Blowing Agents Make More out of Your Plastics

Chemical blowing agents are used in a wide range of applications to achieve various positive effects. Being reactive

additives, they release gases in a thermal decomposition reaction during the processing of thermoplastics. These enable the production of a stable plastic foam.

Chemical blowing agents are generally classified as either endothermic or exothermic systems, each of which follow different decomposition reactions and have different propertie

Bajaj Plast Blowing Agent

Blowing agent-Masterbatches are available in different active substance concentrations. In addition, special blowing agent masterbatches contain slip agent components, in order to achieve an optimal foam structure in case of long floating ways or to ensure a trouble-free de-molding

Packaging Foam

Foamed plastics produced with blowing agent

masterbatch are used in the manufacturing of footwear, athletic padding, and sports equipment.

These materials provide cushioning and impact resistance properties

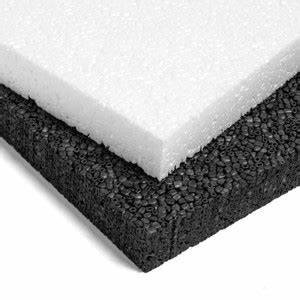

Soundproofing and Acoustic Materials

Foamed plastics produced with blowing agent

masterbatch find applications in soundproofing and acoustic materials for buildings, studios, and

industrial environments.

Blowing Agents for LLDPE

When it comes to Low-Density Polyethylene (LLDPE), blowing agents play a crucial role in creating foamed structures. These agents help generate gas bubbles within the polymer matrix during processing, resulting in lightweight and insulating materials.

Blowing Agents for LDPE

Low-density polyethylene (LDPE) foams blown with CO2 typically present severe shrinkage problems, which makes them have to be produced by using hydrocarbon as the blowing agent.

Blowing Agents for HDPE

When it comes to High-Density Polyethylene (HDPE), blowing agents play a crucial role in creating foamed structures. Let’s delve into the world of these fascinating additives: Genitron, Azo Compounds, Structural Foam, Endothermic Blowing Agents.

Blowing Agents for PE

The chemical blowing agent plays a crucial role in enhancing the performance of the polyethylene (PE) foaming resin during the rotational foaming process. Previously, the conventional blowing agent of the PE resin commonly used pure azodicarbonamide (AZ).

These masterbatches are specifically designed to improve light diffusion while maintaining optical clarity. If you have specific requirements, feel free to consult with manufacturers or suppliers to find the right solution for your application

Eliminates Hot Spots

By scattering light, these masterbatches eliminate concentrated areas of intense brightness.

High Light Diffusion

They effectively disperse light, making it more uniform and gentle.

Lower Refractive Index

This property contributes to better light diffusion

Very Good Dispersion

Ensures consistent performance throughout the material.

Energy Saving

By diffusing light effectively, they contribute to energy efficiency.

High Heat Stability

Suitable for various processing methods like injection molding and extrusion