Bajaj PBT Masterbatch

PBT (polybutylene terephthalate) masterbatch is a specialized additive used in the plastic processing industry. It enhances the properties of PBT and other plastics during manufacturing, resulting in improved color, conductivity, and other characteristics in the final plastic product.

PBT Masterbatch: Enhancing Plastic Performance

Certainly! PBT additive masterbatches play a vital role in enhancing the properties and performance of PBT (polybutylene terephthalate) materials. Let’s explore some properties of PBT additive masterbatches:

Physical Properties

Provides dimensional stability and low moisture absorption. Exhibits good durability under thermal stress and harsh chemical environments (commonly seen in automotive underhood applications).

Mechanical Properties

Delivers high strength, toughness, and stiffness. Shows good practical impact resistance. Offers creep resistance over steady and elevated temperatures

Thermal Properties

High heat-deflection temperature and high-temperature index rating. Components made from PBT can withstand both short-term thermal excursions and long-term heat exposure.

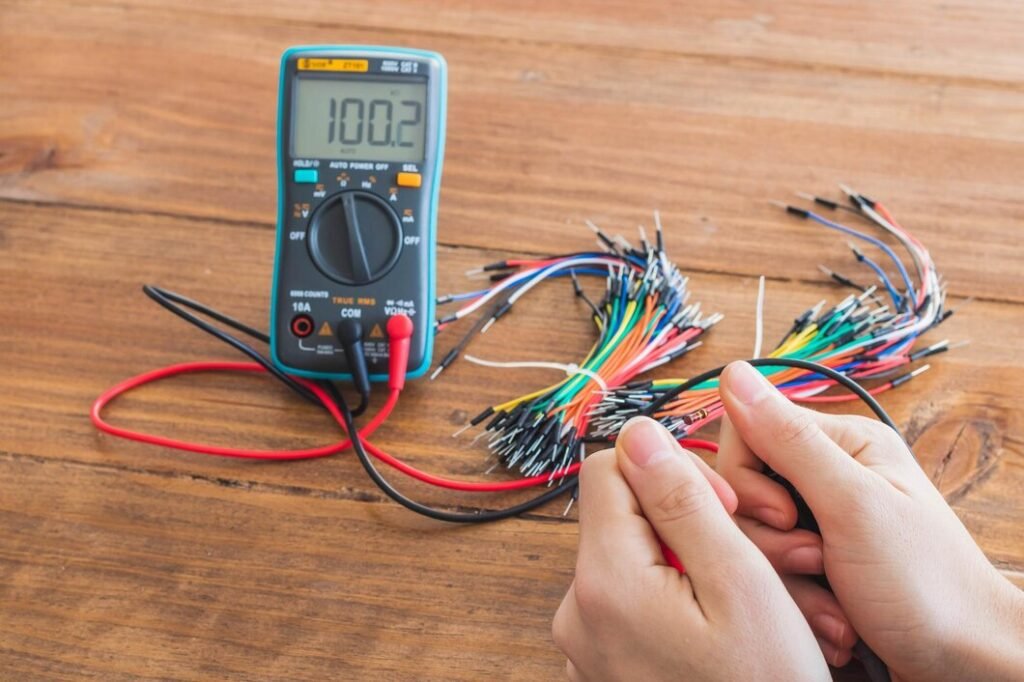

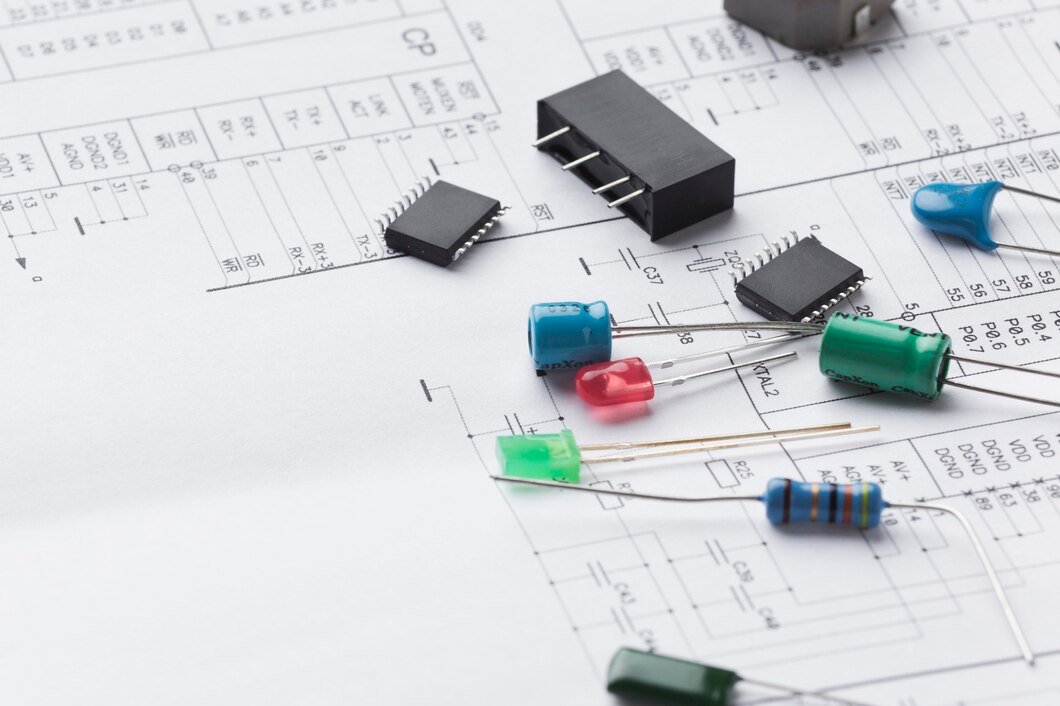

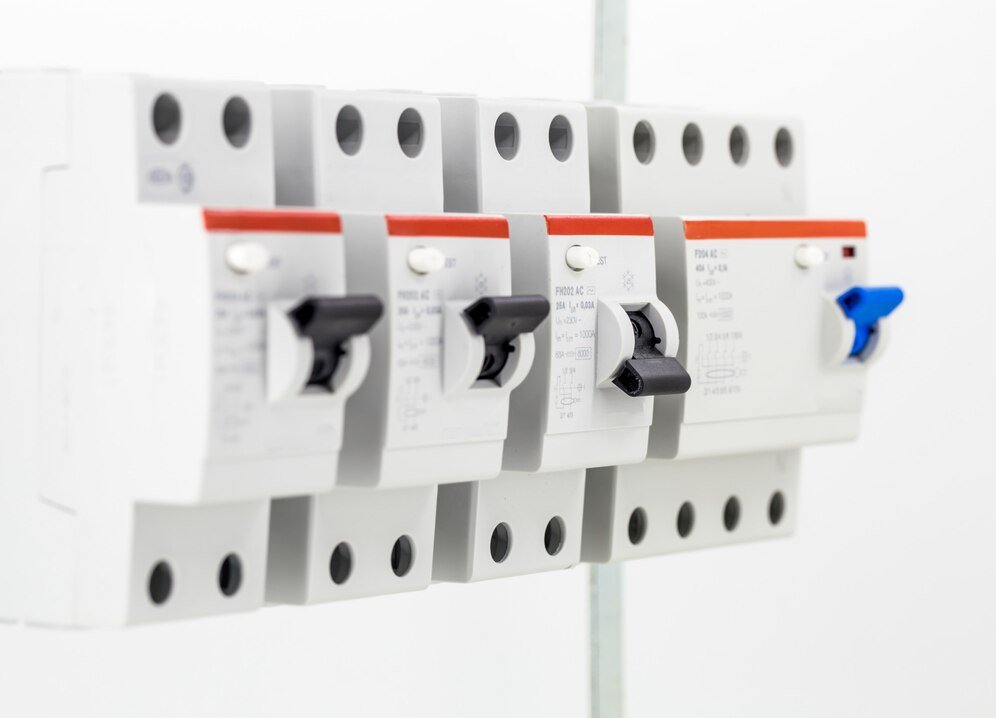

Electrical Properties

Protects electrical and electronic components against discharge. Provides high electrical resistance and dielectric strength. Guards against leakage and breakdown in power circuitry.

Key Features of PbT Masterbatch

