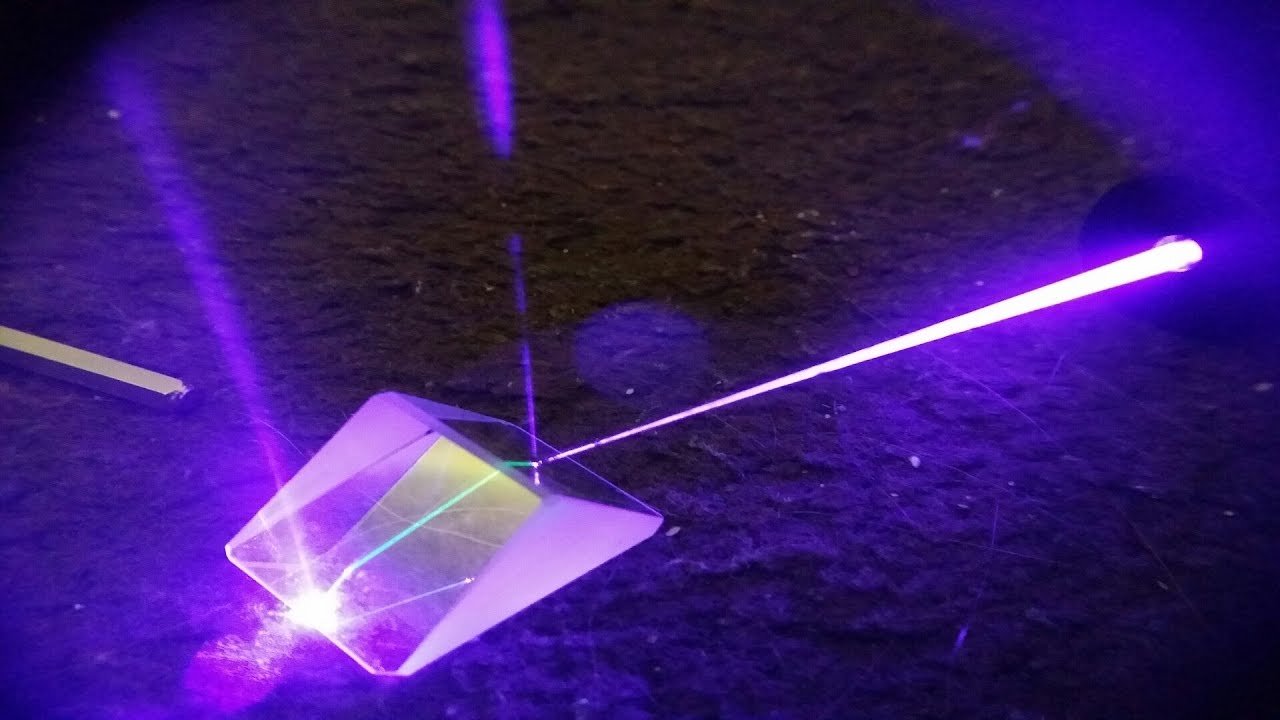

Bajaj LaserMark solutions are designed to produte dark or clear markings for complex projects featuring different color shades Sharp markings can be made on transparent or light-colored plastic parts with an NdYAG Laser, creating a mark that is heavy metal free and suitable for food contact applications

LaserMarkFlex is a portfolio of specific masterbatches designed for permanent ink free high definition using Nefrag techrungy in mono layer ansti coextruded film application LaserMark Fles allows Nigh flexibility nay personalization and serialization that makes it ideal for small batch sues and quick changing layouts.

Bajaj Laser Marking

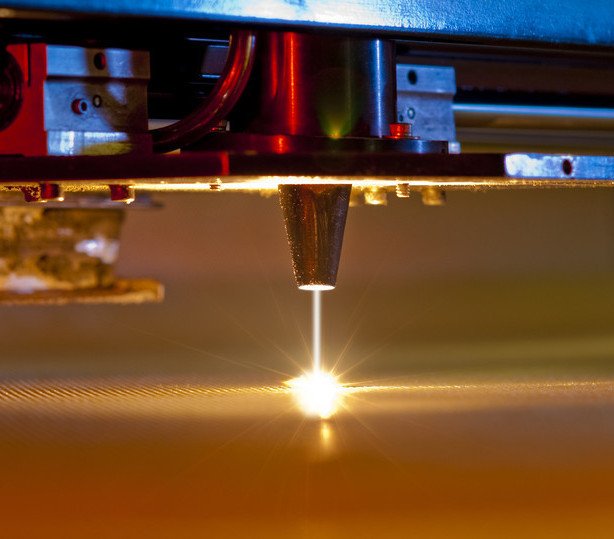

Bajaj laser marking products are compatible with most polymers and can be uned with all laser types to provide high levels of contrast and shading. These formulations achieve line detall at impressive speed on plastics that have historically been difficult to tases mark. Designed for thermal chemical surface reactions these formulations are ideal for fiber YAG. and vanadate lasers operating at a wavelength of 1060 1070.

Superior speed, definition, and high contrast levels for rigid and flexible applications

Bajaj can utilize additives, fliers, pigments, and dyes to enhance the absorption of later energy for localized color changes. Formulation chemistries and Laser optic configurations can be varied depending ovs the desired marking contrast and functionality FDA complaint formulations are available.

Common Application of Laser Marking Masterbatch

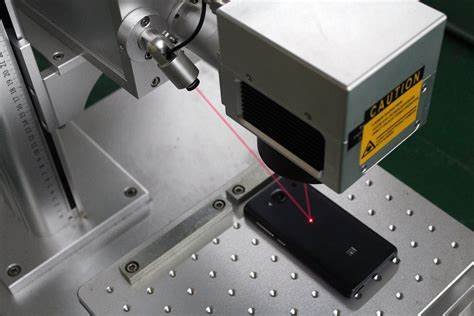

Product Branding and Labeling

Without the need for extra labels or printing, laser marking enables clear and accurate product labeling.

Traceability and Serialization

For tracking and traceability needs, laser marking can be utilized to generate distinctive identifiers like barcodes, QR codes, or serial numbers.

Laser Sensitivity

Additives in the laser marking masterbatch are laser light-sensitive at certain wavelengths. The laser energy is absorbed by these additives, which then react or change color, leaving a visible trace on the plastic surface.

Compatibility

The laser marking masterbatch can be used with a variety of polymers, such as acrylonitrile butadiene styrene (ABS), polyethylene (PE), polypropylene (PP), and polystyrene (PS). It can be added to the plastic while it's being manufactured without having a big impact on the original material's characteristics.

Accuracy and Repeatability

Laser marking masterbatch makes it possible to mark plastic surfaces accurately and repeatedly, giving producers great accuracy and repeatability while producing consistent results.

UV Resistance

Additives in the laser marking masterbatch are laser light-sensitive at certain wavelengths. The laser energy is absorbed by these additives, which then react or change color, leaving a visible trace on the plastic surface.