Silicone Masterbatches

Silicone Masterbatch

Bajaj Plast Silicone masterbatch series are pelletized formulation with ultra-high molecular weight siloxane polymer as the function part and different thermoplastic resins as the carrier, when used in the carrier compatible system, processing properties and pro-ducts surface quality can be effective improved

Better processing properties including better flow ability, reduce the extrusion die drool, less torque, improve the mold filling and release properties;

Typical performances

Better surface quality like slip surface, lower coefficient of friction, greater abrasion & scratch resistance;

Faster throughput, less product defect rate & Better stability than traditional processing aids

Silicone masterbatch is a kind of additive in the rubber and plastic industry. The advanced technology in the field of silicone additives is the use of ultra-high molecular weight (UHMW) silicone polymer (PDMS) in various thermoplastic resins, such as LDPE, EVA, TPEE, HDPE, ABS, PP, PA6, PET, TPU, HIPS, POM, LLDPE, PC, SAN, etc. And as pellets so as to allow easy addition of the additive directly to the thermoplastic during processing. combining excellent processing with an affordable cost. The silicone masterbatch is easy to feed, or mix, into plastics during compounding, extrusion, or injection molding. It is better than traditional wax oil and other additives in improving slippage during production. Thus, plastic processors prefer to use them in the output.

Roles of Silicone

Masterbatch additive in Improving Plastic Processing

The silicone masterbatch is one of the most popular choices for processors in plastic processing and surface quality improvements. As a kind of super lubricant. It has the following main functions when used in thermoplastic resin:

Improve the flow of resin and processing

Better mould filling and mould release properties

Reduce the extrude torque and improve the extrusion rate

Improves resin’s surface properties

Improve the plastic surface finish, smooth degree, and reduce the skin friction coefficient, Improve the wear resistance and scratch resistance;

And silicone masterbatch has good thermal stability and non-migration;

Effects on Final products

Due to the characteristics of the molecular structure of siloxane, the dosage is very small so on the whole almost no effects on the mechanical property of the final products. generally speaking, except elongation and impact strength will increase slightly, with no effects on other mechanical properties. At a large dosage, it has a synergistic effect with flame retardant agents.

Due to its outstanding performance on high and low-temperature resistance, it will no side effects on the high and low-temperature resistance of the final products. while the flow of resin, processing, and surface properties will be improved obviously and the COF will be reduced.

Action mechanism

Silicone masterbatches are ultra-high molecular weight polysiloxane dispersed in different carrier resins which is a kind of function masterbatch. When ultra-high molecular weight silicone masterbatches are added into plastics for their nonpolar and with low surface energy, it has a trend to migrate to the plastic surface during the melting process; while, since it has a large molecular weight, it can’t move out completely. So we call it harmony and unity between migration and non-migration. due to this property, a dynamic lubrication layer formed between the plastic surface and the screw.

With processing keep going on, this lubrication layer is constantly being taken away and produced. So the flow of resin and processing are getting improved constantly and reducing electric current, equipment torque and improving the output. After the processing of twin-screw, silicone masterbatches will be evenly distributed in plastics and form a 1 to 2-micron oil particle under the microscope, those oil particles will offer the products a better appearance, nice hand feeling, lower COF, and greater abrasion and scratch resistance.

From the picture we can see that silicone will become small particles after being scattered in plastics, one thing we need to point out is that dispersibility is the key index for silicone masterbatches, the smaller of the particles, the more evenly distributed, the better result we will get.

Environmental protection & Safety contact with the food.

Silicone Masterbatch ( Siloxane Masterbatch ) is a pelletized formulation with 20~65% ultra high molecular weight siloxane polymer dispersed in various resin carrier. It is widely used as an efficient processing additive in it’s compatible resin system to improve the processing properties and modify surface quality.

Compare to conventional lower molecular weight Silicone / Siloxane additives,like Silicone oil, silicone fluids or other type processing aids, Bajaj Silicone Masterbatch are expected to give improved benefits, eg,. Less screw slippage , improved mold release, reduce die drool, a lower coefficient of friction, fewer paint and printing problems, and a broader range of performance capabilities.

Silicone Masterbatch Application

Detailed Applications & Industry Usage

Film & Flexible Packaging

Polymers

LDPE, LLDPE, HDPE, PP (blown/cast/BOPP).

Applications

Shopping bags, stretch films, shrink wraps, multilayer laminates, agricultural films

Performance:

Reduces film-to-film friction (easy handling & winding).

Prevents blocking in stacked/wound rolls.

Maintains sealing integrity.

Improves film surface gloss and transparency.

Injection Molding

Applications

Automotive interiors, cosmetic packaging, appliance housings, closures, electronics.

Polymers

PP, PE .

Performance:

Enhances mold release and cycle efficiency.

Prevents surface scratches, stress marks, and flow lines.

Provides glossy finish with smooth feel.

Reduces part ejection forces.

