Woven Sack /

Raffia Applications

Bajaj Provides all types of Masterbatches & fillers required for woven sack/raffia Application. We do offer products solutions that involves Cost Optimization, Quality Consistency & Enhancement of properties required for the end product.

Our masterbatches are engineered to optimize raffia fabric production by reducing fabric weight without compromising strength, minimising process wastage, and enhancing output efficiency. This leads to significant reductions in both labour and electricity consumption per unit of production.

Advantages

Why Bajaj ?

Quality Consistency

Cost Benefit Ratio

Yields economical advantages to the manufacturer in terms of Cost Benefit ratio upon adding our filler with polymers in Tape plants with loading upto 60% on Polymer but not compromising on the product quality at any given point of time.

Increases Output

Increases output through production efficiency as the CaCO3 used in our formulation has good thermal conductivity to shorten the time required for each production cycle.

Improved Conversion Rates

With higher output rates and improved conversion rates, addition of our fillers results in increased operating efficiancies , all of which positively impact the bottom line of raffia manufacturer

Smooth Surface Finish

With exclusive combination in our recipe , we ensure good compatibility of polymer resin with CaCO3 filler it provides smooth surface finish to the end fabric as the dispersion is uniform while processing.

Unique features

Increase tape elongation and strength

No more water carrying issue

No powder formation

No tape breakage

High line speed low denier

Higher filler loading

Types of RAFFIA / Woven Sack

TARPAULIN

A tarpaulin is a large sheet of strong, flexible, water-resistant or waterproof & fire resistant material, often cloth such as canvas or polyester coated with polyurethane, or made of plastics such as polyethylene (LDPE & HDPE) . LDPE tarpaulin sheet is mainly used as a protective covering from harsh weather conditions for domestic and industrial purposes.

FIBC / JUMBO BAGS

A flexible intermediate bulk container, jumbo, bulk bag, super sack, big bag, or tonne bag is an industrial container made of flexible fabric that is designed for storing and transporting dry, flowable products, such as sand, fertilizer, and granules of plastic.

LENO BAGS

Leno weave (also called gauze weave or cross weave) is a weave in which two warp yarns of Polypropylene are woven around the weft yarns to provide a strong & sheer fabric. The standard warp yarn is paired with a skeleton or ‘doup’ yarn; these twisted warp yarns grip tightly to the weft which causes the durability of the fabric.

Geo Membrane

Advantages of Using Bajaj Rafia Solutions

Woven Fabric is strong

Woven cloth is flexible

Enhanced Strength

ease of storage & transportation

Resist tearing

food grade compliant

Uses of woven sack

- Agriculture

- Feed Industry -Storage & Transportation of feed products

- Construction

- Food

- Flood Control

- Tourism & Transport

- Geotechnical Packaging

- Chemical Packaging – Storage of crystalline & powdered chemicals

- For Military Fortification like trenches and bunkers And many more

Manufacturing PP Woven Sacks

The Process of involves following steps:

Trouble shooting guide

| PROBLEM | POSSIBLE CAUSES | SOLUTIONS |

|---|---|---|

| FILM PUNCTURE | Hold up particle | Change screen pack. Check Row Material Moisture. Check heat stability of master batch. |

| GELES, HARD OR UNPLASTICIZED PROFILE | Improper back pressure. Improper temp gradient. Moister in master batch. | Change temp. Profile. Use fine wire mesh. Reduce die lip opening. Reduce adaptor flow area. Change screw geometry. Pre-dry master batch. |

| DENIER VARIATION | Extruder surging. Film thickness variation across width. Spacer thickness variation. Improper drive Performance. | Refer problem III in general extrusion processing. Reduce throughput rate. Increase die volume. Adjust die lip. Check uniformity of die temp. Check spacer thickness. Use carbon steel blade. Check drive performance. Check temperature of orientation unit across width. Check flow velocity of hot air across width. |

| TAPE BREAKAGE | Excessive stretch ratio. Low orientation temp. Hold up particle in film. Very stiff film. Extruder surging | Increase stretch ratio. Increase orientation temperature. Refer problem of film puncture and gels, hard or unplasticized particles. Increase distance between die opening and water levels in tank. |

| LOW TENACITY / HIGHER ELONGATION | Low stretch ratio. Too soft film. Low orientation temp | Increase stretch ratio. Increase distance between die opening and water level in quenching tank. Increase orientation temp. |

| TAPE FABILATION | Tape too stiff Scratches on tape moving path. | Use anti fabrillation MB. Polish tape moving path. Use wear resistance material items. |

| SHRINKAGE IN FABRIC / CURVED TAPE | Residual stress in tape. | Check annealing system. Increase annealing temp. Check cooling efficiency of roller. |

