Bajaj Plast

Hydrophobic Masterbatch

Advanced Water-Repellent Technology for Enhanced Polymer Performance

Why Use Hydrophobic Masterbatch?

As the name indicates, hydrophobic masterbatches are designed to repel water or make the plastic product water-resistant. This masterbatch usually combines hydrophobic agents fluoropolymers which are combined in the resin to impart the properties. It is used in various applications such as films, sheets, and coatings. It can also be used to improve the processability of the end product, giving it better mechanical and physical capabilities.

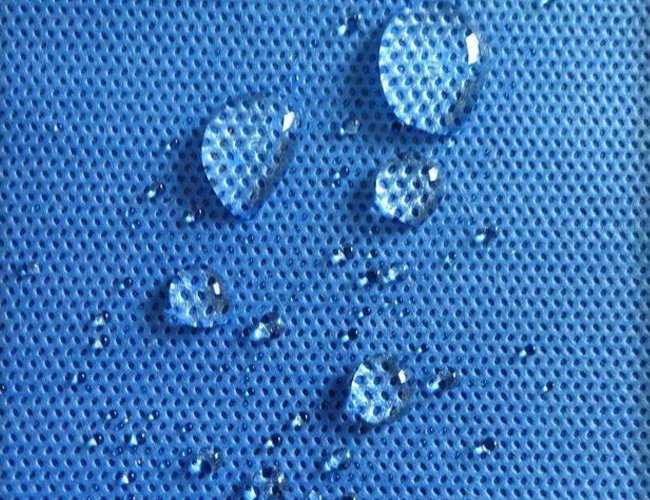

Permanent Hydrophobic,Oil resistant, alcohol repellency effect

Hydrophobic masterbatches form a permanent hydrophobic surface, achieving the effect of repelling water, oil, and alcohol. Plast Hydrophobic Masterbatch has good dispersibility and perfect filtration pressure FPV test results. It can provide a permanent resistance effect for polypropylene non-woven fabric or polypropylene fiber by replacing the post-treatment method.

Widely Use in Non woven , Films & Medical Applications

Polymer Compatibility

Suitable for use with polyethylene (PE), polypropylene (PP)

Easy Processing

Compatible with processes such as extrusion, injection molding, and blow molding.

Cost-Effective Protection

Improves durability of plastic products without requiring expensive coatings.

Water-shedding surfaces

Creates smooth, water-shedding surfaces, reducing staining, and maintaining aesthetic appeal.

Applications

NON WOVEN FABRICS

Hydrophobic MB offers excellent water, alcohol, and blood repellence to polypropylene nonwovens.

FILMS

Its ability to remove oil and water from packaging and manage oil spills makes it a valuable component in the film industry

MEDICAL PRODUCTS

Medical equipment used in this field are water-resistant since they come in touch with various bodily fluids.

AUTOMOTIVE

A protective layer that repels water, dirt, and other impurities from a car's paint, glass, wheels, and plastics.