Each type of additive masterbatch has some special properties to improve the end plastic product.

AntiFog Additive

Next-Gen Antifogging Additives for Precision-Controlled Film Clarity

Zero Fog. Maximum Shelf Impact. Trusted by Packaging Leaders Worldwide

Migration Stability

Optimized for controlled migration to avoid over-blooming or surface blooming during storage.

Long-Term Antifog Effect:

Effective in hot fog (refrigerated food packaging) and cold fog (greenhouse films) scenarios.

Synergistic Compatibility

Can be co-formulated with antistatic, slip, antiblock, and UV masterbatches.

Extend Freshness. Lead with Innovation

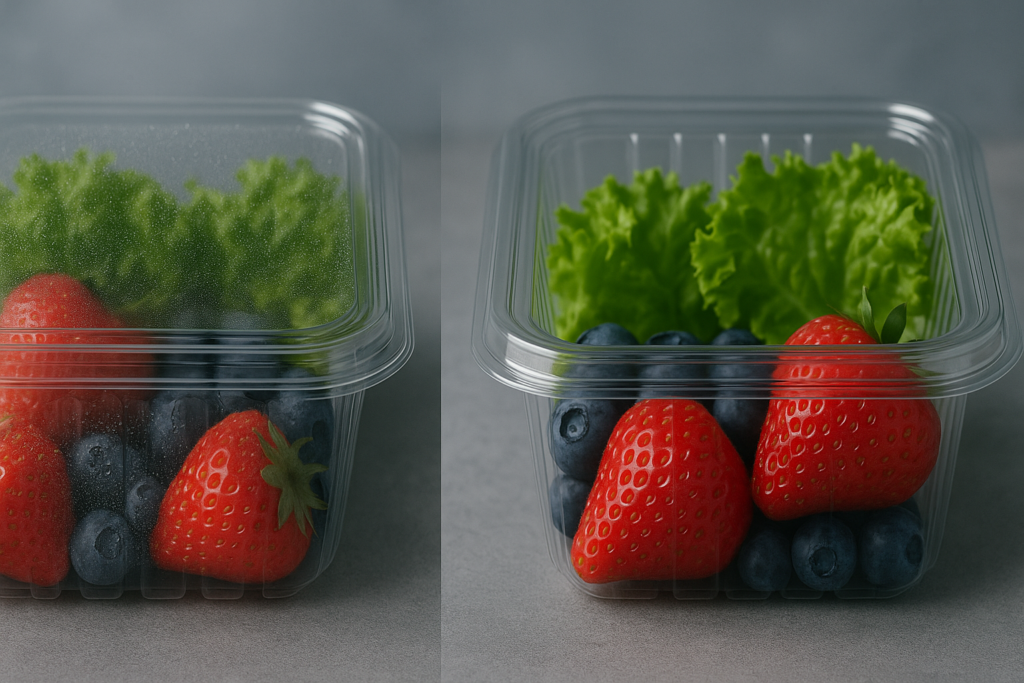

Clear Advantage in Packaging

Enables long-term antifog retention without visual or tactile surface distortion

Key Performance Metrics

Why AntiFog MB

Our Antifog Masterbatch is an advanced additive concentrate engineered to modify the interfacial energy characteristics of polymer film surfaces, thereby mitigating water droplet nucleation via controlled hydrophilicity enhancement. This formulation is optimized for integration into polyolefin-based substrates—namely LDPE, LLDPE, BOPP, CPP, and multilayer co-extruded films—used extensively in food packaging, horticultural coverings, and industrial sheeting.

The Antifog Masterbatch is a highly loaded concentrate of proprietary surface-active agents dispersed in a polyolefin-compatible carrier resin. Formulated with non-migrating surfactant systems, it ensures consistent fog suppression during storage, handling, and shelf-life, while maintaining high compatibility with polymer matrices.

The antifogging effect is achieved by modifying the surface energy of the polymer substrate. The surfactant molecules in the masterbatch migrate to the film’s surface during extrusion and lower the critical surface tension. This allows water vapor to form a continuous, uniform layer, maintaining transparency and preventing optical distortion caused by discrete water droplets.

The antifog masterbatch operates through surface energy modification by controlled migration of amphiphilic molecules to the polymer-air interface during film extrusion. This results in a thermodynamically stable monomolecular layer that facilitates continuous water sheeting rather than discrete droplet formation.

This interfacial tension reduction promotes a transparent hydrophilic film on condensation, ensuring maximum light transmittance and visibility through the film under fluctuating thermal and humidity conditions.

End-Use Applications

Food Packaging Films & Trays

Thermoformed trays, clamshell containers, stretch and shrink wraps, MAP (Modified Atmosphere Packaging) & vacuum packaging

Greenhouse Claddings

Enhances PAR (Photosynthetically Active Radiation) transmittance and suppresses disease vectoring via water droplets.

Prevent Fog. Preserve Appeal. Perform Better with Antifog Masterbatch Solutions