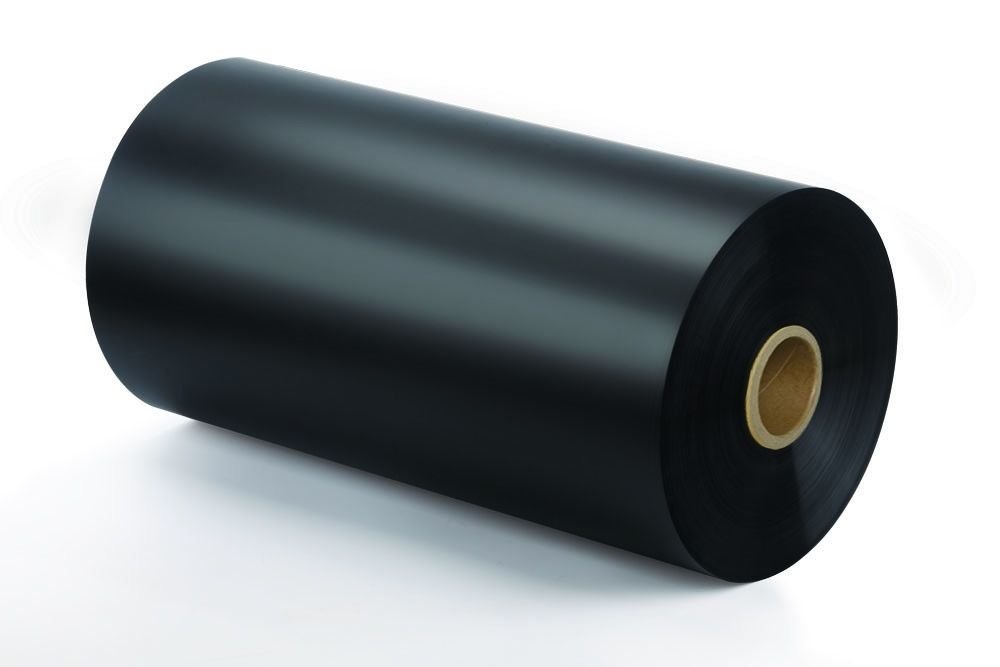

Conductive Masterbatch

Conductive masterbatch is created by blending a base resin material with carbon black and other additives. During processing, this masterbatch is mixed with the base material in specific ratios to enhance the conductivity or anti-static properties of the resin. It’s a versatile tool that finds applications in various industries and processes.

The primary purpose of conductive masterbatch is to provide electrical conductivity in plastic applications, particularly for static charge dissipation

Conductive Masterbatch Advantages

Ease of processability

High jetness

High gloss

UV protection

Why Bajaj Plast Conductive Black Masterbatch

Key Features:

- It is used for conductive application to discharge the surface electricity and earthing.

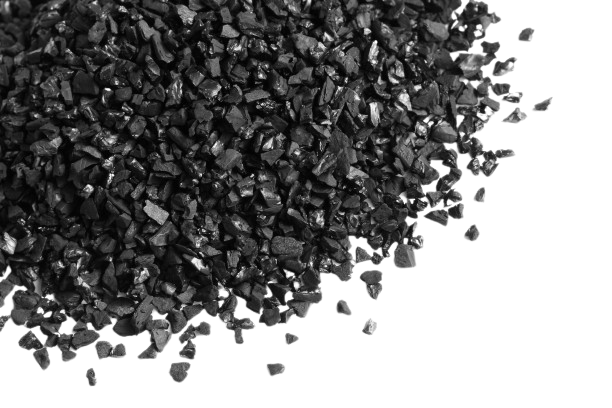

- Carbon Black is used as an additive

Carbon Black and Formulation Masterbatch

- Carbon black, a key component, contributes to the conductive properties. It’s formulated with precision to achieve consistent quality, excellent dispersion, and specific performance characteristics.

- conductive compounds offer benefits such as opacity, color strength, UV weathering resistance, and, most importantly, electrical conductivity.

Typical Applications Of Masterbatch

Anti-Electromagnetic Interference

Conductive masterbatch is widely employed to mitigate electromagnetic interference (EMI) and radio frequency interference (RFI).

Antistatic Properties in Electronic/Micro-Electronic Devices

In the realm of electronics and micro-electronics, conductive masterbatch plays a crucial role in imparting antistatic properties to plastic materials.

3D Printing

Conductive masterbatch is compatible with 3D printing processes

Petroleum and Chemical Industries

Conductive masterbatch is valuable in environments where flammable gases or liquids are present.

Military and Aerospace Applications

The military and aerospace sectors rely on conductive masterbatch for various purposes.