We provide industry-specific, quality-tested masterbatches in seven main categories for almost all types of polymers.

PLAST RED

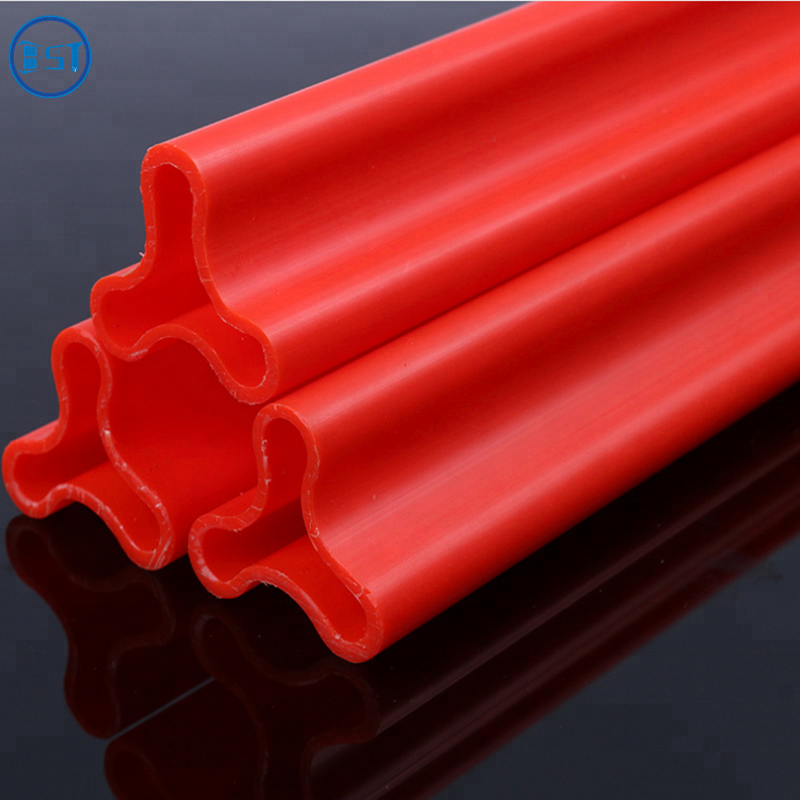

Extrusion Applications

Bajaj Plastic extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

Why Bajaj Color Masterbatches?

Color and opacity performance can vary with thickness, letdown, polymer selection and processing conditions, however we offer complete solutions to our clients to determine their suitability for specific applications. We are committed to offer our wide range of Colour masterbatches to add value in customer’s business emphasizing our motto

PLAST RED

For

Consumer & Household Products

PLAST RED

For

Consumer & Household Products

Advantages of Bajaj Color Masterbatches

Heat Stability

Light fastness

UV Stability

Environmental Stability

Need For Extrusion

This is most common plastic processing technique used for manufacturing a wide variety of plastic items ranging from smallest components like Caps, buttons, Electrical & Electronic parts, buttons, etc to large components like Car bumper , dash board, Home Appliances body , etc.

When looking for a high-volume injection molding process, it’s important to consider companies’ green manufacturing initiatives, as these signify a commitment to quality, sustainability, and optimal safety.

Advantages of Using Bajaj Extrusion Solutions

Complex Part Design

High Efficiency- Fast Production

Enhanced Strength

Flexibility- Material and Color

Reduced Waste

Low Labor Costs

Plast Red Colour Range

It is used for giving different red colour shades to the plastic.

Plast Red 903

Plast Red 904

Plast Red 905

Plast Red 906

Plast Red 907

Plast Red 908

Plast Red 909

Plast Red 910

Plast Red 911