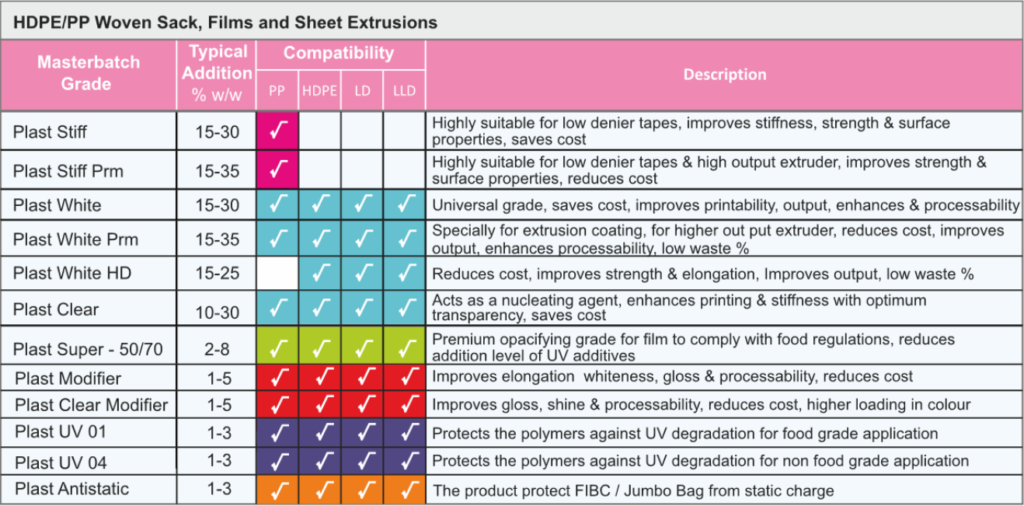

Bajaj solutions for woven sack industry

PLAST FILLER MASTERBATCHES SERIES

Plast modifier

Technical Features :

- Improves Whiteness

- Excellent Gloss, Shine & Luster

- Improves Dispersion

- Minimize Denier Variation

- Increase Strength

- Increase Elongation

- Increase Output

- Minimize formulation costs while enhancing end-product performance

- Less tape breakage with higher filler loading

- Faster line speeds and improved output

Plast white

Technical Features :

- Excellent anti-fibrillation

- Improve denier control of tapes

- Improve Anti-slip property

- Improve tenacity of tapes

- Improve film stability even at high speed

- Improve to print-ability

- Improve to heat resistant

- Improve productivity

- Impart Anti-blocking effect

- Improves whiteness hence saving of pigment

- Less abrasive to extruder & loom parts

- Cost reduction

Plast stiff

Technical Features :

- Excellent anti-fibrillation

- Less powder formation

- Improves Dimensional Stability

- Improves stiffness

- Anti-slip property

- Improves tenacity of tapes

- Improves cloth stability

- Better Heat Resistant

- Improves print-ability

Bajaj Plast Super / Tio2 series:

Features:

- Highly loaded (up to 75 %) premium TiO2 Masterbatches

- Food grade

- Good dispersion and process ability.

- It has highly weather abilities like weather-fast and non-yellowing, non pinking varieties (with bluish tinge).

- High refractive index

- Light scattering efficiency.

Bajaj Plast Additive Series

Bajaj Plast UV

In general Plastic woven sack are sensitive to sunlight, it’s exposure to UV radiations causes degradation of plastic .

read more

Our Plast UV masterbatch based on Hindered Amine Light Stabilizer (HALS) helps to extend durability of plastic products exposed to UV (Sun) radiation. This is the only product to sustainably decrease the reaction of degradation of plastic products which results in long life of the products. Plast UV are offered in food grade and non – food grade applications. Our UV Masterbatches can be used in production of Cement Bag, pp fabric, Laminated Bag, Tarpaulin,Fertilizer Bag, PP bag etcTechnical Features :

- Synergistic combination of oligomeric high molecular weight HALS

- Protects plastics from Photo degradation and long term heat exposure

- Low volatility, low migration and good resistance to extraction

- Low gas fading and low pigment interaction

- Suitable for applications requiring indirect food contact compliance

Plast Anti-Static

read more

This happens when polymers are subject to friction with other materials of similar or dissimilar nature (for e.g. metals) or their separation from other surfaces. When the charged polymer surface comes in contact with a neutral or oppositely charged surface (including humans) there is a possibility of spontaneous electrostatic discharge. A range of anti-static masterbatches can be offered depending upon the expected service life and level of surface resistivity reduction desired (usually resistivity of 109 Ohm/ Sq is achievable with regular antistats, we are working for 108 Ohm/Sq), relative humidity levels during use, regulatory requirements e.g. food approvals and criticality in post-processing such as surface printing and treatment.Features :

- Efficiently reduce resistivity.

- Long-acting anti-static effect.

- Performance will not be decreased by wiping or exterior friction. Good compatibility with various general & engineering plastic.

- Excellent dispersing ability.

- Pellet form, will not produce dust pollution.

- Reduce state charge of products, prevent electric shock.

- Increase added-value of products

- Resistant to water. Can still eliminate the buildup of static electricity

Plast Desiccant Masterbatch

Key Benefits :

- Reduction-elimination of moisture in recycled and reclaimed polymers

- Reduction-prevention of moisture related problems including:

- Lacing in films

- Porosity

- Windows / lenses in films

- Die build-up

- Surface defects in moulding

- Reduces surface defects such as

- lensing and fisheyes in films

- bubble breakage

- voids

- pin holes

- silver streaks in moulded articles

Plast Clear

Plast Clear is a talc base and formulated in PE carrier resin that acts as a nucleating agent, enhances printing and stiffness with optimum transparency of PP/HDPE/LDPE/LLDPE & recycled polymers. It also retains the transparency of the finished product. It increases mechanical properties in highly filled compound .

Key Benefits :

- Retains transparency in finished products while improving properties

- Even flow in processing by maintaining uniform back pressure

- Reduce post shrinkage of film

- Improve stiffness

- Improve Flexural Rigidity

- Better Draw-Down

- Improve Film structure with anti black property

- Improve Print-ability

- Improves adhesive lamination in multilayer film

- Better Opacity

- Increase machine output

Bajaj Plast colour series

Are you a Woven-sack manufacturer? Use Bajaj Masterbatches for your products