Blown Film

Bajaj Provides all types of multilayered applications with product solutions like cost, quality & properties etc. We also facilitate high efficiency and fast production, multilayered packaging is often opaque due to metal films used. It has the ability to prevent light penetrating products inside the packing. Multilayered packaging increases the shelf life of edible products. Bajaj Masterbatch provides customized products as per customer requirements.

Monolayer films

Monolayer film is produced with a single film layer typically comprises of polymer resins such as LDPE, LLDPE, HDPE, PP, EVA , EVOH, PA , etc.

They are widely used in Garbage bags, grocery bags, construction films, agricultural films, liners , garment bags, refuse bags, diaper films, wrappers for food products, health care packaging, dairy packaging, etc.

It involves low cost investment with low power consumption , optimum level of output yielding good ROI especially in the packaging segment.

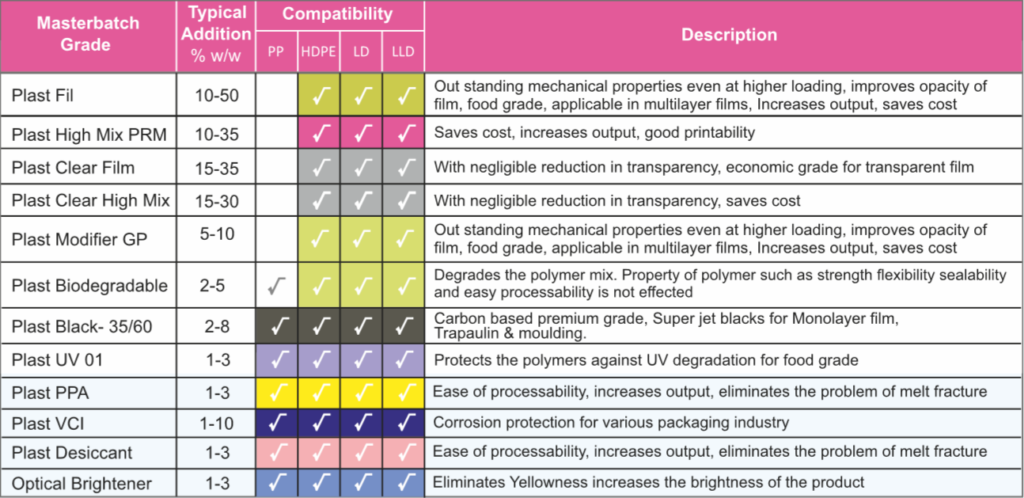

We have wide range of masterbatches to cater this segment , they are :-

Multilayer films

Multilayer films

Multilayer Films

It comprises of 2 to 7 layers of blown films manufactured by co-extrusion process such that every layer imparts required characteristic property such as barrier , heat sealability, stiffness , impermeability and so on. Generally outer layers are thin layers consisting of high priced polymer chosen for specific end applicaiton requirements whreas middle and inner layers are chosen for performance , cost-saving , etc.

By and large our masterbatches are used in multilayer films catered for Flexible packaging widely used in FMCG and also other non food applications such as Agriculture, E-tailing, Construction, Industrial liners and so on.

Our Product offerings are :-

Advantages of Using Bajaj Film Solutions

Complex Part Design

High Efficiency- Fast Production

Enhanced Strength

Flexibility- Material and Color

Reduced Waste

Low Labor Costs

WHY BAJAJ FILLERS ?

Benefits of Bajaj Masterbatch

Heat Stability

Light fastness

UV Stability

Environmental Stability

Food Contact Application

Product Solutions for Blown Film Application

Color Masterbatch

for Blown Film Applications

White Masterbatches

for Blown Film Applications

Black Masterbatch

for Blown Film Applications

Transparent Masterbatch

for Blown Film Applications