SLIP ADDITIVE

Prevents sliding over itself or with equipment.

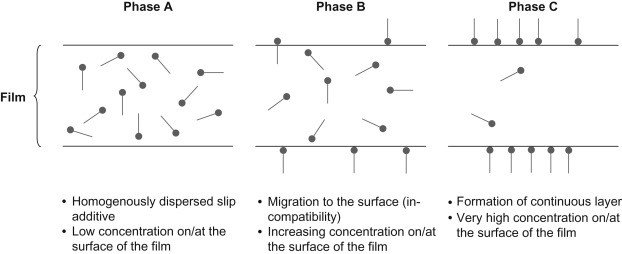

Slip additives are products which can be added to polymers to

control friction. They are added directly into the polymer during the

extrusion process and migrate to the surface as the polymer cools,

allowing a solid lubricating layer to form.

Know more

They can be used in Polymer film structures and plastic packaging to improve polymer processing and in-use properties and are a practical requirement for both the manufacturer and end-product consumer.

Reduces coeff. of Friction

Slip additives are products which can be added to polymers to

control friction. They are added directly into the polymer during the

extrusion process and migrate to the surface as the polymer cools,

allowing a solid lubricating layer to form.

Know more

They can be used in Polymer film structures and plastic packaging to improve polymer processing and in-use properties and are a practical requirement for both the manufacturer and end-product consumer.

Role of Slip additive during Extrusion process

How it Works?

Slip or surface friction, expressed as Coefficient of Friction or CoF, measures the interaction between two polymer surfaces, or, between the polymer surface and extruder. There are several factors affecting the development of friction such as :

- Polymer type

- Process temperature and type

- Film gauge and structure

- Other present additives

Effects of slip additives

Traditional organic slip additives are based on unsaturated fatty acid amides. These primary amides, which have low molecular weights, migrate rapidly through polyolefin films after extrusion and appear on the surface of the film to lower the COF. These additives are also characterized by exudation – the formation of a gel-like layer that can transfer to other film surfaces, lead to haze and affect printing operations.

Know more

Unlike these organic slip additives, silicone technologies have higher molecular weights, so they move to the surface of the film more slowly. Importantly, they provide some anchoring to the resin matrix at the surface to deliver stable COF reduction, and will not cause exudation.

Our newest silicone solutions are designed to deliver improved anchoring and are suitable for both BOPP and cast films used in bags, wrappers, packages and pouches. Some can be used in sequential and simultaneous BOPP processing.

With growing trends towards faster production rates for cost reduction with eye-catching graphics in flexible packaging industry , both depend upon the properties of advanced slip agents, which are used to reduce the coefficient of friction (COF) in bi-axially oriented polypropylene (BOPP) film. Slip agents / additives, overcome the film’s natural tackiness, enabling it to move smoothly through high-speed converting and packaging equipment.

| Product | Description | Download TDS |

|---|---|---|

| Plast Slip | Slip additives are products which can be added to polymers to control friction. Excellent printability , faster winding & unwinding of films. | Download TDS |

Significant advantages of Plast Slip

Ease of Processing

Smoothness in substitute

Cost Optimization

Whats New?

Value Addition