Blow Molding

Polymers

HDPE, PP.

Applications

Bottles, containers, jerry cans, cosmetic packaging, industrial drums.

Performance:

Smoother surface finish and uniform wall thickness.

Better demolding in complex geometries.

Reduced cycle times.

Lower torque and energy requirement.

Extrusion & Thermoforming

Applications

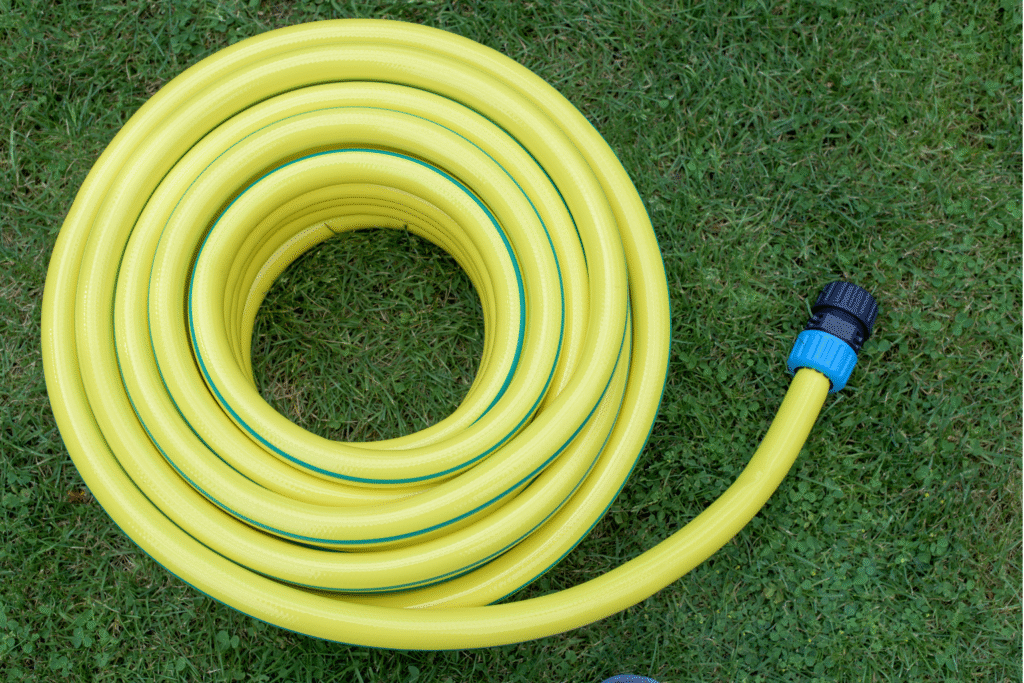

Rigid sheets, disposable trays, thermoformed packaging, pipes, profiles.

Polymers

PP, PE

Performance:

Eliminates melt fracture and flow instabilities.

Enhances surface gloss.

Reduces friction in thermoforming molds.

Improves dimensional stability.

Automotive Industry

Polymers

PP, PE.

Applications

Dashboards, trims, door panels, buttons, gear knobs, exterior trims.

Performance:

Provides soft-touch feel and luxurious finish.

Scratch and mar resistance in high-contact surfaces.

Anti-squeak property in interior assemblies.

Stable at high processing & service temperatures.

