This customization ensures a more precise and effective solution for each application.

2.9. Regulatory compliance

PPA masterbatch formulations can be developed to comply with industry regulations and standards, such as FDA (Food and Drug Administration) regulations for food contact applications or specific safety requirements. This ensures that the final products meet the necessary compliance criteria, allowing manufacturers to confidently use PPA masterbatch in applications with strict regulatory guidelines.

PPA masterbatch is used in industrial applications to help produce final products with superior surface finishes

3.Technical Overview

Plast PPA are advanced fluoropolymer-based extrusion process aid masterbatches engineered to overcome processing limitations in polyolefin extrusion. Designed specifically for blown film, cast film, pipe, wire & cable, fiber, and blow molding operations, these process aids ensure stable production, superior surface quality, and extended operational efficiency.

By incorporating <0.1% addition level into resin formulations, Plast PPA effectively eliminates melt fracture, reduces die pressure, minimizes torque/amperage, and prevents die lip buildup—delivering both quality consistency and economic benefits across extrusion processes.

PPA masterbatch (processing aids masterbatch) is a specialized additive formulation used in polymer processing applications

4.Technical Application Benefits

Blown Film Extrusion

- Eliminates sharkskin and melt fracture at high shear rates

- Reduces die pressure, lowering motor load and energy consumption

- Allows higher output rates without compromising film quality

- Improves gauge uniformity and clarity

Pipe Extrusion (HDPE / PPR / LLDPE pipes)

- Minimizes die buildup and associated downtime

- Reduces sagging in large-diameter pipes

- Enhances surface gloss and dimensional stability

- Supports higher production rates without melt fracture

Wire & Cable Insulation (PE/PP)

- Prevents melt fracture at high line speeds

- Provides smooth insulation surfaces for consistent dielectric strength

- Reduces scrap caused by surface defects and line stoppages

Blow Molding (Containers & Drums)

- Reduces flow marks and weld-line visibility

- Enhances wall thickness distribution

- Improves cycle time by reducing melt flow resistance

Cast Film (CPP, LLDPE)

- Excellent thermal stability compared to PEG-based process aids

- Reduces die-lip deposits and downtime for cleaning

- Supports continuous operation for high-clarity packaging films

Fiber Spinning (PP/PE Fibers, Nonwovens)

- Improves surface smoothness and fiber aesthetics

- Minimizes fiber breakage at high draw ratios

- Reduces downtime caused by spinneret fouling

5.General Processing Advantages

- Smooth throughput across all extrusion lines

- Reduced extrusion pressure and lower amperage → improved energy efficiency

- Extended die cleaning cycles → fewer interruptions, lower maintenance cost

- Reduced start-up conditioning time → faster grade/product transitions

- Compatibility with pigments & fillers → effective even in high TiO₂ or CaCO₃ masterbatches

- Thermally stable formulation → no degradation under high processing temperatures

- Regulatory compliance → suitable for food contact and potable water applications*

6.Technical Superiority vs. Conventional Process Aids

- Low dosage efficiency: <1000 ppm required, unlike conventional PEG-based aids which demand higher levels (1–2%)

- No gel formation or degradation under thermal stress

- Non-interactive with HALS, anti-block, slip agents, and fillers

- Improved line economics: lower additive loading + reduced downtime + higher output → measurable cost savings

7.Typical Application Guidelines

- Dosage: 200–1000 ppm for direct use in LLDPE, LDPE, PP resins; 2–4% in masterbatch form

- Suitable Processing Conditions: Extrusion lines running with MI ≥ 3 LLDPE, LL/LD blends, or PP resins

- Processing Impact: Up to 20% increase in throughput in blown film extrusion

- 30–50% longer die-cleaning intervals in pipe and film extrusion

- Reduced melt temperature by 5–10°C, lowering energy costs

8.Product Grades

Both grades offer identical benefits; they differ in the rheological profile of the fluoroelastomer component, allowing processors to select the optimum grade for their resin systems and line conditions.

9.Summary for Technical & Purchase Teams

- Higher line speeds without melt fracture

- Improved surface finish and mechanical properties

- Lower overall operating costs due to reduced downtime and lower additive usage

- Regulatory compliance for food-contact and potable water applications

10. PPA masterbatch at Bajaj Plast

With nearly 35 years of experience, Bajaj Plast has emerged as a renowned manufacturer of filler masterbatch, establishing a distinguished reputation within the industry. Bajaj Plast offers PPA masterbatch to cater to diverse application requirements and enhance the quality of your end products.

To learn more about Bajaj Plast’ PPA masterbatch, kindly visit the PPA masterbatch Search

11. Conclusion

PPA masterbatch has emerged as a transformative force in industrial applications, fundamentally reshaping manufacturing processes with its wide-ranging benefits. By enhancing efficiency, elevating product quality, and driving cost savings, PPA masterbatch offers an unparalleled advantage to industrial businesses.

Its ability to improve processability, deliver impeccable surface finishes, enhance mechanical properties, exhibit compatibility with diverse polymers, and enable advanced processing techniques empowers manufacturers to reach unprecedented levels of productivity and innovation. With the integration of PPA masterbatch into their operations, industrial businesses can optimize performance, craft superior products, and maintain a competitive edge amidst the ever-evolving landscape of today’s industries.

If you are interested in exploring our products, we encourage you to get in touch with us promptly or visit our blog for additional information on the plastic industry.

About Bajaj Plast Pvt. Ltd.

Bajaj Plast Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.