Color Requirements

PBT masterbatches offer vibrant colors and excellent color consistency.

Functional Properties

Determine if you need electrical conductivity, UV resistance, or flame retardancy.

Compatibility

Ensure compatibility with your base polymer (PBT) and processing conditions.

Properties of PET Masterbatch

Color Enhancement

PBT masterbatch allows precise color customization. By adding specific pigments, manufacturers can achieve vibrant and consistent colors in their plastic products.

Electrical Conductivity

Some PBT masterbatches are designed for applications requiring superior electrical conductivity and electrostatic discharge (ESD) properties. These are particularly useful in electronic components and packaging.

UV Stabilization

UV-resistant PBT masterbatches protect plastic products from sun-induced degradation, ensuring longevity and performance.

Flame Retardancy

Certain PBT masterbatches contain flame-retardant additives, making them suitable for applications where fire safety is critical.

Processing Aid

PBT masterbatch aids in processing by improving melt flow, reducing processing time, and minimizing defects.

Applications of PET Masterbatch

Toys

Industrial components

Appliances

Insulating materials

Packaging

Electrical connectors

Switches

Automotive Parts

PBT masterbatch is a versatile tool for enhancing plastic performance. Whether you’re molding intricate automotive parts or creating consumer goods, the right masterbatch can make a significant difference