PBAT Plastic

What Are PBAT Plastic and Its 6 Applications?

The harm caused by unrecyclable plastic to the environment is significant and widespread. According to a report by the World Economic Forum, there could be more plastic than fish in the ocean by 2050 if current trends continue to rise. Not only that, but plastic waste in the ocean harms marine life. It can equally enter the human food chain because fish and other aquatic organisms consume tiny particles known as microplastics. Considering that, one study estimates that people who eat seafood ingest up to 11,000 pieces of microplastic each year.

To combat this problem, there is a growing interest in eco-friendly alternatives to traditional plastics. One alternative is PBAT (PBAT’s complete form is polybutylene adipate terephthalate), which refers to a biodegradable polymer from renewable resources like corn starch and vegetable oil. Let’s explore what PBAT plastic is, what it offers, and how it works in various applications.

What Exactly Is PBAT Plastic?

PBAT, a random copolymer, is a biodegradable substance comprising a copolyester of adipic acid, 1,4-butanediol, and terephthalic acid (derived from dimethyl terephthalate). This material may also be called poly(butylene adipate-co-terephthalate), occasionally polybutyrate-adipate-terephthalate, or simply “polybutyrate.” PBAT, or polybutylene adipate terephthalate, is marketed as a fully biodegradable substitute to low-density polyethylene and has similar properties, such as flexibility and resilience, making it suitable for applications like plastic bags and wraps.

What Are the Benefits of PBAT Plastic?

Here are some of the notable benefits offered by PBAT plastic:

Good Ductility

PBAT (polybutylene adipate terephthalate) is a type of biodegradable plastic known for its good ductility, which refers to a material’s ability to deform under stress without breaking. PBAT has a relatively high elongation at break, which means it can stretch without breaking. For example, PBAT films can stretch up to 350% of their original length before breaking, and this property makes PBAT plastic ideal for flexible packaging applications, including food packaging or compostable bags.

Good Elongation at Break

PBAT has an excellent elongation at break, which means that it can stretch considerably before breaking. The elongation at break for PBAT can range from 100% to 700%. For instance, PBAT fibers may have an elongation at a break of around 200%, and this property makes PBAT plastic suitable for applications requiring high flexibility and stretchability, such as disposable gloves or stretch wrap.

Excellent Biodegradability

One of the most significant benefits of PBAT plastic is its excellent biodegradability – PBAT is a biodegradable polyester that can decompose under aerobic and anaerobic conditions. The biodegradation rate of PBAT can vary depending on the environmental conditions, but it typically takes 60 to 120 days for PBAT to biodegrade in soil or compost completely. Meanwhile, this property helps PBAT plastic to become an ideal choice for applications that require sustainable and eco-friendly materials, incorporating single-use packaging or disposable cutlery.

Good Heat Resistance

PBAT has good heat resistance, meaning that it can withstand high temperatures without degrading or losing its physical properties. The melting temperature of PBAT is around 160-170°C, and its glass transition temperature is around -30°C, which makes PBAT plastic suitable for applications requiring high-temperature resistance, like microwaveable food containers or hot drink cups.

How Does PBAT Work in Its Applications?

In this section, we will have a look at how PBAT plastic works in numerous applications:

Shopping & Express Bags

The production of shopping bags, express bags, and other forms of packaging that are intended to be used just once may be accomplished with the help of PBAT plastic or polybutylene adipate terephthalate plastic. Essentially, these bags are able to be composted once they have been used, meaning that they produce less waste and have less effect on the environment

Packaging Films

PBAT may also be used in the production of many types of packaging films, some of which are utilized in the food, cosmetics, and pharmaceutical sectors. In addition to being able to shield objects from moisture and oxygen, these films are also biodegradable and may be composted.

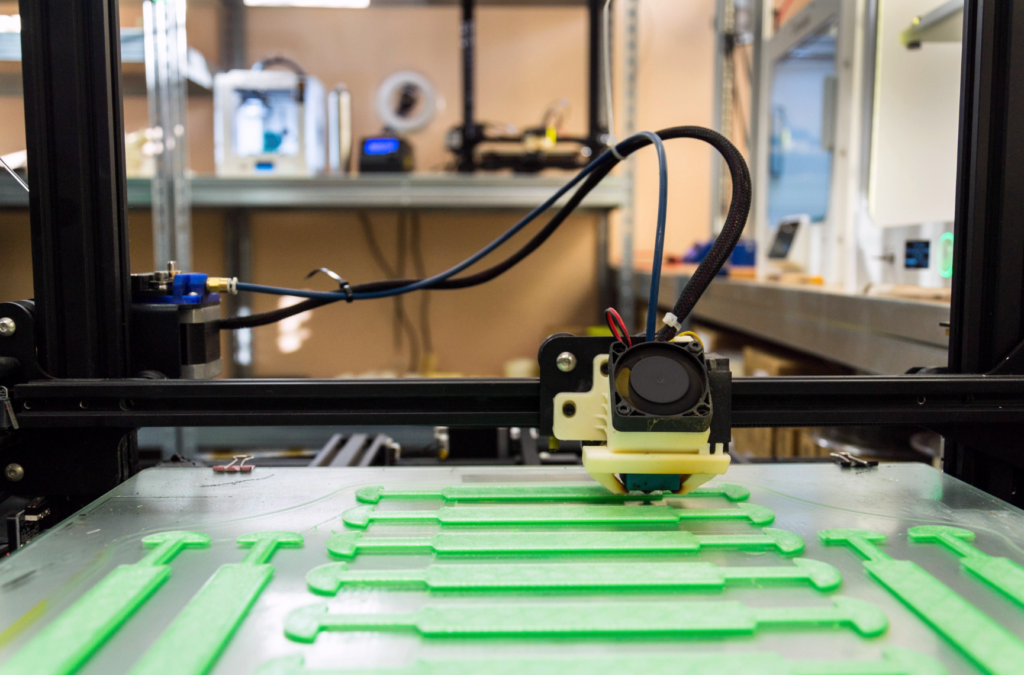

3D Printing Material

PBAT may be used as a filament in 3D printers, which enables the development of 3D-printed objects or products that serve the purpose of biodegradability and compostability. Eventually, these products have applications in many different fields, such as the packaging industry, the consumer products sector, and the medical supply sector, among others.

Agricultural Films

The production of agricultural films, which are used to cover crops and shield them from both insects and severe weather, may be accomplished with the help of polybutylene adipate terephthalate plastic. These films may also be biodegradable and compostable, which will ultimately help cut down on the amount of trash produced by the agricultural sector.

Disposable Tableware

The production of disposable tableware, such as plates, cups, and utensils, may be completed with the use of PBAT plastic. Since these goods may be composted after use and are biodegradable, they contribute to a reduction in waste in the food service business.

Disposable Medical Supplies

PBAT polymer or plastic may be used in the production of a variety of one-time-use medical products, including but not limited to gloves, gowns, and masks. Since these goods are compostable and biodegradable after they have been used, they help the healthcare sector save resources while simultaneously meeting rigorous safety and hygiene requirements.

About Bajaj Polyblends Pvt. Ltd.

Bajaj Polyblends Pvt. Ltd. is a leading manufacturer of high-quality masterbatch solutions, dedicated to innovation, sustainability, and excellence. With a strong focus on customer satisfaction and cutting-edge technology, we are committed to delivering superior products that meet the evolving needs of the polymer industry.