Electrical & Electronics

Applications

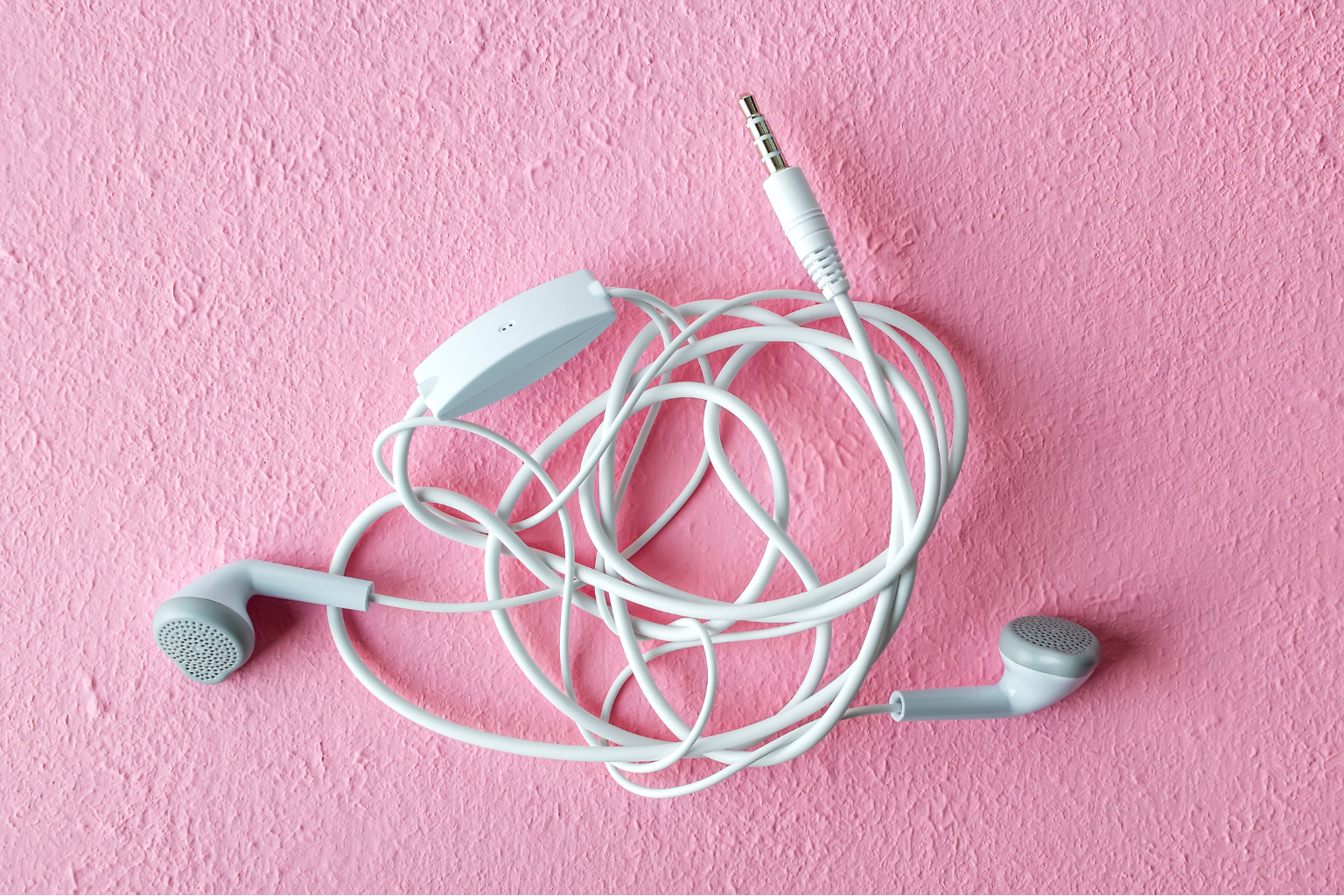

Wire & cable jacketing, plugs, connectors, appliance casings.

Polymers

PP PE .

Performance:

Smooth and durable insulation layer.

High abrasion resistance.

Consistent surface quality in molded casings.

Works with flame-retardant formulations.

Fibers & Nonwovens

Polymers

PP, PE.

Applications

Spunbond & meltblown nonwovens (hygiene, medical, filtration), carpet fibers, upholstery.

Performance:

Improved spinnability and reduced filament breakage.

Enhanced softness and drapability.

Stable fiber diameter and reduced static buildup.

Engineering Plastics

Applications

High-performance parts, transparent films, PET bottles, industrial components.

Polymers

PP , PE .

Performance:

Thermal stability at high melt processing temperatures.

Enhanced surface durability and scratch resistance.

Maintains clarity in transparent polymers.

Improves wear resistance of engineering-grade parts.

High-Performance Additives for Enhanced Processing & Surface Properties

Key Technical Benefits

Processing Improvements

Reduced torque load on extruders.

Lower melt viscosity and enhanced flow.

Reduced die drool, melt fracture, and sharkskin defects.

Improved demolding and part ejection in injection molding.

Energy savings due to reduced mechanical resistance.

Surface & Functional Benefits

Reduced CoF → enhanced slip properties.

Stable anti-blocking effect in multilayer films.

Scratch, abrasion, and mar resistance.

Silky smooth, soft-touch feel in molded parts.

High gloss and improved optical clarity.

Long-term stability without blooming or haze.

Compatibility Advantages

Maintains sealing strength in packaging films.

Works synergistically with antiblocks, antistats, and processing aids.

Compatible with PE, PP, EVA, PET, Nylon, and blends (ABS, PC/ABS).

Key Technical Features

Processing Aid

Enhances melt flow, reduces extruder torque, and minimizes die buildup.

Slip Modifier

Lowers Coefficient of Friction (CoF) between film surfaces and with metal rollers.

Mold Release Agent

Reduces part sticking during injection molding, enabling faster cycle times.

Surface Modifier

Provides silky smooth feel, scratch resistance, and glossy finish.

Anti-Scratch

Improves durability of high-gloss plastic surfaces.

Non-Migrating & Stable

Does not bloom like traditional amide-based slip agents.

Thermal Resistance

Withstands processing temperatures up to 300°C, suitable for engineering plastics.

Transparency-Friendly

Maintains clarity in transparent applications like films, bottles, and sheets.

Low VOC Emission

Environmentally friendly and suitable for sensitive applications (e.g., automotive interiors).

Food Contact Grades Available

Compliant with FDA food safety standards.